Optimization method for charging strategy of lithium-ion batteries

A lithium-ion battery and charging strategy technology, which is applied in the direction of secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve problems such as low cost, long charging time, and adverse effects on battery life, so as to ensure cycle performance, Reduce charging time, improve the effect of design and production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Such as figure 1 as shown, figure 1 It is a flow chart of an optimization method for a lithium-ion battery charging strategy proposed by the present invention.

[0018] The optimization method of a lithium-ion battery charging strategy proposed by the present invention is realized through the following three stages:

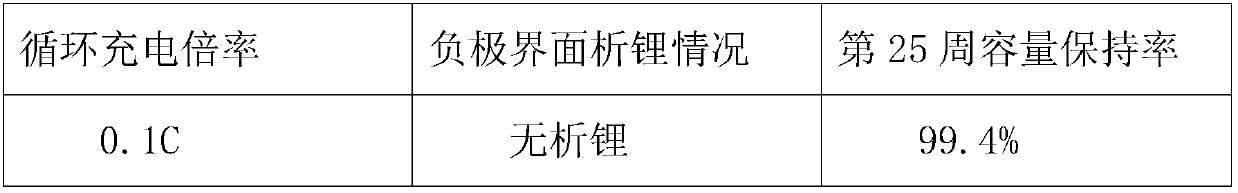

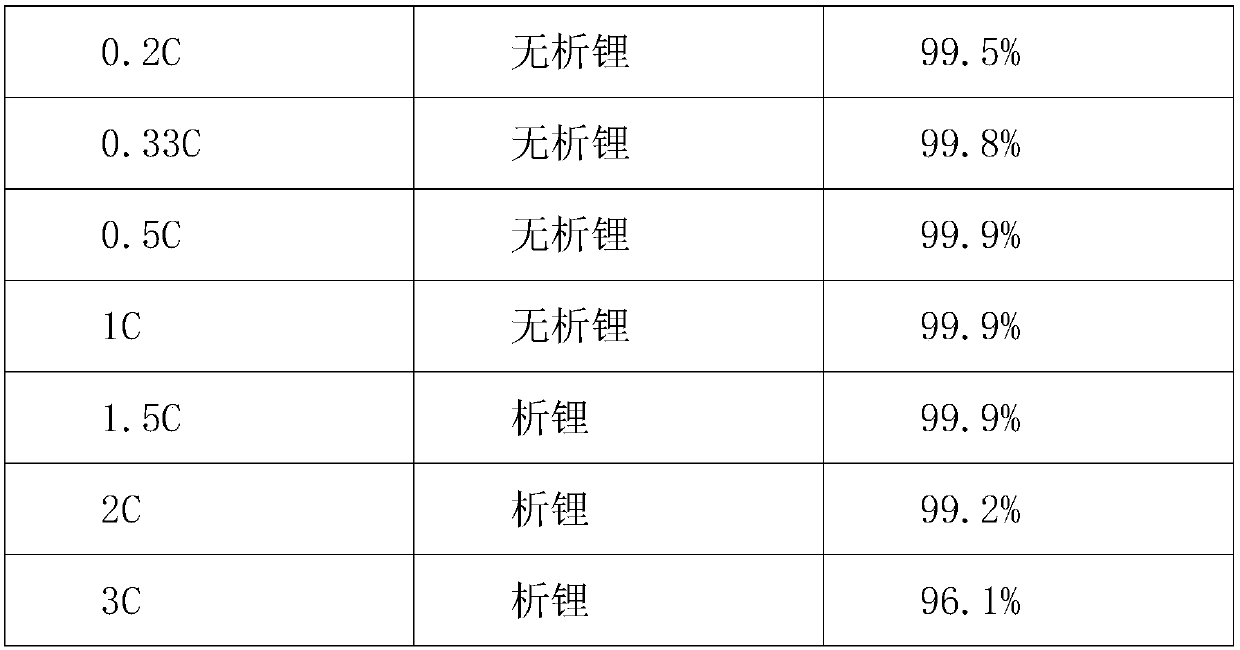

[0019] The first stage: the determination of the maximum allowable continuous charging rate C1 and lithium analysis charging rate C2 in the full SOC range (0%-100%).

[0020] (1) Choose a cylindrical lithium iron phosphate battery with a rated capacity of 14Ah and a working voltage range of 2.0-3.65V. Use laser welding copper tabs on the poles to measure whether the voltage, internal resistance, and thickness of the battery meet the product specification range , to select qualified batteries within the specification range;

[0021] (2) Select the battery to discharge to 2.0V at 1C, so that the battery is in an empty state, and use different batteries at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com