A kind of genetically engineered bacteria with high lipopeptide production and its application

A technology of genetically engineering bacteria and lipopeptides, applied in the field of genetic engineering, to achieve the effect of increasing the production of lipopeptides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

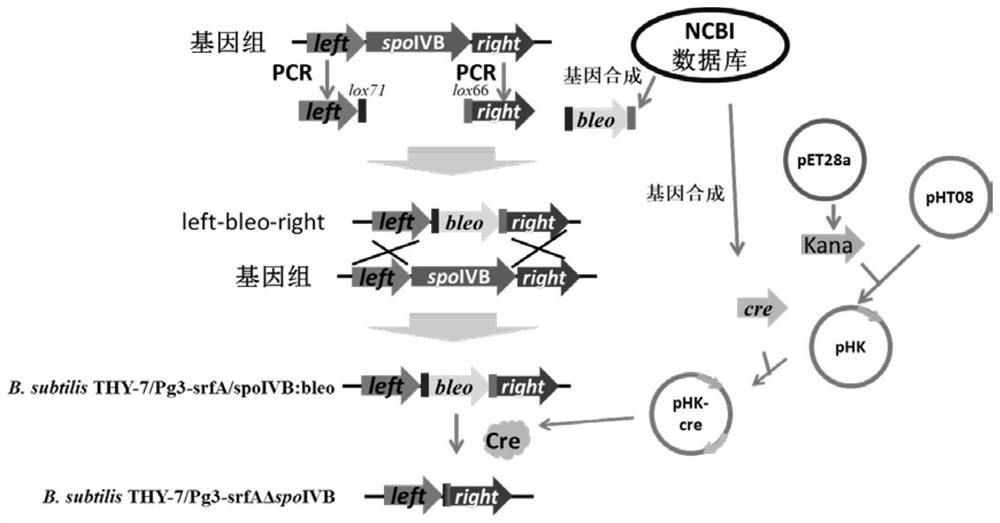

[0078] Example 1 is used to knock out the construction of the linear fragment left-bleo-right of the spore gene

[0079] Build process such as figure 1 As shown, the spoIVB gene and the bleomycin resistance gene are taken as examples.

[0080] According to the p7z6 plasmid sequence (NCBI: EU541492.1) published on the database NCBI, the bleomycin resistance gene fragment bleo, 650bp, with lox recognition sites at both ends was synthesized.

[0081] The Bacillus subtilis THY-7 genome was extracted using the Bacterial Genome Extraction Kit from Omega. Using the obtained genome as a template, PCR amplification was performed using the upstream primer left-F and the downstream primer left-R to obtain the left fragment of the homology arm located upstream of the spoIVB gene in the genome. With the THY-7 genome as a template, use upstream primer right-F and downstream primer right-R to carry out PCR amplification to obtain the homology arm right fragment located in the downstream of t...

Embodiment 2

[0130] Example 2 Construction of spoIVB-deficient genetically engineered bacteria

[0131] The left-bleo-right fragment used for knocking out the spoIVB gene constructed in Example 1 was transformed into competent cells of Bacillus subtilis THY-7 and THY-7 / Pg3-srfA by electroporation to obtain spoIVB-deficient cells Genetically engineered bacteria THY-7 / spoIVB:bleo, THY-7 / Pg3-srfA / spoIVB:bleo. Wherein, the preparation and electrotransformation of Bacillus subtilis THY-7 / Pg3-srfA competent cells adopt the method in Chinese patent document CN105400784A.

