A kind of secondary aminosilane coupling agent and preparation method thereof

The technology of a secondary amino silane coupling agent and a terminal primary amino silane coupling agent is applied in the field of organic synthesis and can solve the problems of yellowing of silane-modified polyether/polyurethane polymers, difficult control of the reaction process and high activity of primary hydrogen atoms. , to achieve the effect of easy process control, simple and easy preparation method, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

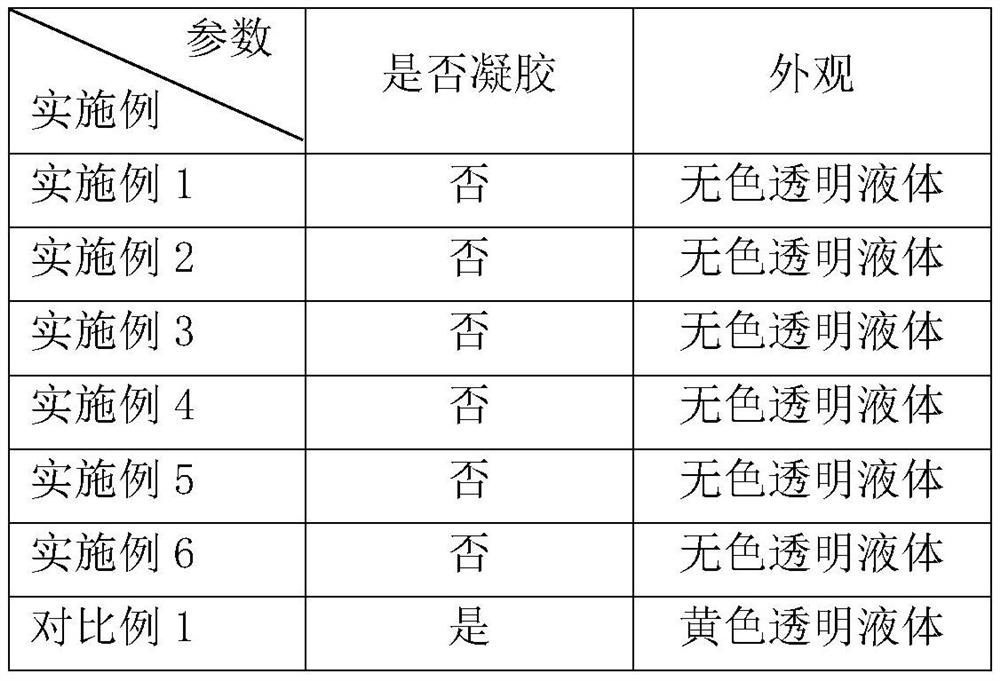

Examples

preparation example Construction

[0029] In a specific embodiment, the present invention provides a method for preparing a secondary aminosilane coupling agent, comprising the steps of:

[0030] Carrying out the Michael addition reaction of the pretreated allyl-terminated polyether and the terminal primary aminosilane coupling agent under a nitrogen atmosphere to obtain the secondary aminosilane coupling agent;

[0031] The allyl-terminated polyether is monofunctional and has a number average molecular weight of 300-3000;

[0032] The pretreatment method of the allyl polyether is: add 0.05-5% antioxidant to the allyl polyether, react at 60-100°C for 0.5-3h under the protection of nitrogen, and then -0.085--0.095 MPa pressure, vacuum dehydration at 90-120°C for 0.5-2h, then cool down to 40-60°C;

[0033] The terminal primary aminosilane coupling agent is γ-aminopropyltrimethoxysilane, γ-aminopropyltriethoxysilane, γ-aminopropylmethyldimethoxysilane, γ-aminopropyl One or two mixtures of methyldiethoxysilane; ...

Embodiment 1

[0043] In a four-necked flask equipped with a stirrer, a constant pressure dropping funnel, and an air duct, 100 parts of pretreated allyl-terminated polyether (S1010, Shanghai Dongda Chemical Co., Ltd.) with a number average molecular weight of 1000 were added successively, Introduce nitrogen and start stirring, drop γ-aminopropyltrimethoxysilane at 40°C, the molar ratio of terminal allyl polyether to γ-aminopropyltrimethoxysilane is 1:1, drop within 30 minutes After the addition is completed, the temperature is raised to 60° C. and reacted for 10 hours to obtain the secondary aminosilane coupling agent.

Embodiment 2

[0045] In a four-necked flask equipped with a stirrer, a constant pressure dropping funnel, and an air duct, 100 parts of pretreated allyl-terminated polyether (S1010, Shanghai Dongda Chemical Co., Ltd.) with a number average molecular weight of 1000 were added successively, Infuse nitrogen and start stirring, drop γ-aminopropyltriethoxysilane at 40°C, the molar ratio of terminal allyl polyether to γ-aminopropyltriethoxysilane is 1:1, 30 minutes After the internal dropwise addition was completed, the temperature was raised to 90° C. and reacted for 4 hours to obtain the secondary aminosilane coupling agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com