High-fiber energy slow-release miscellaneous cereal noodles and making method thereof

A high fiber and energy technology, applied in the field of food science, can solve the problem that the concept of sustained release is not widely cited, and achieve the effect of lowering blood sugar and blood lipids, slowing down the digestion rate, and inhibiting the rise of the blood sugar index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

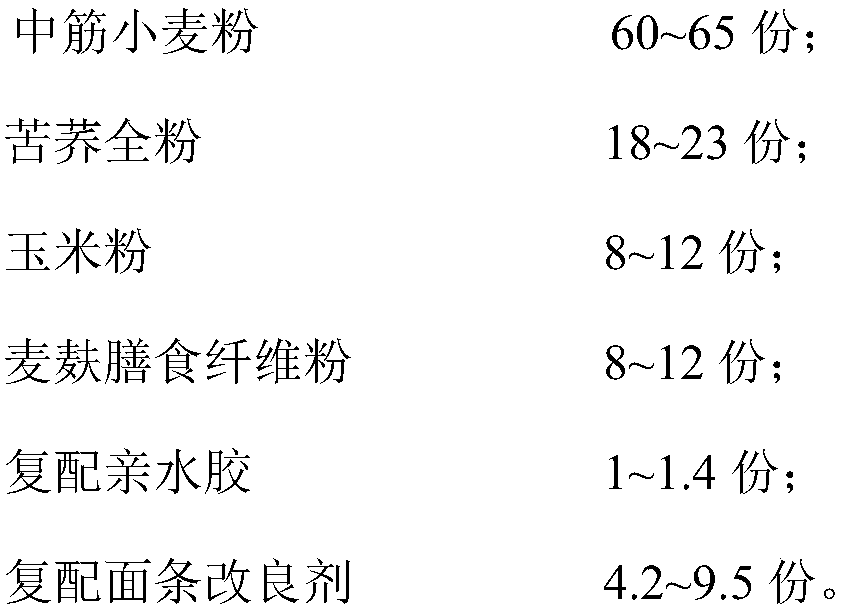

[0113] A high-fiber energy slow-release miscellaneous grain noodle, calculated in parts by weight, its raw materials include:

[0114]

[0115] The compound hydrophilic glue is formed by mixing konjac gum, xanthan gum and carrageenan according to the mass ratio of konjac gum: xanthan gum: carrageenan at 1:1:0.8. The compound noodle improver is formed by mixing common salt, gluten powder and sodium alginate in a mass ratio of 4:8:1, instant salt: gluten powder: sodium alginate.

[0116] The preparation method of described high-fiber energy slow-release miscellaneous cereal noodles is:

[0117] A. Ingredients:

[0118] Take medium-gluten wheat flour, tartary buckwheat whole powder, wheat bran dietary fiber powder, corn flour, compound noodle improver according to parts by weight, and fully mix;

[0119] B. Preparation of compound hydrocolloid:

[0120] According to the mass ratio of compound hydrophilic rubber powder and boiling water (100°C) of 1:2, add boiling water into...

Embodiment 2

[0134] A high-fiber energy slow-release miscellaneous grain noodle, calculated in parts by weight, its raw materials include:

[0135]

[0136] The compounded hydrophilic glue is: konjac gum, xanthan gum and carrageenan are mixed in a mass ratio of konjac gum: xanthan gum: carrageenan at 1:1:0.8;

[0137] The compound noodle improver is: salt, gluten powder and sodium alginate mixed by mass ratio instant salt: gluten powder: sodium alginate is 4:8:1;

[0138] The preparation method of described high-fiber energy slow-release miscellaneous cereal noodles is:

[0139] A. Ingredients

[0140] Take medium-gluten wheat flour, tartary buckwheat whole powder, wheat bran dietary fiber powder, corn flour, compound noodle improver according to parts by weight, and fully mix;

[0141] B. Preparation of compound hydrocolloid

[0142] According to the mass ratio of compound hydrophilic rubber powder and boiling water (100°C) of 1:2, add boiling water into the mixer, control the speed...

Embodiment 3

[0157] A high-fiber energy slow-release miscellaneous grain noodle, calculated in parts by weight, its raw materials include:

[0158]

[0159] The compounded hydrophilic glue is: konjac gum, xanthan gum and carrageenan are mixed in a mass ratio of konjac gum: xanthan gum: carrageenan at 1:1:0.8;

[0160] The compound noodle improver is: salt, gluten powder and sodium alginate mixed by mass ratio instant salt: gluten powder: sodium alginate is 4:8:1;

[0161] The preparation method of described high-fiber energy slow-release miscellaneous cereal noodles is:

[0162] A. Ingredients

[0163] Take medium-gluten wheat flour, tartary buckwheat whole powder, wheat bran dietary fiber powder, corn flour, compound noodle improver according to parts by weight, and fully mix;

[0164] B. Preparation of compound hydrocolloid

[0165] According to the mass ratio of compound hydrophilic rubber powder and boiling water (100°C) of 1:2, add boiling water into the mixer, control the speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com