Rice drying and turning process for improving whole rice rate and production equipment thereof

A technology of milling rice rate and production equipment, which is applied in the field of binning technology, can solve the problems of uncontrolled rice core temperature, low rice milling rate, and poor taste, so as to achieve precise control of moisture content, improve economic benefits, The effect of reducing the number of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

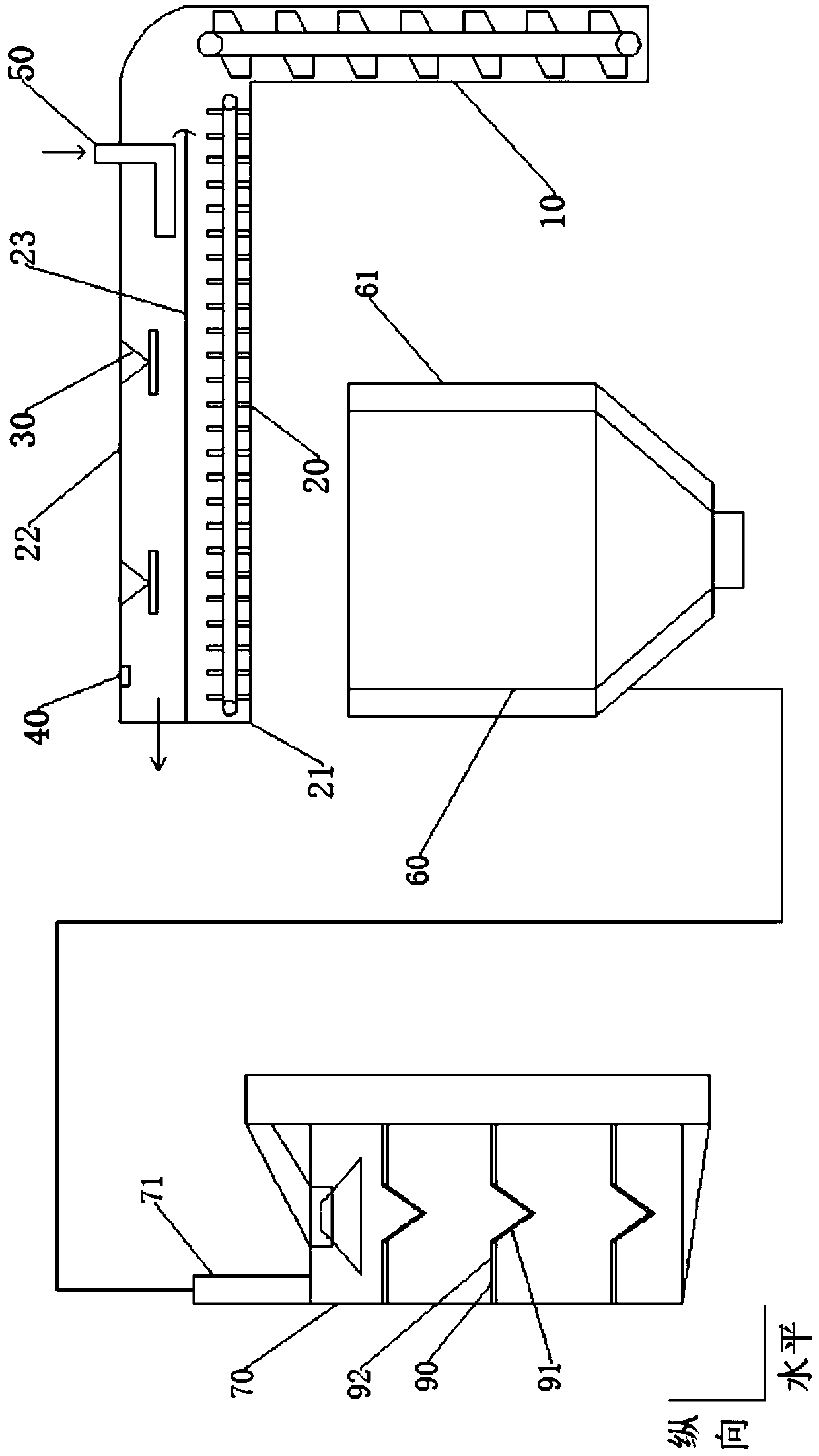

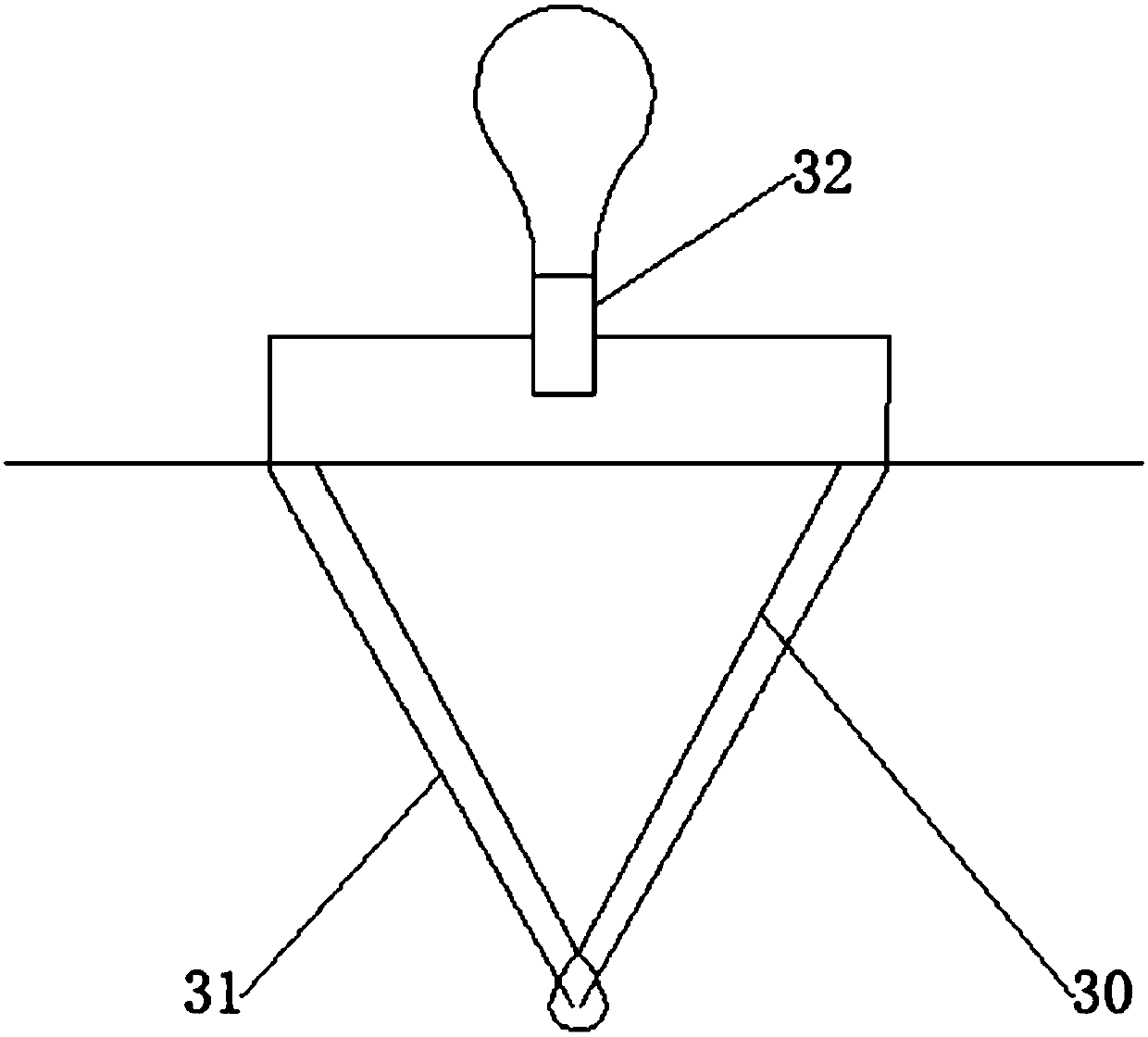

[0031] The invention will be described in detail below in conjunction with the accompanying drawings.

[0032] A drying and binning process for increasing the rate of polished rice, comprising a drying and binning process, characterized in that the specific steps are as follows:

