Preparation method of carbon nano tube enhanced zinc-aluminum alloy-base composite material

A technology of carbon nanotubes and zinc-aluminum alloys, which is applied in the field of preparation of zinc-aluminum-aluminum-based composite materials, can solve the problems of poor mechanical properties of carbon nanotube-reinforced zinc-aluminum-aluminum-based composite materials, uneven dispersion of carbon nanotubes, etc., and achieve composition The ratio is easy to control, the mechanical properties are improved, and the density is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

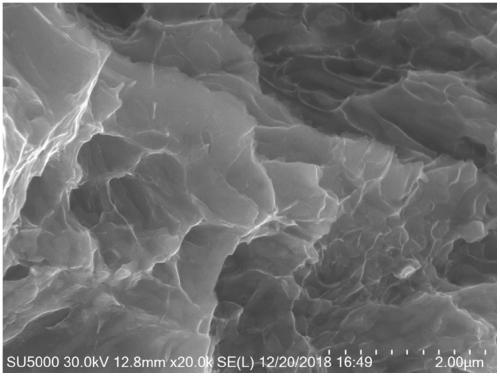

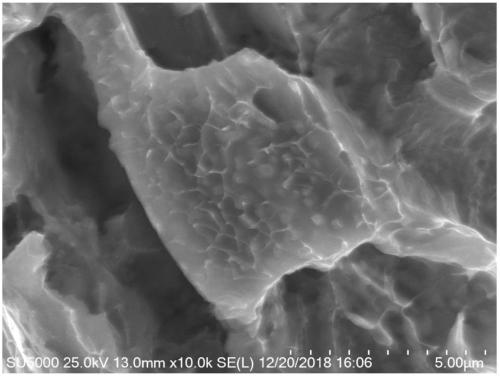

Image

Examples

specific Embodiment approach 1

[0027] Specific Embodiment 1: This embodiment is a method for preparing a carbon nanotube-reinforced zinc-aluminum alloy matrix composite material, which is completed in the following steps:

[0028] 1. Preparation of CNTs-Zn composite powder:

[0029] ①. Add carbon nanotubes and zinc powder to absolute ethanol, and then perform wet ball milling to obtain a mixture of carbon nanotubes, zinc powder and absolute ethanol;

[0030] ②. Vacuum drying the mixture of carbon nanotubes, zinc powder and absolute ethanol to obtain CNTs-Zn composite powder;

[0031] 2. Preparation of CNTs-Zn intermediate material:

[0032] ①. Use a hydraulic press to compress the CNTs-Zn composite powder to obtain a CNTs-Zn compact;

[0033] ②. Vacuum sintering the CNTs-Zn compact obtained in step 2 ① in a vacuum sintering furnace to obtain the CNTs-Zn intermediate material;

[0034] 3. Melting:

[0035] ①. First, preheat the melting furnace, then heat the melting furnace to 420°C-450°C, then add pure ...

specific Embodiment approach 2

[0046]Specific embodiment two: the difference between this embodiment and specific embodiment one is: the ball-to-material ratio of the wet ball mill described in step one 1. is (7~11):1, and the ball milling speed is 100r / min~300r / min , The ball milling time is 60min ~ 300min. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0047] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the temperature of the vacuum drying described in Step 1② is 55°C-78°C, and the time of vacuum drying is 120min-240min. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com