A kind of concrete and preparation method thereof

A concrete and mass fraction technology, applied in the field of building materials, can solve problems such as large density difference, easy to block pipes, aggregate sinking, etc., and achieve the effect of improving fluidity, not easy to crack, and easy to mix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

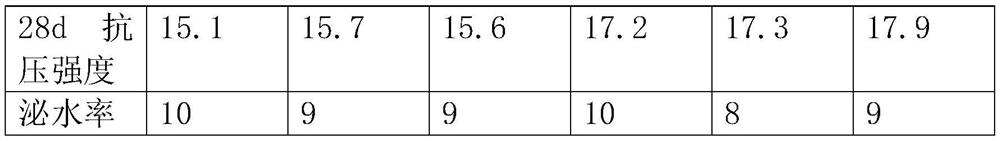

Examples

Embodiment 1

[0050] A concrete comprising the following components in parts by mass:

[0051] Portland cement 22.5kg; water 45kg; sand 22.5kg; stone 37.5kg; sulfamate superplasticizer 1.35kg; carboxymethyl cellulose 0.15kg; silane coupling agent 7.5kg.

[0052] In this embodiment, the viscosity of carboxymethyl cellulose is 6000 mPa.s.

[0053] In this embodiment, the silane coupling agent adopts 3-aminopropyltrimethoxysilane, and in other embodiments, the silane coupling agent can also adopt N-phenyl-3-aminopropyltrimethoxysilane, N -(2-Aminoethyl)-3-aminopropyltrimethoxysilane and the like.

[0054] Concrete is prepared as follows:

[0055] (1) Add 22.5kg of sand and 37.5kg of stone to the sand and gravel mixer at room temperature, and stir at a speed of 200r / min. After stirring evenly, aggregates are obtained;

[0056] (2) Add Portland cement 22.5kg while stirring, after stirring evenly, obtain the premix;

[0057] (3) Put the uniform premix in step (2) into the concrete mixer. Unde...

Embodiment 2

[0059] A concrete comprising the following components in parts by mass:

[0060] Portland cement 27kg; water 52.5kg; sand 27kg; stone 44kg; sulfamate superplasticizer 1.6kg; carboxymethyl cellulose 0.18kg; silane coupling agent 8.7kg.

[0061] In this embodiment, the viscosity of carboxymethyl cellulose is 6000 mPa.s.

[0062] In this embodiment, N-phenyl-3-aminopropyltrimethoxysilane is used as the silane coupling agent.

[0063] Concrete is prepared as follows:

[0064] (1) In the gravel mixer, under normal temperature conditions, add 27kg of sand and 44kg of stone, and stir at a speed of 200r / min. After stirring evenly, aggregates are obtained;

[0065] (2) Add Portland cement 27kg while stirring, after stirring evenly, obtain the premix;

[0066] (3) Put the uniform premix in step (2) into the concrete mixer, and stir at a speed of 200r / min under normal temperature conditions, and add 52.5kg of water and sulfamate-based high-efficiency water reducer while stirring 1.6k...

Embodiment 3

[0068] A concrete comprising the following components in parts by mass:

[0069] Portland cement 30kg; water 60kg; sand 30kg; stone 50kg; sulfamate superplasticizer 1.8kg; carboxymethyl cellulose 0.2kg; silane coupling agent 10kg.

[0070] In this embodiment, the viscosity of carboxymethyl cellulose is 6000 mPa.s.

[0071] In this embodiment, N-(2-aminoethyl)-3-aminopropyltrimethoxysilane is used as the silane coupling agent.

[0072] Concrete is prepared as follows:

[0073] (1) Add 30kg of sand and 50kg of stone to the sand and gravel mixer at room temperature, and stir at a speed of 200r / min. After stirring evenly, aggregates are obtained;

[0074] (2) Add Portland cement 30kg while stirring, after stirring evenly, obtain the premix;

[0075] (3) Put the uniform premix in step (2) into the concrete mixer. Under normal temperature, stir at a speed of 200r / min. While stirring, add 60kg of water and sulfamate-based high-efficiency water reducer 1.8 kg, 0.2 kg of carboxymet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com