Retrieving method for low-level waste in waste pit

A waste pit and waste technology, applied in radioactive purification, nuclear engineering, etc., can solve the problems of being unable to freely grasp waste pits and low efficiency of waste retrieval, and achieve the effects of preventing collisions, prolonging the use cycle, and improving retrieval efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The invention discloses a method for replaying low-level waste in pits. The power manipulator is used to grab the waste in the mouth of the waste pit to the orthographic projection area below the mouth of the waste pit, and then use the electric gripper to grab the waste in the orthographic projection area below the mouth of the waste pit. Waste is grabbed outside the waste pit and packed into waste bins or transfer containers.

[0051] This method is applicable to the retrieval of all types of low-level waste from pits.

Embodiment 2

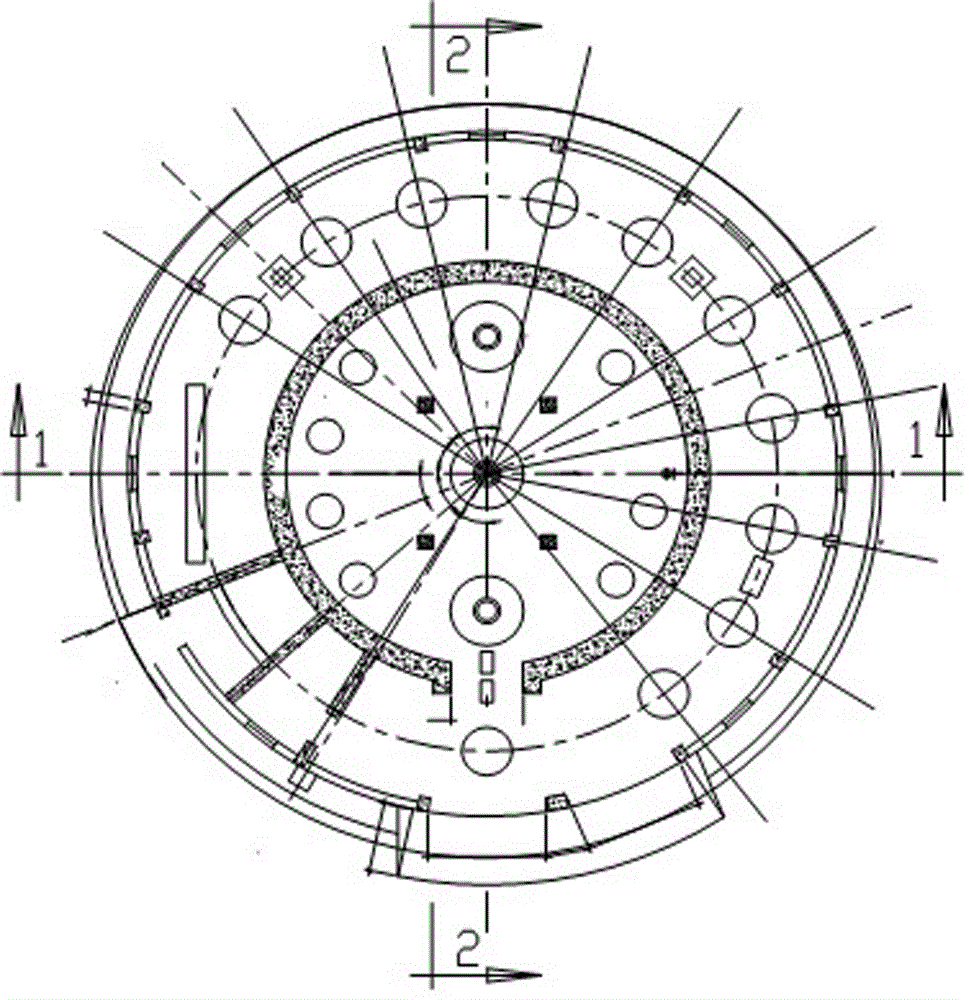

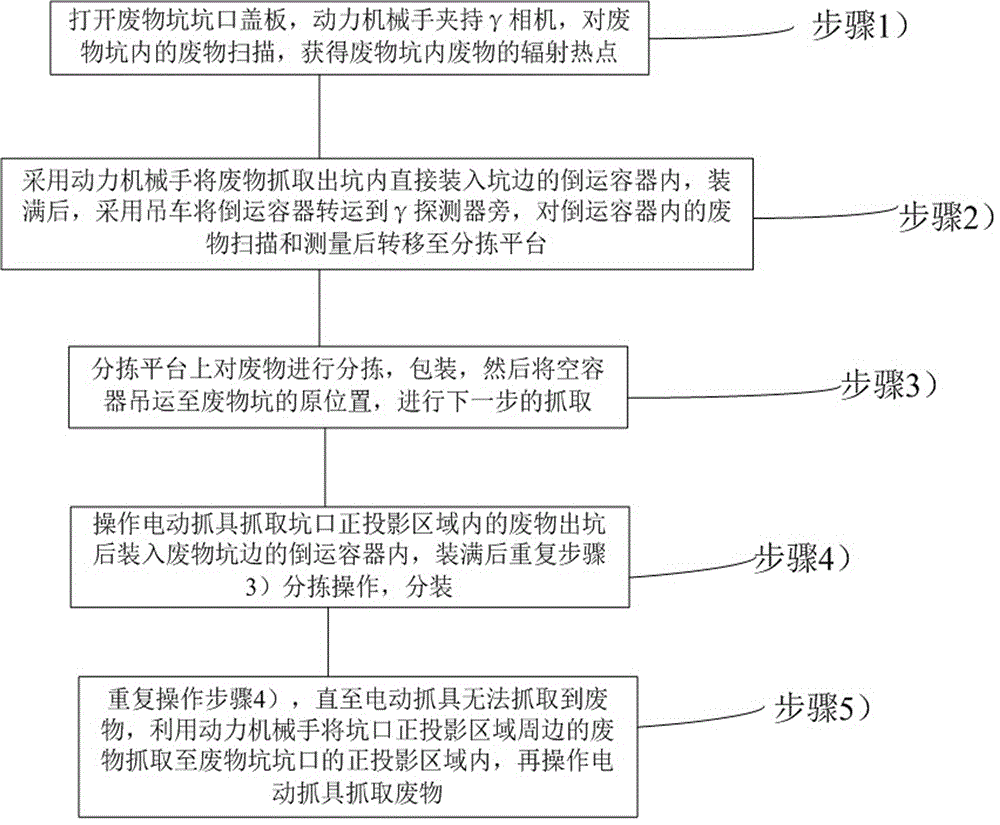

[0053] The invention discloses a method for replaying low-level radioactive waste in pits, aiming at figure 1 The shown waste pit, its retrieving method comprises the following operating steps, as figure 2 as shown,

[0054] Step 1): Open the pit mouth cover of the waste pit, the powered manipulator holds the γ camera, scans the waste in the waste pit, obtains the radiation hot spots of the waste in the waste pit, and determines the grabbing step according to the number and area of the radiation hot spots;

