Method for enhanced phosphorus removal of membrane bioreactor

A technology of membrane bioreactor and chemical phosphorus removal, which is applied in the direction of chemical instruments and methods, biological treatment devices, biological water/sewage treatment, etc., and can solve the problems of unsatisfactory phosphorus removal effect, decreased membrane flux, and chemical sludge membrane hazards To achieve the effect of reducing phosphorus removal effect and the adverse effects of membrane flux and membrane service life, improving efficiency and effect, and ensuring phosphorus removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

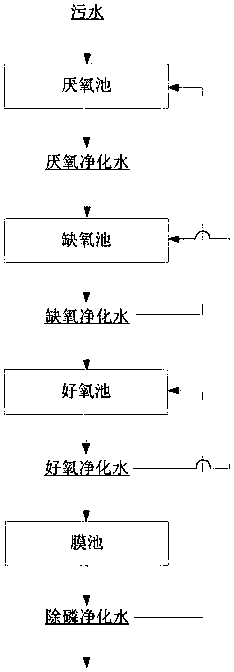

Method used

Image

Examples

Embodiment 1

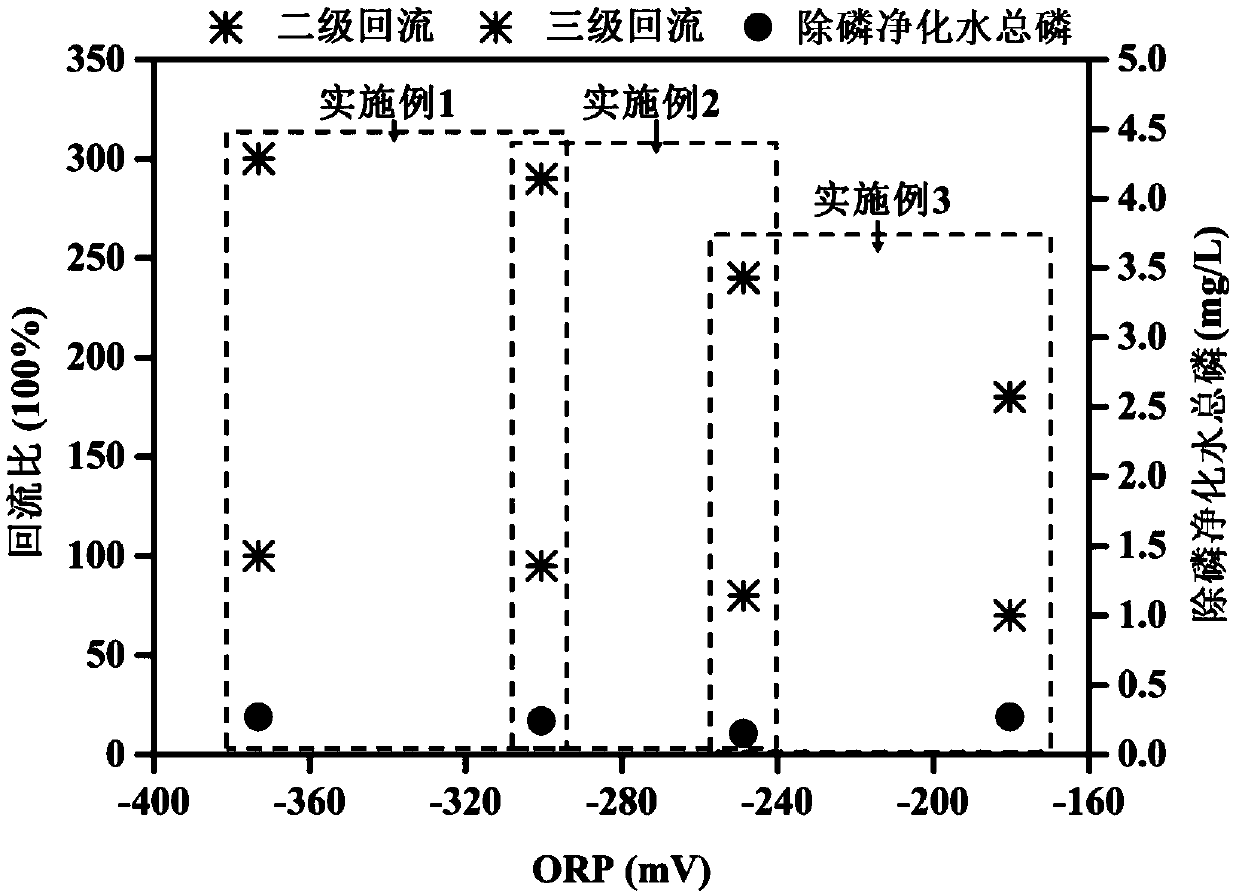

[0052] The COD value of sewage influent decreased from 216mg / L to 165mg / L within two weeks, and the ORP value in the anaerobic pool in the biochemical area increased from -373.21mV to -300.56mV due to the large fluctuation of influent pollutant load. like figure 2 As shown, only by adjusting the secondary reflux ratio from 300% to 290%, and the tertiary reflux ratio from 100% to 95%, the phosphorus removal efficiency reaches 92.13%, and the total phosphorus concentration of phosphorus removal purified water is 0.24mg / L, reaching the effluent discharge standard.

Embodiment 2

[0054] Further monitoring on the basis of Example 1 showed that the ORP value of the anaerobic pool in the biochemical zone increased from -300.56mV to -248.68mV within one month due to the large fluctuation of pollutant load in the sewage inflow. like figure 2 As shown, only by adjusting the secondary reflux ratio from 290% to 240%, and the tertiary reflux ratio from 95% to 80%, the phosphorus removal efficiency reaches 92.57%, and the total phosphorus concentration of phosphorus removal purified water is 0.15mg / L, reaching the effluent discharge standard.

Embodiment 3

[0056] On the basis of Example 2, further monitoring showed that the ORP value of the anaerobic pool in the biochemical zone increased from -248.68mV to -180.34mV within one month due to the large fluctuation of pollutant load in the sewage inflow. like figure 2 As shown, the secondary reflux ratio is reduced from 240% to 180%, and the tertiary reflux ratio is reduced from 80% to 70% only by adjustment. The phosphorus removal efficiency reaches 84.02%, and the total phosphorus concentration of the phosphorus removal purified water is 0.27mg / L, reaching the effluent discharge standard.

[0057] Conclusion: As can be seen from Examples 1-3, by reducing the secondary reflux ratio and the tertiary reflux ratio, the amount of dissolved oxygen in the aerobic tank refluxed to the anoxic tank and the anaerobic tank is reduced, and the anaerobic tank is ensured. Oxygen environment and good anaerobic phosphorus release efficiency not only effectively improve the efficiency of phosphor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com