Motorcycle inner tube and preparation method thereof

A technology for motorcycles and inner tubes, applied in the field of tire manufacturing, can solve the problems of unspecified components and manufacturing processes of inner tubes, and achieve the effects of smooth product surface, strong energy absorption and impact resistance, and even and sufficient foaming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

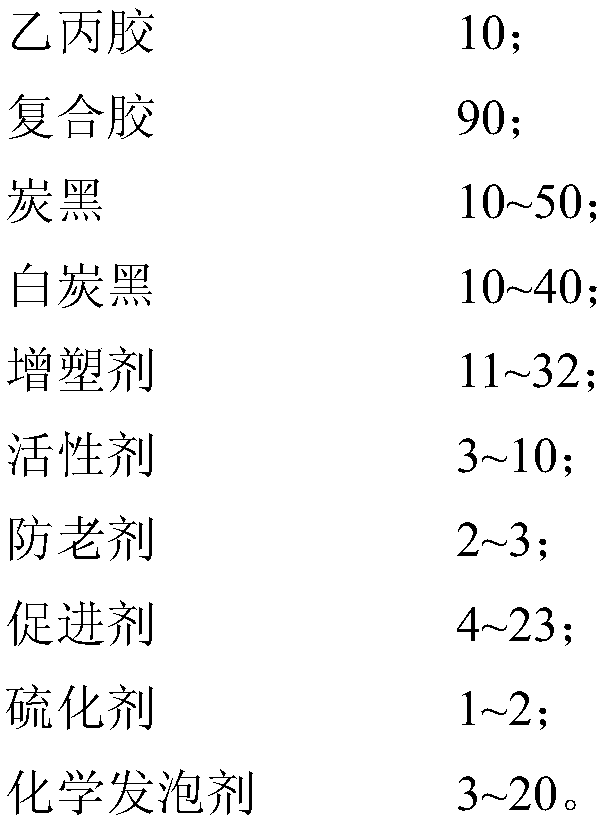

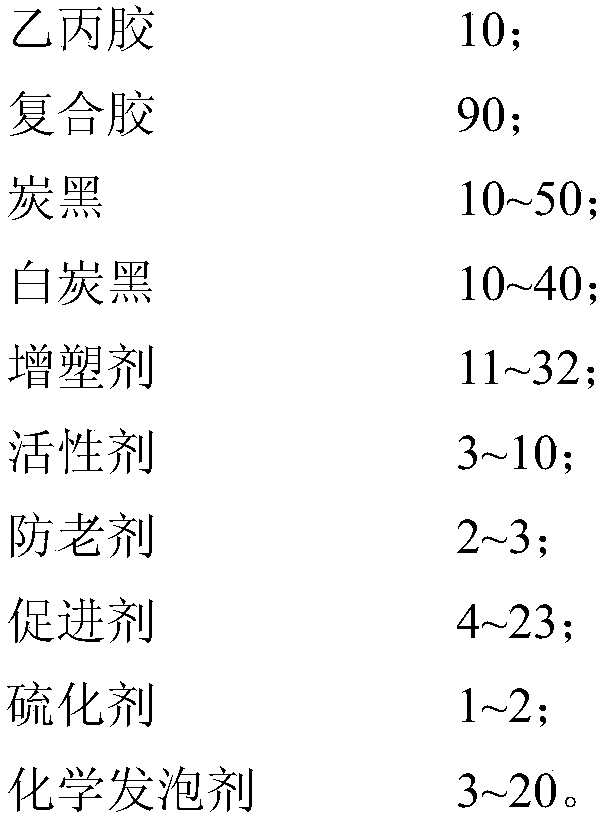

[0032] Such as figure 1 Shown, be the preferred embodiment one of motorcycle inner tube of the present invention and preparation method thereof, this motorcycle inner tube comprises the component of following parts by weight: ethylene propylene rubber 10 parts (a kind of aging resistance, weather resistance, temperature resistance, grease resistance 90 parts of neoprene (a kind of synthetic rubber with better impact resistance); 30 parts of carbon black (increasing the effect of foam resistance to tearing and impact reinforcement); 25 parts of white carbon black; 20 parts of paraffin oil 7 parts of nano zinc oxide; 2 parts of stearic acid; 2 parts of anti-aging agent; 2 parts of rubber accelerator DM; 1 part of sulfur; 10 parts of chemical foaming agent; 10 parts of urea grease.

[0033] The preparation method of inner tube comprises the steps:

[0034] 1. For ingredients, use the existing weighing tool electronic scale to weigh each component for backup, and the weighing err...

Embodiment 2

[0044] This embodiment is a preferred embodiment two of motorcycle inner tube and preparation method thereof, and the motorcycle inner tube comprises the following components in parts by weight: 10 parts of ethylene-propylene rubber; 90 parts of low-density polyethylene; 10 parts of carbon black; 40 parts of white carbon black 10 parts of paraffin oil; 3 parts of nano zinc oxide; 1.5 parts of stearic acid; 2.5 parts of antioxidant; 1 part of rubber accelerator DM; 1.5 parts of sulfur; 3 parts of chemical foaming agent; 3 parts of urea grease.

[0045] The preparation method of inner tube comprises the steps:

[0046] 1. For ingredients, use the existing weighing tool electronic scale to weigh each component for backup, and the weighing error is less than 0.5%;

[0047] 2. Masticating, mixing ethylene-propylene rubber and low-density polyethylene to obtain mixed rubber, the plasticizing temperature is 80 ° C, and the time is 10 minutes;

[0048] 3. Mixing, add carbon black, wh...

Embodiment 3

[0056] This embodiment is a preferred embodiment three of a motorcycle inner tube and its preparation method. The motorcycle inner tube includes the following components in parts by weight: 10 parts of ethylene propylene rubber; 90 parts of solution polystyrene butadiene rubber; 50 parts of carbon black; white carbon black 10 parts; 30 parts of paraffin oil; 10 parts of nano zinc oxide; 1 part of stearic acid; 3 parts of anti-aging agent; 3 parts of rubber accelerator DM; 2 parts of sulfur; 20 parts of chemical foaming agent; 20 parts of urea grease.

[0057] The preparation method of inner tube comprises the steps:

[0058] 1. For ingredients, use the existing weighing tool electronic scale to weigh each component for backup, and the weighing error is less than 0.5%;

[0059] 2. Masticating, mixing ethylene-propylene rubber and low-density polyethylene to obtain mixed rubber, the plasticizing temperature is 150 ° C, and the time is 30 minutes;

[0060] 3. Mixing, add carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com