Negative pole piece of lithium ion battery, preparation method of negative plate and lithium ion battery

A lithium-ion battery, negative electrode technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as electrode cracks, affecting the electronic path and conductivity of the electrode, and achieve long cycle life and excellent capacity retention. rate and rate performance, and the effect of improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The embodiment of the present invention also provides a method for preparing a negative electrode sheet of a lithium ion battery, comprising the following steps:

[0051] S10. Obtain copper foil as the negative electrode collector;

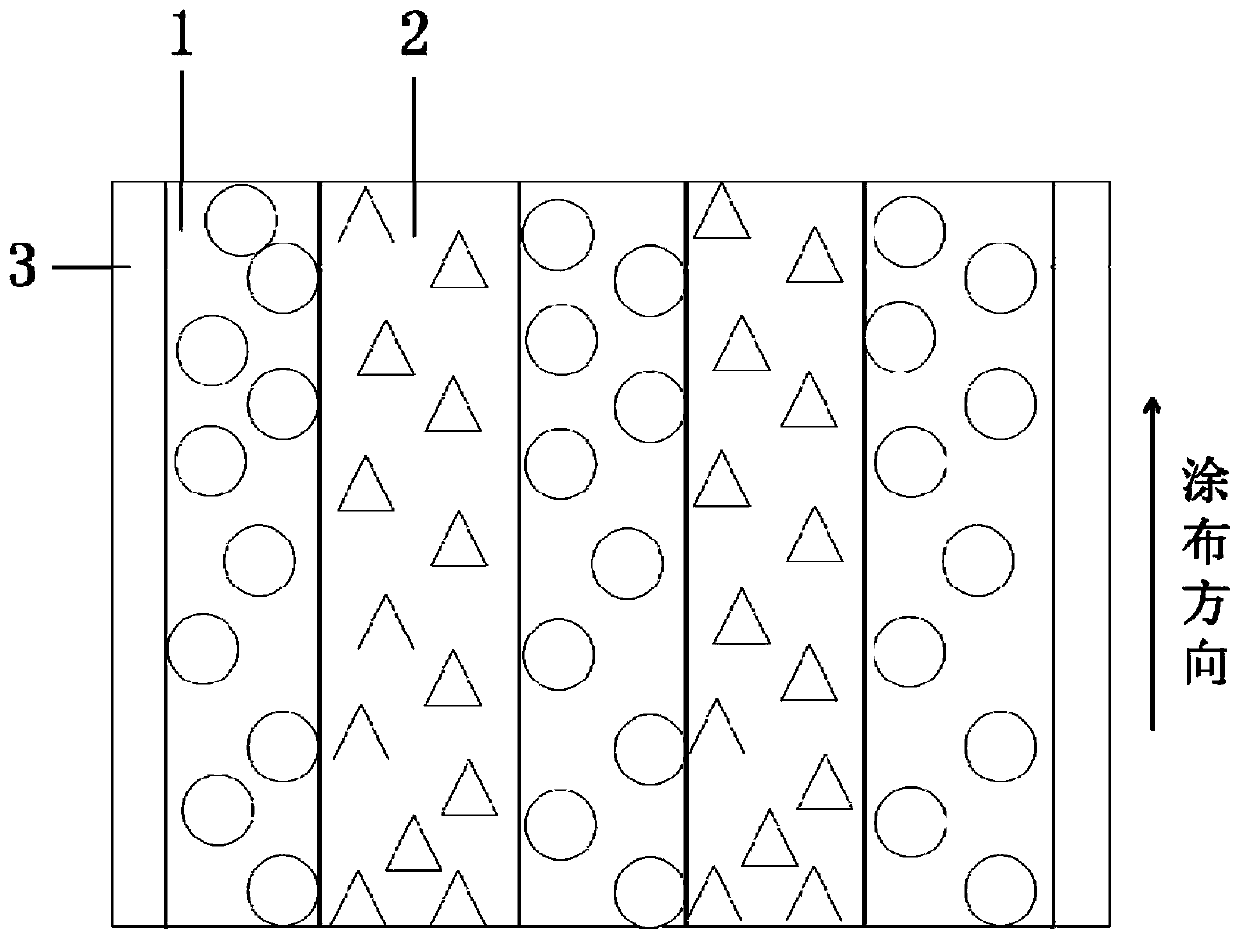

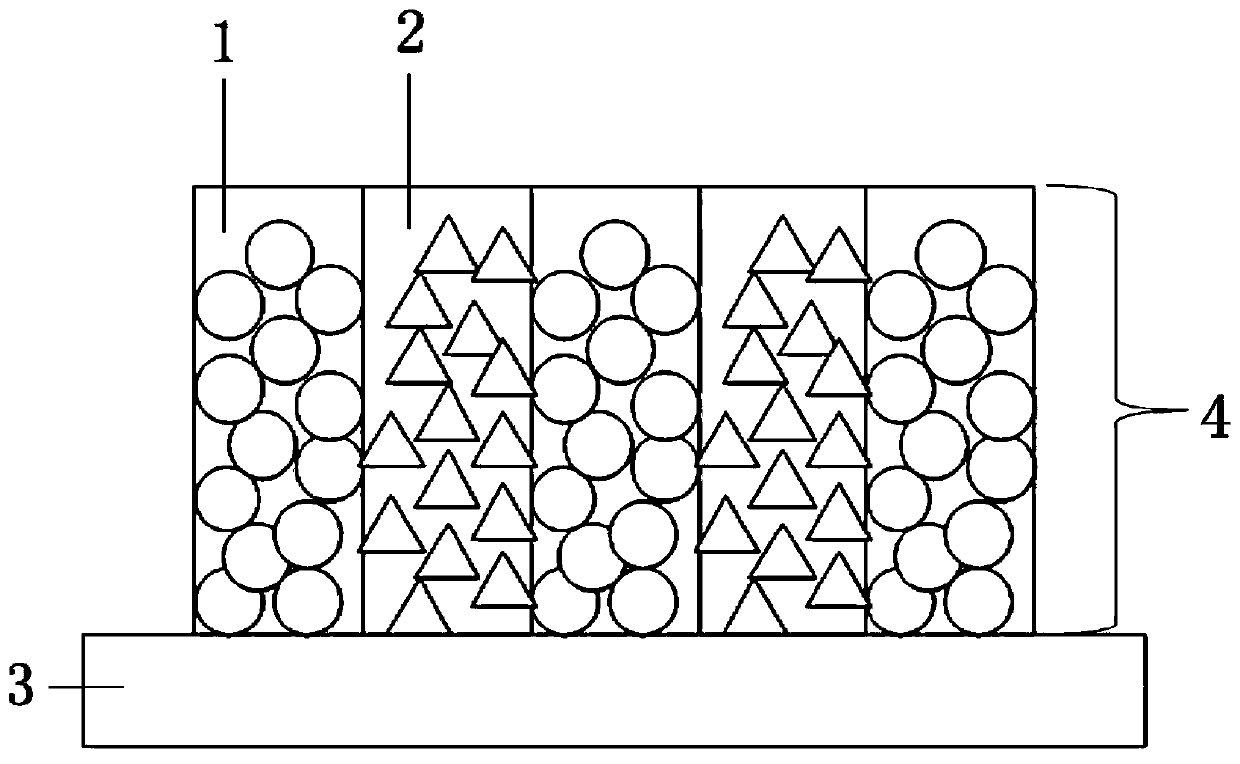

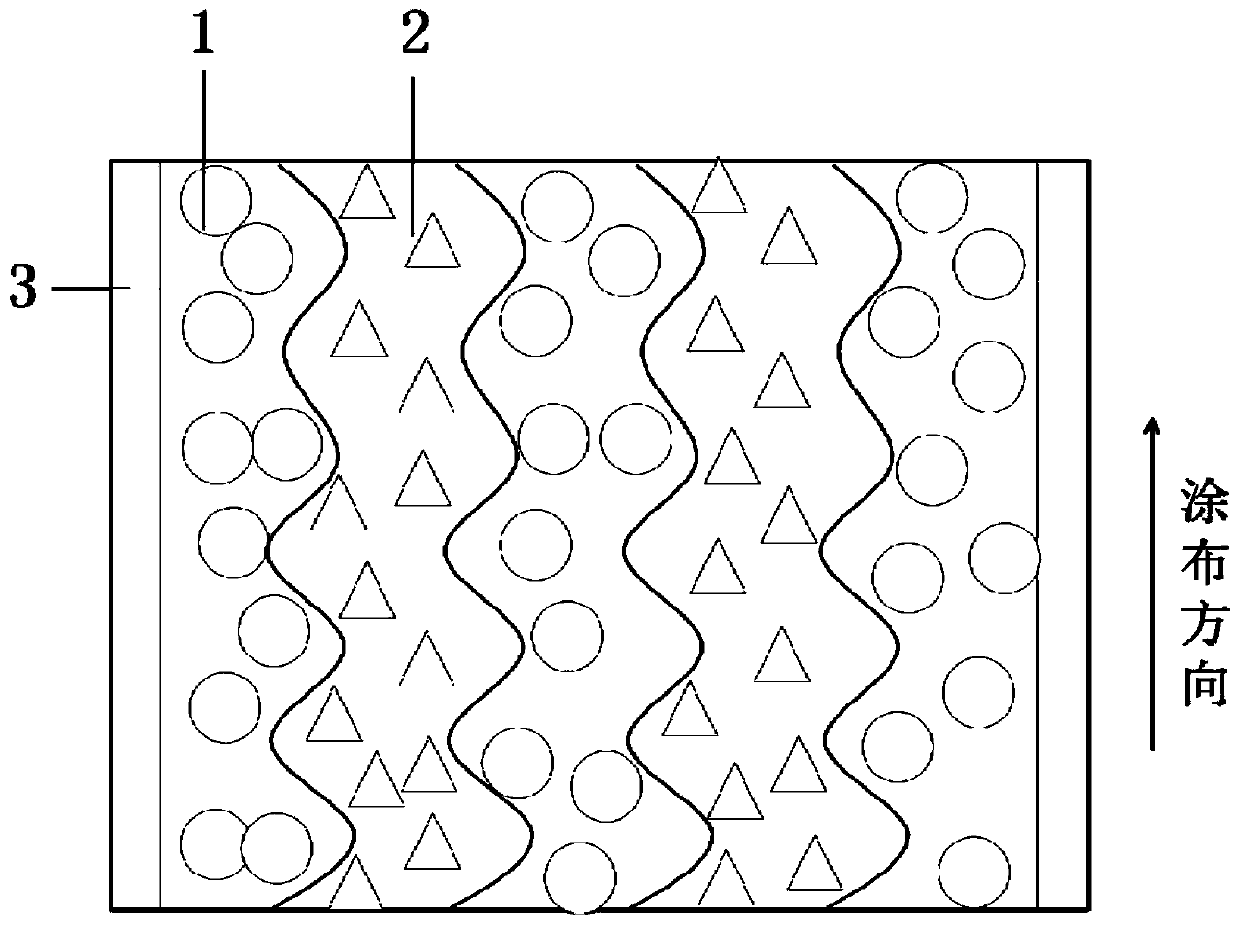

[0052] S20. Acquiring silicon-based materials and carbon-based materials, depositing the silicon-based materials and the carbon-based materials on the copper foil, so