Prefabricated concrete shear wall based on multi-purpose thin-walled steel pipe and its construction method

A technology for concrete shear walls and thin-walled steel pipes, which is applied in building structures, walls, buildings, etc., can solve the problems of difficulty in clearing the working state performance of double steel pipes, difficult hole-forming procedures, and uncertain quality, and achieves improved prefabrication. The effect of production efficiency, efficient construction and convenient prefabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

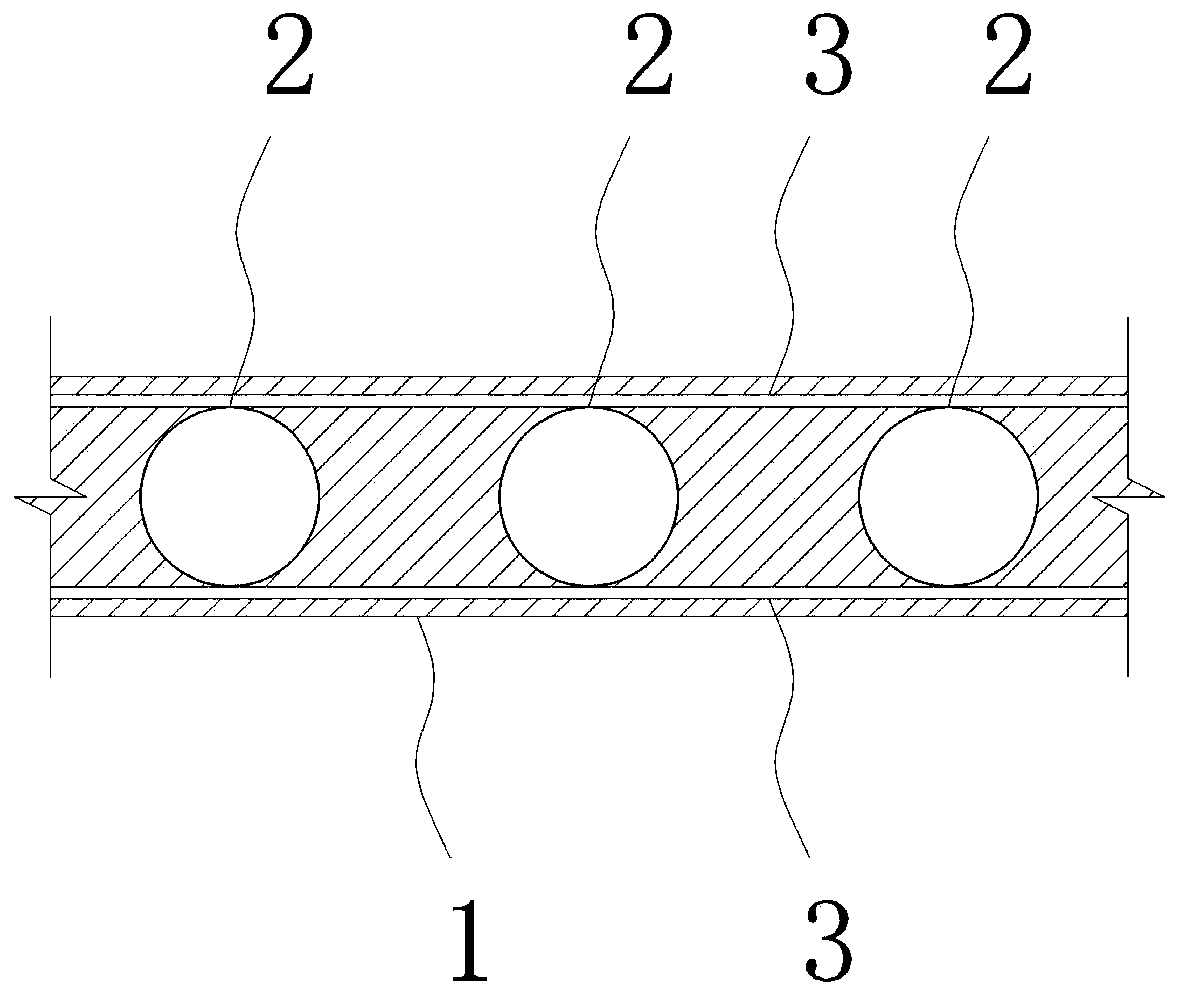

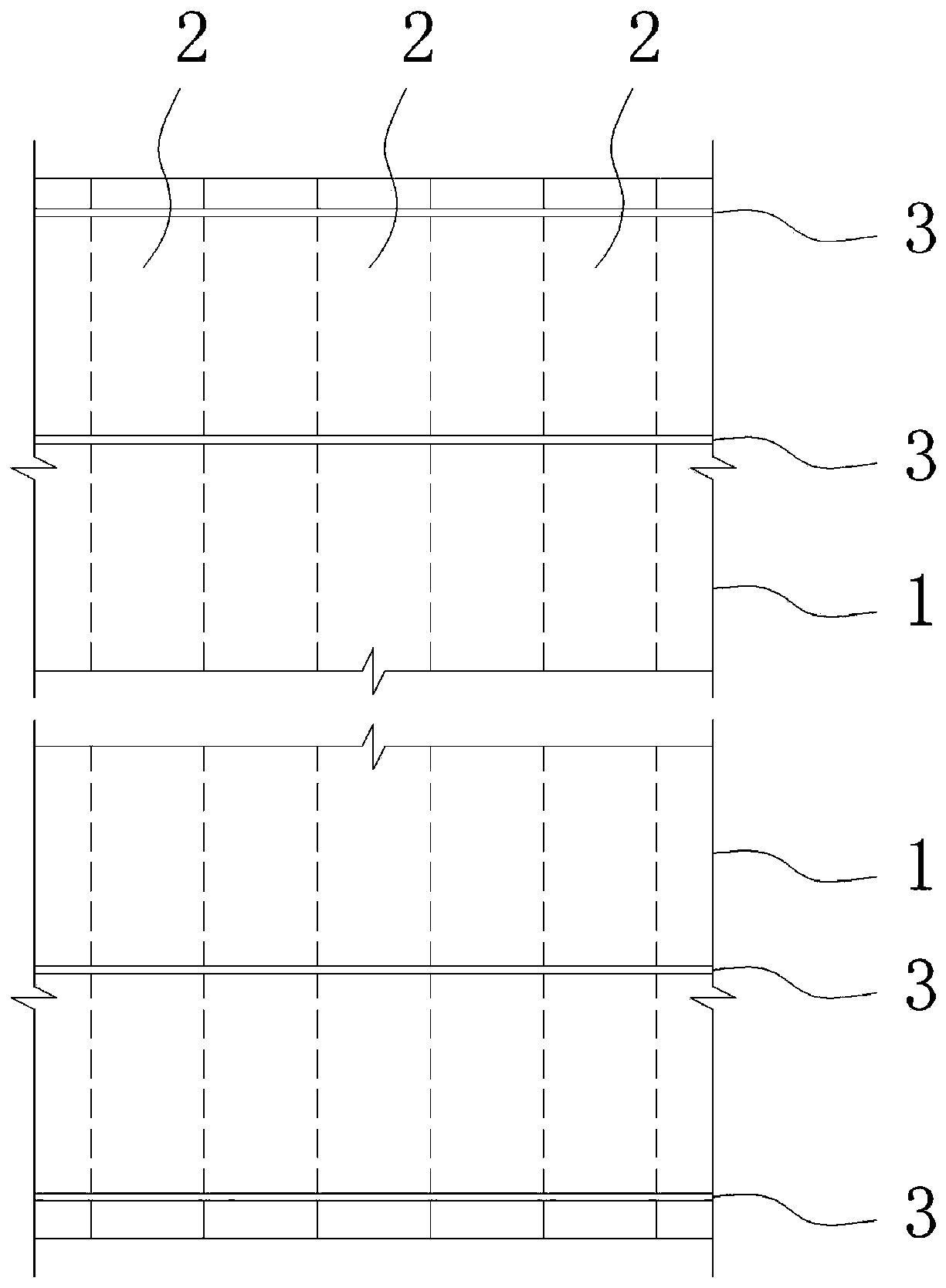

[0087] Embodiment one, such as Figure 1 to Figure 11 As shown, the construction of the prefabricated concrete shear wall based on multi-purpose thin-walled steel pipes:

[0088] Step 1. Preparation of precast concrete hollow wall panels 1

[0089] Prepare the precast concrete hollow wall panel 1 by using a flat mold, clean the table formwork, arrange more than two horizontally distributed steel bars 3 for the shear wall on the table formwork according to the design requirements, insert thin-walled steel pipes 2, support the side formwork, and fix the thin-walled steel pipes 2, Bind and fix the horizontally distributed steel bars 3 of the shear wall, arrange the pre-embedded pipelines, electrical junction boxes, connecting nuts and hooks, and then pour concrete, and after the curing strength reaches C20 or above, spray codes and stack them for later use;

[0090] Step 2. Prepare connecting steel bars

[0091] Prepare inverted U-shaped vertically distributed bottom ribs 4, th...

Embodiment 2

[0104] Embodiment two, such as Figure 12 to Figure 20 As shown, the edge members of the prefabricated concrete shear wall based on multi-purpose thin-walled steel pipes are constructed:

[0105] Step 1. Preparation of precast concrete hollow wall panels with edge elements 8

[0106] Prepare the prefabricated concrete hollow wall panel 8 with edge members using flat formwork, clean the table formwork, and arrange shear wall horizontally distributed reinforcement 3, edge member stirrups 9, edge member tie bars 10, edge members on the table formwork according to the design requirements Two or more longitudinal structural steel bars 11 are inserted into thin-walled steel pipes 2, side forms are supported, thin-walled steel pipes 2 are fixed, and horizontally distributed steel bars 3 are bound and fixed to the shear wall, edge member stirrups 9, edge member tie bars 10, edge member longitudinal Construct steel bars 11, arrange embedded pipelines, electrical junction boxes, connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com