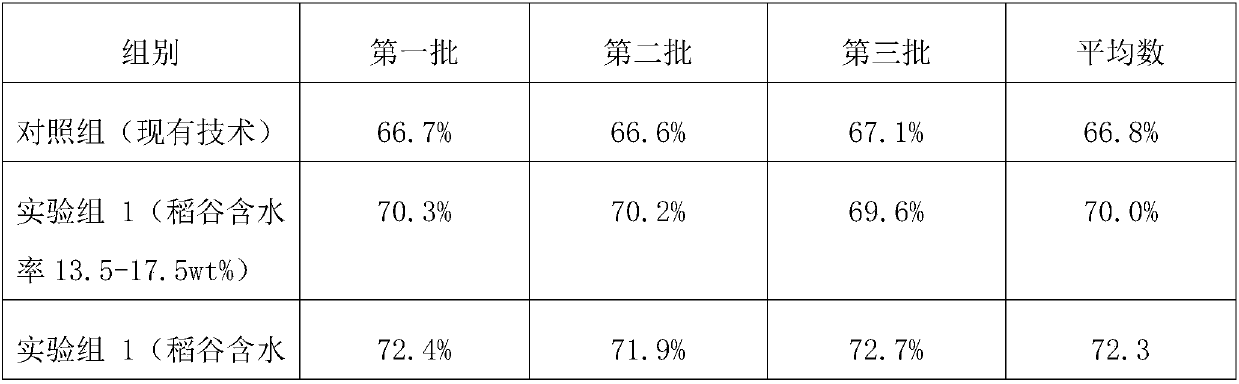

[0033] 4) Drying process: the rice is dried in hot air, wherein the temperature of the rice is maintained at 31-35° C., and dried until the moisture content of the rice drops to 13.5-16.5 wt %;

[0034] 5) Stuffed grain process: the dried rice is transported into the granary for sealed storage for 48 hours;

[0035] 6) Overturning process: the rice in the granary is unloaded, and then re-transported into the granary.

[0036] The purpose of stuffy grain is mainly to allow the water in each area to flow naturally in the air, so that the chaff and the surface of the rice can absorb a small amount of water, improve the toughness of the rice, and then increase its rice polishing rate.

[0037] There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com