Microwave synthesis method of supported molecular sieve membrane

A microwave synthesis, supported technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, membranes, etc., can solve problems such as poor product performance stability, and achieve the advantages of prolonging aging time, reducing energy consumption and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] As a preferred embodiment, the present invention provides a synthetic method that is specifically applicable to supported type A molecular sieve membranes, the method comprising the following steps:

[0018] ① Use deionized water as a solvent to prepare a synthetic solution, which contains 2 to 5 mol / L Na in terms of molar concentration a O, 0.04~0.06mol / LAL 2 o 3 , and 0.2~0.6mol / L SiO 2 .

[0019] ②Aging: Put the tubular support made of alumina and the synthesis solution in the reaction kettle, and put it in the microwave oven for synthesis, and let it stand at 30-45°C for 16-20 hours to fully age;

[0020] ③Heating up: Use a microwave oven to supply energy, and slowly heat up to the synthesis temperature in 3 to 6 minutes;

[0021] ④Synthesis: Use a microwave oven to supply energy, and synthesize at 80-120°C for 7-9 minutes;

[0022] ⑤ washing and drying;

[0023] ⑥Repeat the above operations ①~⑤, 2~3 times.

Embodiment 1

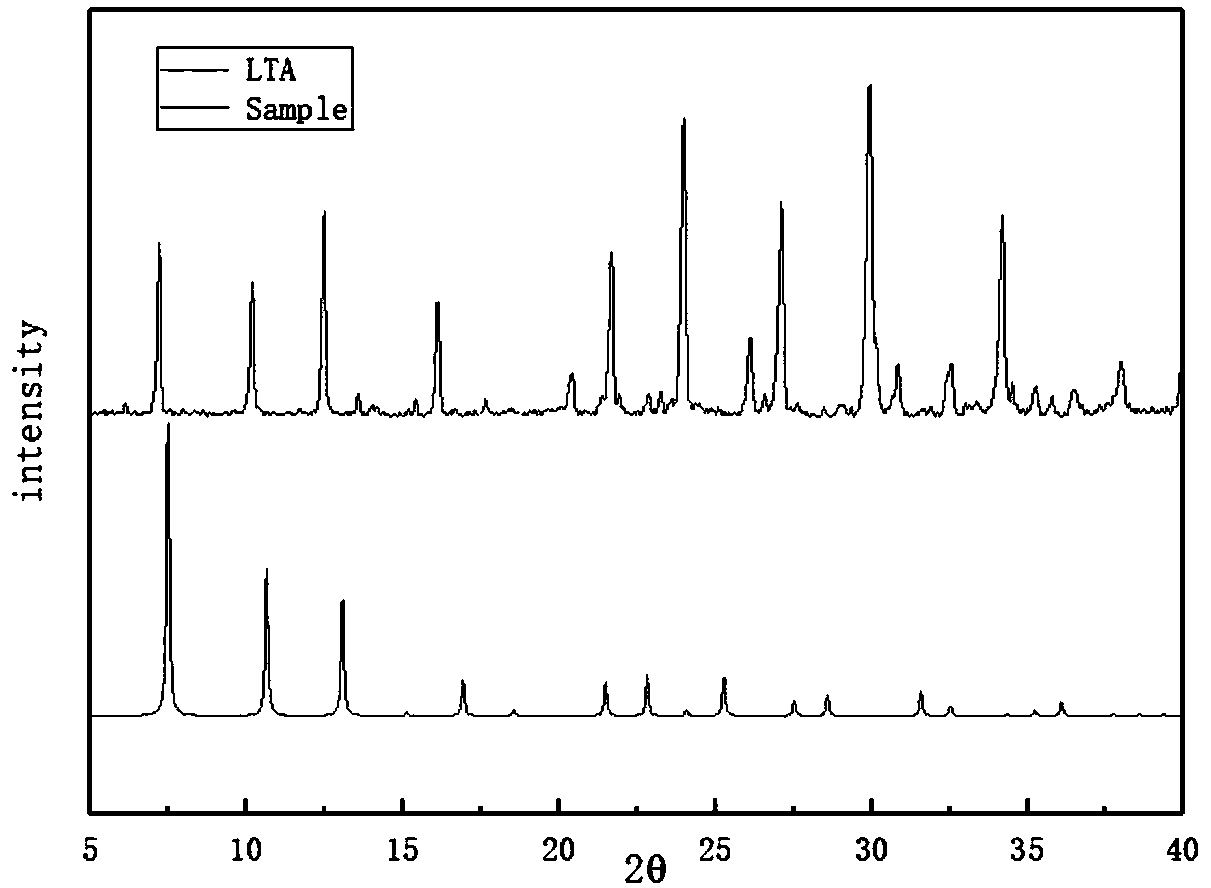

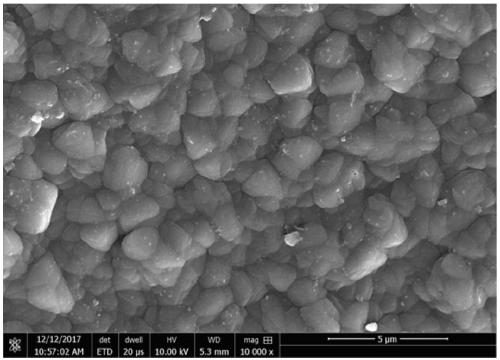

[0037] The preparation of LTA type molecular sieve membrane product I comprises the following steps

[0038](1) Prepare synthetic liquid I according to the following method;

[0039] Prepare Solution A 1 : Dissolve 15.0 grams of NaOH in 100 ml of deionized water, then add 0.54 grams of metal aluminum foil, and dissolve to obtain solution A 1 ;

[0040] Solution B 1 : Dissolve 25.0 grams of NaOH in 75ml of deionized water, then add 10ml of silica sol (which contains SiO 2 The mass percentage composition is 30%), dissolves and obtains solution B 1 ;

[0041] Solution A 1 and solution B 1 Mix well to obtain a uniform and clear synthetic solution I. In the resulting synthetic liquid I, the contained substances are converted into 50Na according to the molar ratio 2 O: Al 2 o 3 :5SiO2 2 :1010H 2 O. The corresponding converted molar concentrations are: Na 2 O, 2.64mol / L; Al 2 o 3 , 0.053mol / L; SiO 2 , 0.263mol / L.

Embodiment 2

[0049] Preparation of LTA-type molecular sieve membrane product II

[0050] (1) Prepare Synthetic Solution II as follows:

[0051] Prepare solution A 2 : Dissolve 429 grams of NaOH in 2000ml deionized water, then add 42.3 grams of sodium metaaluminate, and dissolve to obtain solution A 2 ;

[0052] Prepare Solution B 2 : Dissolve 429 grams of NaOH in 2000ml deionized water, then add 343 grams of sodium silicate nonahydrate, dissolve to obtain solution B 2 ;

[0053] Solution A 2 and solution B 2 Mix well to get uniform and clear Synthetic Liquid II. In the obtained synthetic solution II, the contained substances are converted according to the molar ratio: 51Na 2 O: Al 2 o 3 :5SiO2 2 :1030H 2 O. The corresponding molar concentration is: Na 2 O, 2.64mol / L; Al 2 o 3 , 0.053mol / L; SiO 2 , 0.263mol / L.

[0054] (2) A tubular porous alumina ceramic support body with a length of 1030mm and a diameter of 1.2cm is fixed with a bracket, placed vertically in a polytetraf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com