A kind of high-strength ceramic fiber thermal insulation material and preparation method thereof

A technology of ceramic fiber and heat insulating material, applied in the field of high-strength ceramic fiber heat insulating material and its preparation, can solve the problems of increasing the weight of the fiber heat insulating material, poor mechanical properties of the heat insulating material, affecting the heat insulating effect of the material, etc. The effect of high strength, short reaction time and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a high-strength ceramic fiber thermal insulation material, comprising the following steps:

[0025] 1) Weigh the ceramic fiber material, place it in the acetate solution (15% to 30% by weight) of the corresponding metal of the ceramic fiber material, and mix evenly. 25-65%; the ceramic fiber material is alumina fiber, zirconia fiber, aluminum silicate fiber or mullite fiber; the acetate solution is aluminum acetate solution or zirconium acetate solution, which is based on the selected ceramic The fiber material is selected to ensure the purity of the ceramic fiber material after processing.

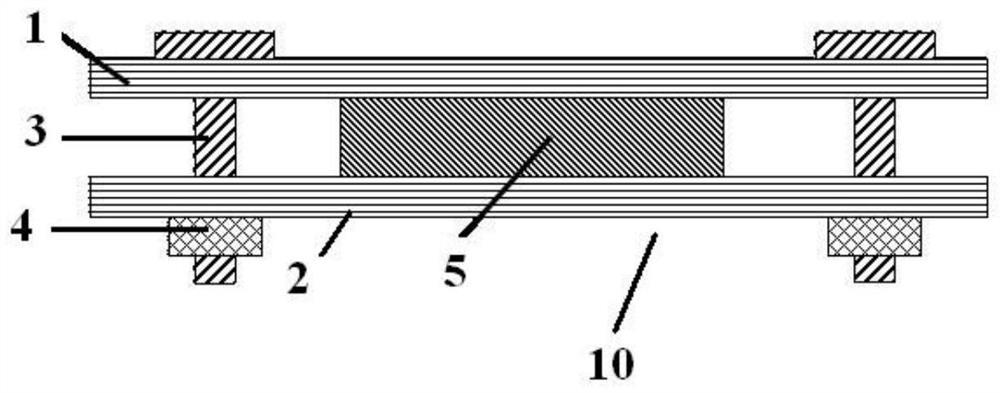

[0026] 2) the mixed slurry 5 that step 1) obtains is packed in the metal splint mold 10, as figure 1 As shown, the metal splint mold 10 includes a first metal panel 1 and a second metal panel 2 arranged in parallel, and the first metal panel 1 and the second metal panel 2 are connected by a plurality of bolts 3 and nuts 4 that cooperat...

Embodiment 1

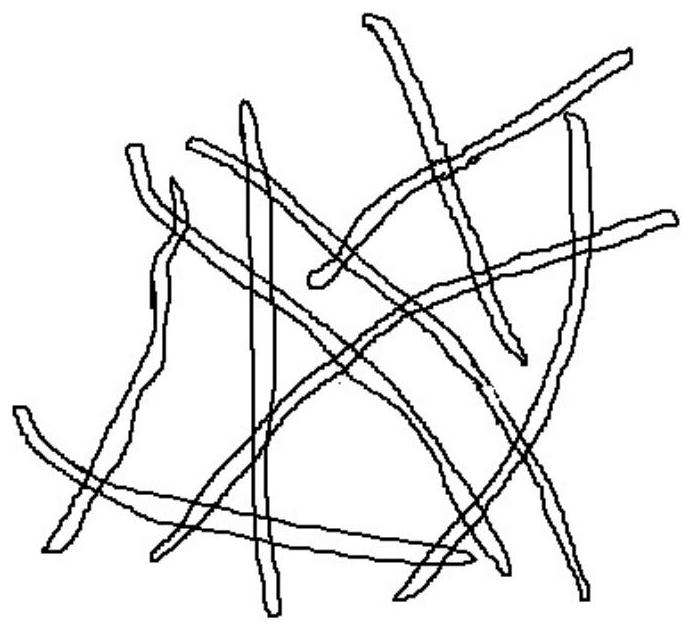

[0029] Take the alumina ceramic fiber material, put it into the aluminum acetate solution with a concentration of 15wt%, the amount of the aluminum acetate solution is 25% of the alumina fiber material, mix the two evenly, and pour the prepared mixed slurry into the metal splint mold , the pressure applied on the metal splint mold is 3MPa, put the metal splint mold with the mixed slurry in the oven, the oven is slowly heated to 150°C, and after the sample is kept for 12 hours, the oven is closed and the temperature is naturally cooled to room temperature , take out the sample from the metal splint mold and place it in an oven, continue drying at 100°C for 12 hours, take it out, and cool it naturally again to obtain a high-strength alumina ceramic fiber material. figure 2 It is a schematic diagram of the structure of the original alumina ceramic fiber material in this embodiment. The original alumina ceramic fiber material is simply intertwined at the fiber overlapping point, ...

Embodiment 2

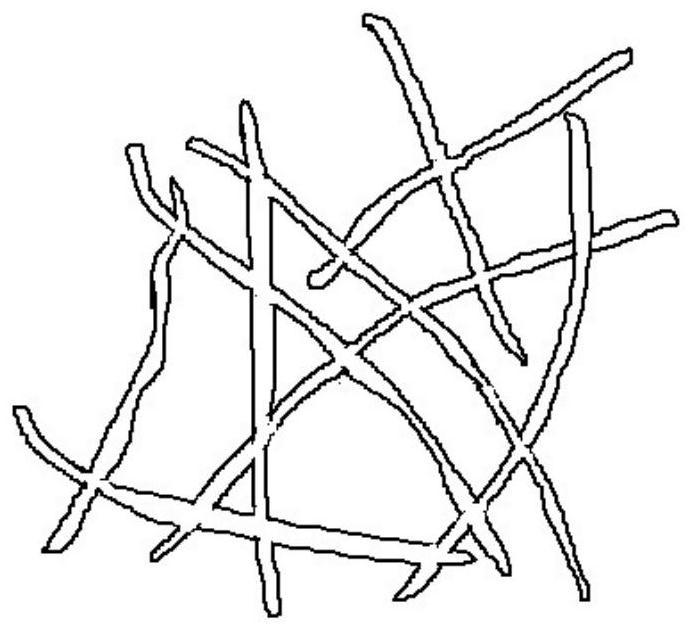

[0031] Take the zirconia ceramic fiber material, put it into the zirconium acetate solution with a concentration of 20wt%, the amount of the zirconium acetate solution is 35% of the zirconia fiber material, mix the two evenly, pour the prepared mixed slurry into the metal splint mold , the pressure applied on the metal splint mold is 5MPa, put the metal splint mold with the mixed slurry in the oven, and the oven is slowly heated to 220°C, and after the sample is kept warm and pressured for 8 hours, the oven is closed and the temperature is naturally cooled to room temperature , Take out the sample in the metal splint mold and put it in an oven, continue drying at 120°C for 12 hours, take it out, and cool it naturally again to obtain a high-strength zirconia ceramic fiber material. figure 2 and image 3 It is a schematic structural diagram of the original zirconia ceramic fiber material and the treated zirconia ceramic fiber material in this embodiment, and the effect after fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com