Medical high-toughness cobalt-chromium alloy

A technology of cobalt-chromium alloy with high toughness, which is applied in medical science, pharmaceutical formulation, dentistry, etc., to meet the requirements of tensile and enamel hardness matching, simplify alloy composition, and improve toughness and elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

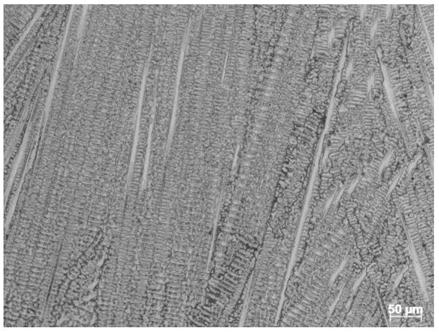

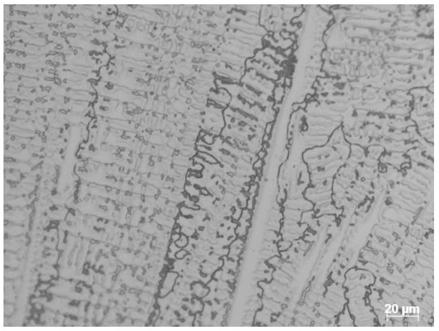

Image

Examples

Embodiment

[0024] Adopt the high-toughness cobalt-chromium alloy of chemical composition of the present invention, its chemical composition is as shown in Table 1 (embodiment 1, embodiment 2 and embodiment 3). For convenience of comparison, the cobalt-chromium alloy (comparative example) prepared by the prior art is also listed in Table 1 at the same time.

[0025] Table 1 Chemical Composition of Smelted Alloy (wt.%)

[0026]

co

Cr

Mo

Fe

Ti

mn

P

S

Example 1

60.3

28.9

7.8

2.0

0.5

0.5

0.010

0.010

Example 2

65.2

24.4

8.0

1.6

0.5

0.3

0.008

0.009

Example 3

66.0

26.8

5.0

1.3

0.8

0.1

0.009

0.008

comparative example

63.0

29.0

6.0

2.0

-

-

0.01

0.01

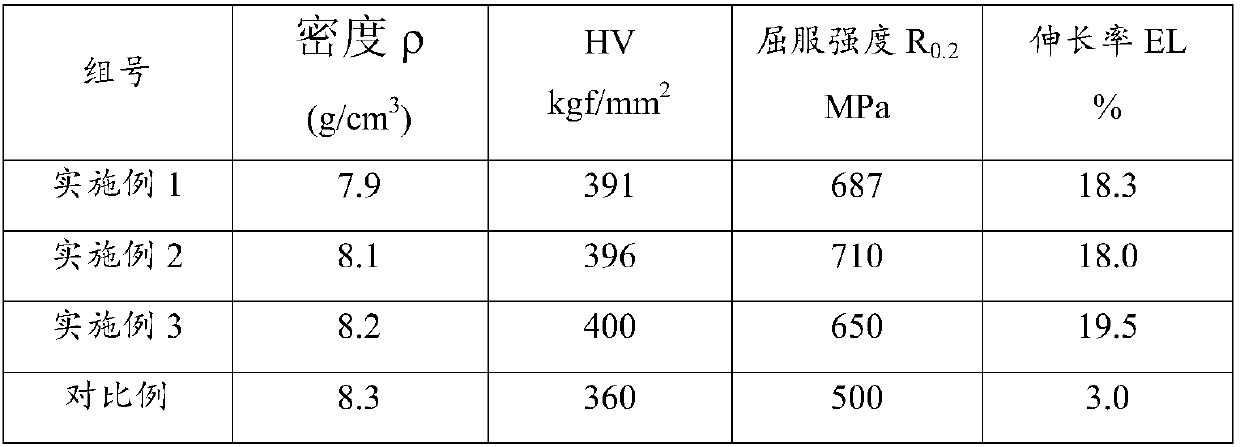

[0027] The mechanical properties of the alloys with the above components are shown in Table 2, indicating that changing the composition of the alloys can significantly improve the mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com