[0055] Step 2): Use a power manipulator to grab the waste with a radiation level greater than 10mSv / h out of the pit and put it directly into the dump container beside the pit. After it is full, use a crane to transfer the dump container to the gamma detector. After the waste is scanned and measured, it is transferred to the sorting platform, where the crane can be a 3t crane for lifting the dumped container, and the crane can also be replaced by a powered manipulator ...

Embodiment 3

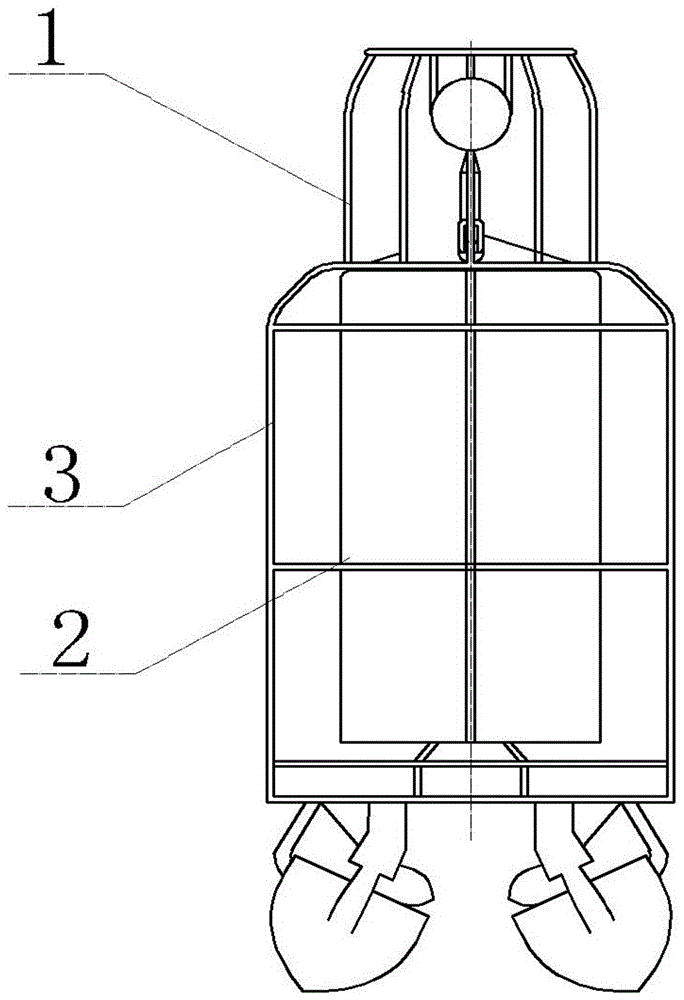

[0072] On the basis of the above examples, if image 3 As shown, the electric grab is defined as an electro-hydraulic four-lobe grab. The electro-hydraulic four-lobe grab includes a grab body 3, and a guide cap 1 is provided around the opening end of the grab body 3. The guide cap 1 It is formed by connecting two circular steel bars with multiple arc steel bars around the opening end of the grab body 3, the diameter of the circular steel bar at the upper end of the two circular steel bars is smaller than that of the circular steel bar at the lower end. The diameter of the bar.

[0073] Preferably, a guide angle is provided at the connecting end of the circular steel bar at the upper end and the arc-shaped steel bar, and the angle range of the guide angle is 110-160°.

[0074] Preferably, the main body of the grab fuselage 3 is provided with a protective device 2 around, and the protective device 2 is formed by interweaving a plurality of longitudinally arranged circular steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com