that alternately distributed strips of carbon-based materials are formed on the copper foil from left to right 1 and a silicon-based material strip 2, the carbon-based material strip 1 and the silicon-based material strip 2 are in conductive contact with each other to obtain a deposition product;

[0053] S30. Drying and rolling the deposited product to obtain a lithium-ion battery negative electrode sheet.

[0054] The preparation method of the lithium-ion battery negative plate provided by the embodiment of the present invention, after obtaining the copper foil, silicon-bas...

Embodiment 1

[0064] A lithium ion battery comprising:

[0065] Negative electrode sheet: Alternately coated with 2 cm artificial graphite HSG carbon-based material strips 1 and 5 cm silicon-oxygen composite SO450 silicon-based material strips on the copper foil from left to right in the transverse direction of the negative electrode sheet coating direction 2. The material coating thickness is 80 microns. The contact surface of the carbon-based material strip 1 and the silicon-based material strip 2 is plane;

[0066] Assemble the negative electrode sheet, the positive electrode sheet and the diaphragm to make a 053048 type pouch battery.

Embodiment 2

[0068] A lithium ion battery comprising:

[0069] Negative electrode sheet: Alternately coated with 5 cm artificial graphite HSG carbon-based material strip 1 and 5 cm silicon-oxygen composite material SO450 silicon-based material strip on the copper foil from left to right in the transverse direction of the coating direction of the negative electrode sheet 2. The material coating thickness is 80 microns. The contact surface of the carbon-based material strip 1 and the silicon-based material strip 2 is plane.

[0070] A 053048 type pouch battery was assembled by assembling the same positive electrode sheet and diaphragm as the negative electrode sheet in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com