Glycyrrhiza glabra extract and preparation method and applications thereof

A technology for extracting and licorice glabra, applied in the field of licorice glabra extract and preparation thereof, can solve the problems of less comprehensive utilization, large safety risks, discount of drug efficacy, etc., and achieve comprehensive utilization of resources and product components. Clear, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

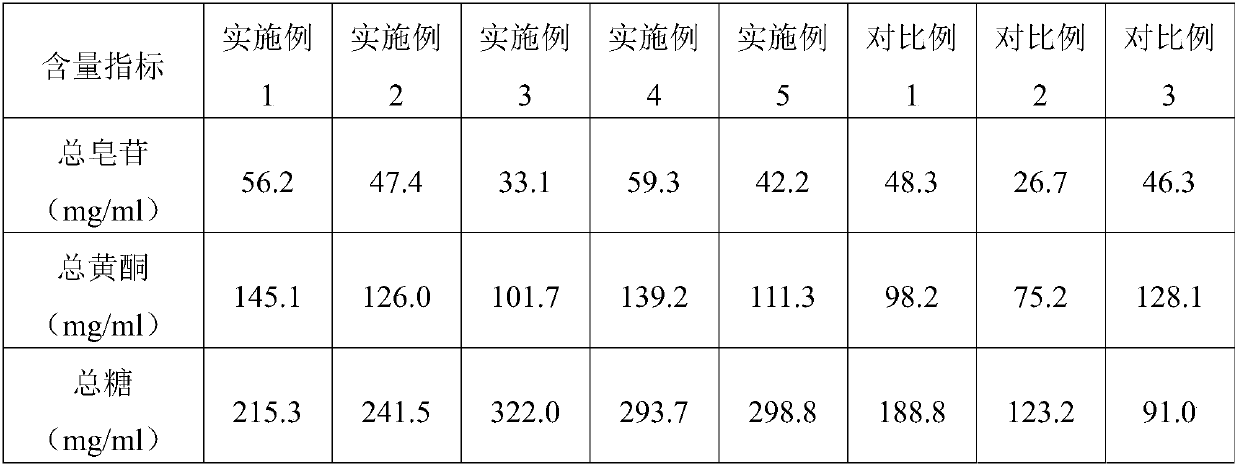

Embodiment 1

[0060] A kind of licorice glabra extract is prepared by the following method:

[0061] The roots and rhizomes of 10kg of fresh licorice (Glycyrrhiza glabra L.) were pulverized with a JMW-200 horizontal colloid mill (Shanghai Liangyi Pump Industry) (the fixed rotation distance was 0.3mm, and the rotating speed was 2900rpm) to obtain a homogeneous pulverized product. Add 200kg of butanediol to the homogenized pulverized matter, extract with an ultrasonic extractor at 60°C and an ultrasonic frequency of 20KHz for 60 minutes, extract once in total, and then pass the obtained ultrasonic extract through a three-legged centrifuge at 4000 rpm Centrifuge to remove medicinal residues, use 500nm ceramic membrane separation (continuous membrane separation) to remove macromolecular substances such as pectin resin, take the membrane clear liquid, and then concentrate it to a relative density of 1.12 (25°C) with an ultrafiltration membrane with a molecular weight cut-off of 3000Da ) to obtai...

Embodiment 2

[0063] A kind of licorice glabra extract is prepared by the following method:

[0064] The roots and rhizomes of 10kg of fresh licorice (Glycyrrhiza glabra L.) were pulverized with a JMW-200 horizontal colloid mill (the fixed rotation distance was 0.1mm, and the rotation speed was 1500rpm) to obtain a homogeneous pulverized product; to the homogeneous pulverized product, add 300kg70% butanediol aqueous solution (W / W), extracted with an ultrasonic extractor at 40°C and an ultrasonic frequency of 30KHz for 90 minutes, extracted once in total, and then passed the obtained ultrasonic extraction solution through a 4000 rpm three-legged centrifuge Centrifuge to remove medicinal residues, use 800nm ceramic membrane to separate and remove macromolecular substances such as pectin resin, take the membrane clear liquid, and then concentrate it to a relative density of 1.13 (25°C) with an ultrafiltration membrane with a molecular weight cut-off of 5000Da to obtain Guangguo Licorice extr...

Embodiment 3

[0066] A kind of licorice glabra extract is prepared by the following method:

[0067] The root and rhizome of 10kg of fresh licorice glabra (Glycyrrhiza glabra L.) is pulverized with a JMW-200 horizontal colloid mill (fixed rotation distance is 0.2mm, rotating speed 2000rpm) to obtain a homogeneous pulverized product; to the homogeneous pulverized product, add 150kg30% butanediol aqueous solution (W / W), extracted with an ultrasonic extractor for 30 minutes at 50°C and an ultrasonic frequency of 60KHz, extracted once in total, and then passed the obtained ultrasonic extraction solution through a 6000 rpm three-legged centrifuge Centrifuge to remove medicinal residues, use a 1000nm ceramic membrane to separate and remove macromolecular substances such as pectin resin, take the supernatant, and then use ultrafiltration with a molecular weight cut-off of 10,000Da to concentrate to a relative density of 1.10 (25°C) to obtain Glycyrrhiza glabra extract thing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com