Shield tunneling machine propelling system connected with single-piston-rod symmetric hydraulic oil cylinders in series

A hydraulic cylinder and propulsion system technology, applied in the direction of fluid pressure actuation system safety, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of affecting equipment life, wasting energy, throttling loss, etc., and achieve energy loss Small, increased flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

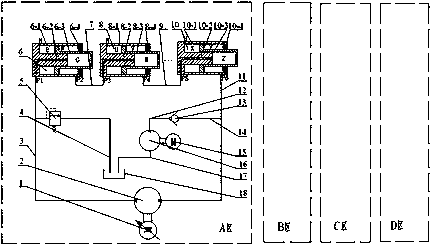

[0013] Attached below figure 1 And embodiment further illustrate the present invention.

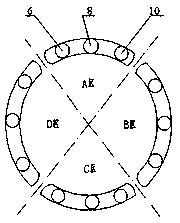

[0014] Such as figure 1 As shown, the present invention includes several partition propulsion systems with the same structure, and each quantitative pump provides power as an independent oil source of the corresponding partition propulsion system, and the hydraulic circuit of each partition propulsion system is mutually connected with the hydraulic circuits of other partition propulsion systems. Independent hydraulic circuit; each partition propulsion system includes servo motor 1, quantitative pump 2, safety valve 5, first hydraulic cylinder 6, second hydraulic cylinder 8, third hydraulic cylinder 10, check valve 13, charge pump 15, Composed of motor 16, etc.; the output shaft of servo motor 1 is rigidly connected to the input shaft of quantitative pump 2, and the oil port at the left end of quantitative pump 2 is respectively connected to the oil inlet at the left end of the first hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com