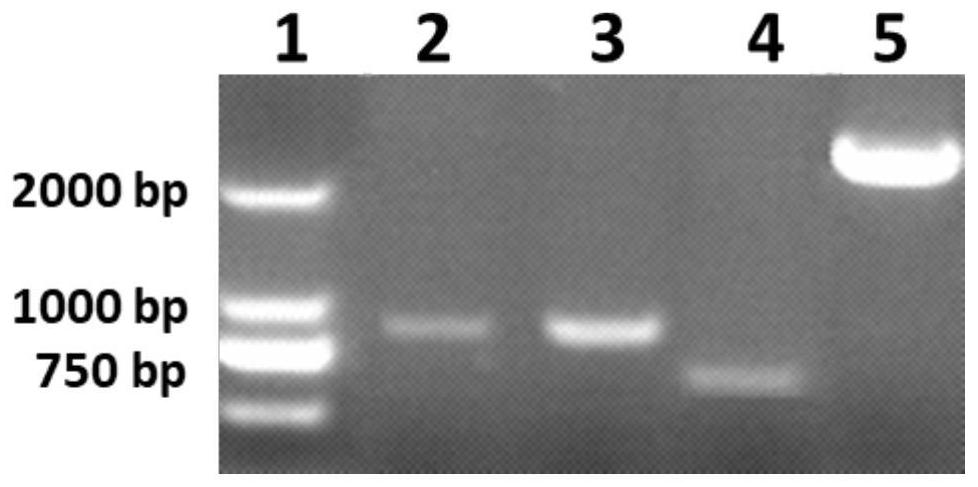

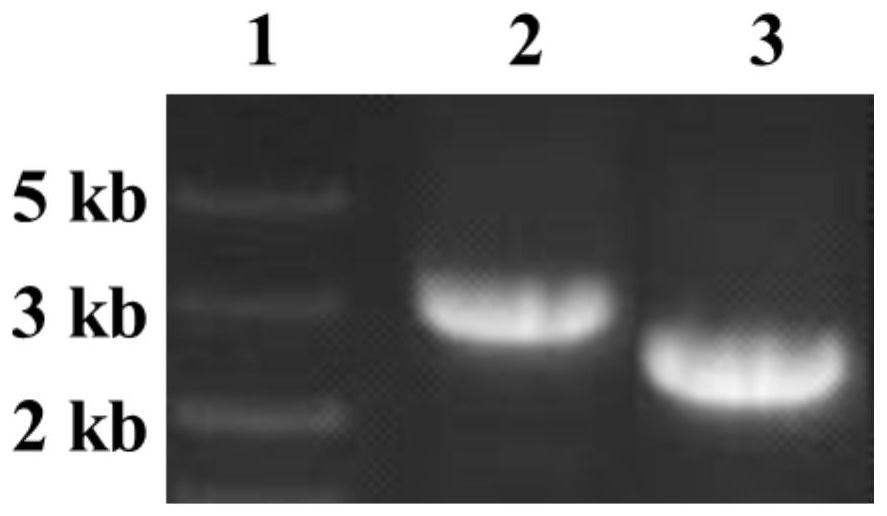

[0132] After thawing, take 100uL of the bacterial liquid and spread it on the LB solid medium containing 10-30μg / mL bleomycin, and place it upside down in a 37°C incubator for overnight culture, pick a single colony, and use the upstream and downstream primers left-F and right -R for PCR verification. At the same time, the genome of the original strain was used as a template and PCR with the same primers as a control. The orig...

Embodiment 3

[0137] Example 3 Production of lipopeptide surfactant—surfactin using genetically engineered bacteria B.subtilis THY-7 / Pg3-srfAΔspo0A

[0138] The genetically engineered bacteria THY-7 / Pg3-srfAΔspoOA of the spore-deficient type obtained in Example 2 was inoculated in LB liquid medium, and cultivated for 16h at 37°C and 200rpm to obtain the genetically engineered bacteria liquid;

[0139] Insert 5% into the shake flask equipped with 100mL fermentation medium, add 1mM IPTG when cultivating for 2-6h under the conditions of 37°C and 200rpm, continue to cultivate until 2d, and the fermentation ends.

[0140] The composition of the fermentation medium used is: sugar 30-100g / L, inorganic nitrogen source 10-50g / L, organic nitrogen source 0.5-3g / L, KH 2 PO 4 0.1-1g / L, Na 2 HPO 4 12H 2 O 0.5-0.3g / L, CaCl 2 0.002-0.01g / L, MnSO 4 ·H 2 O 0.002-0.01g / L, FeSO 4 ·7H 2 O 0.002-0.01g / L, pH 6.5-7.5.

[0141] Microscopic observation of cell spore morphology during the fermentation pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com