Probe structure capable of being used for intertubular automatic video inspection of steam generator

A steam generator and video technology, which is applied in the directions of instruments, scientific instruments, and the indication of the working conditions of boilers, can solve the problems of high requirements for operating skills, uneven video inspection quality, and increased collective dose of personnel, and achieves a solid structure. , compact structure, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

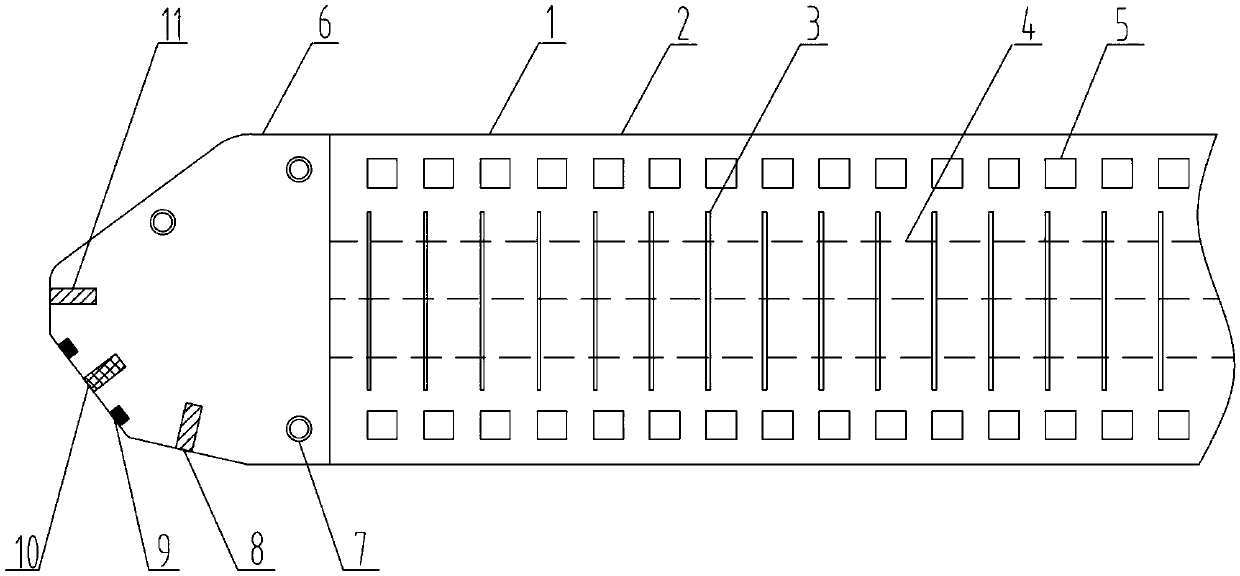

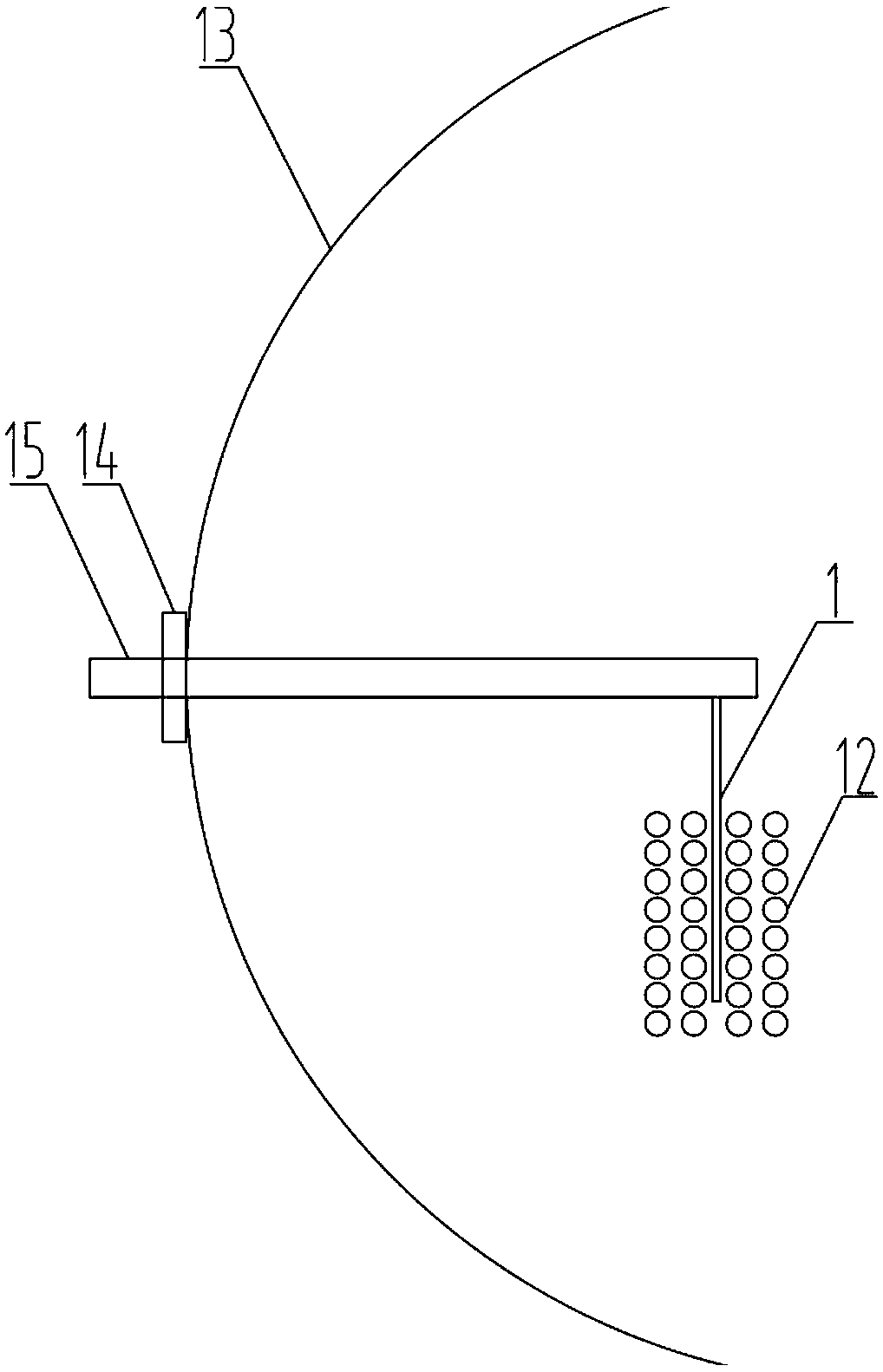

[0033] Such as figure 1 As shown, a probe structure that can be used for automatic video inspection between steam generator tubes includes two parts: the probe end 6 and the probe steel strip 2 . The probe end 6 is fixed on the left end of the probe steel band 2, and is used for video inspection of the cleanliness of the inter-tube area of the heat transfer tube 12 inside the steam generator 13, and at the same time grasps the foreign matter found. The probe steel belt is used to transport the probe end 6 to the video inspection position, and protect the cables connected to the probe end 6 .

[0034] The probe end 6 includes a probe end housing, a fastening screw 7 , a downward lens 8 , an LED light source 9 , a foreign object grasping channel 10 and a forward lens 11 . The downward lens 8, the LED light source 9, the foreign matter grasping channel 10 and the forward lens 11 are arranged inside the probe end shell. The left end of the probe end shell is provided with a pl...

Embodiment 2

[0043] Such as figure 1 As shown, a probe structure that can be used for automatic video inspection between steam generator tubes includes two parts: the probe end 6 and the probe steel strip 2 . The probe end 6 is fixed on the left end of the probe steel band 2, and is used for video inspection of the cleanliness of the inter-tube area of the heat transfer tube 12 inside the steam generator 13, and at the same time grasps the foreign matter found. The probe steel belt is used to transport the probe end 6 to the video inspection position, and protect the cables connected to the probe end 6 .

[0044] The probe end 6 includes a probe end housing, a fastening screw 7 , a downward lens 8 , an LED light source 9 , a foreign object grasping channel 10 and a forward lens 11 . The downward lens 8, the LED light source 9, the foreign matter grasping channel 10 and the forward lens 11 are arranged inside the probe end shell. The left end of the probe end shell is provided with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com