Method of using locally corrugated thin-wall steel pipes for preparing assembled concrete shear wall

A technology of concrete shear walls and thin-walled steel pipes, applied in walls, manufacturing tools, metal rolling, etc., can solve the problems of affecting structural performance, increasing costs, and difficulty in clearing the working status of double steel pipes, etc., to achieve the goal of improving structural performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

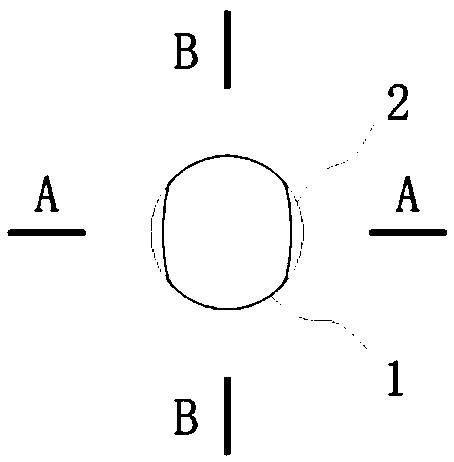

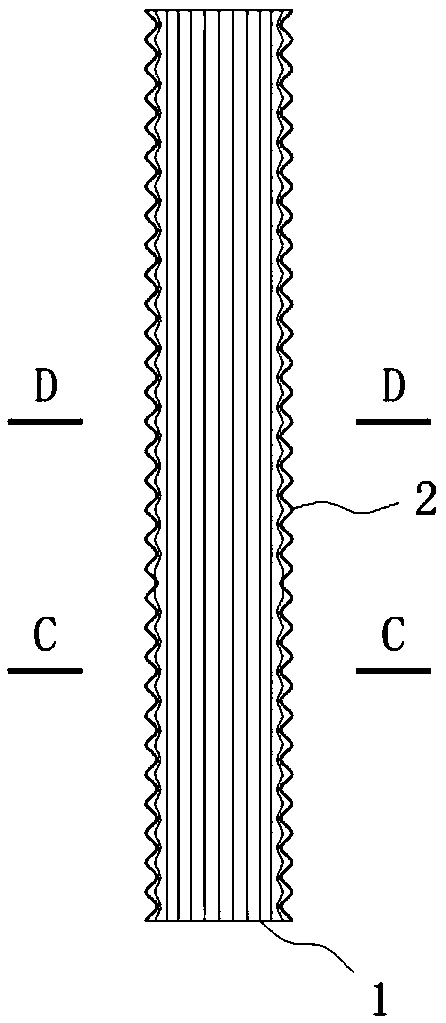

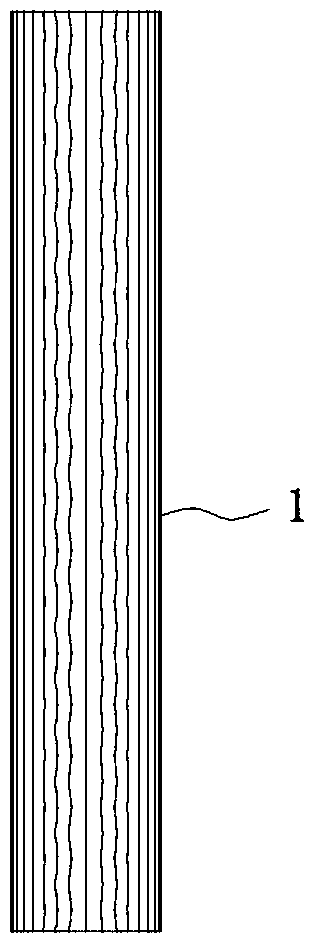

[0044] A method for preparing a prefabricated concrete shear wall using a local corrugated thin-walled steel pipe, wherein the local corrugated thin-walled steel pipe 1, such as Figure 1 to Figure 7 As shown, the steel pipe thickness of the local corrugated thin-walled steel pipe 1 is 0.2 mm to 3 mm, and the local corrugations 2 are provided at quarter circle positions on both sides of the symmetry, and the local corrugations 2 are concave or convex corrugations, and The pitch and height of each corrugation are 3mm-30mm.

[0045] like Figure 8 ~ Figure 10 As shown, the prefabricated concrete hollow wall panel 3 is provided with vertical hollow holes, and when the prefabricated concrete shear wall is prefabricated, the local corrugated thin-walled steel pipe 1 is used to prepare the precast concrete shear wall panel with hollow holes;

[0046] like Figure 11 and Figure 12 As shown, the post-cast concrete 4 is the concrete poured into the hollow hole of the precast concre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com