1-methylcyclopropylene sustained release adhesive and preparation and applications thereof

A technology of methylcyclopropene and slow-release glue, applied in the application, protecting fruits/vegetables, food ingredients, etc. with a protective layer, can solve the problem of reducing the use efficiency of 1-methylcyclopropene, increasing the workload and cost, Complex preparation process and other problems, to achieve the effect of green and non-toxic raw materials, labor saving, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

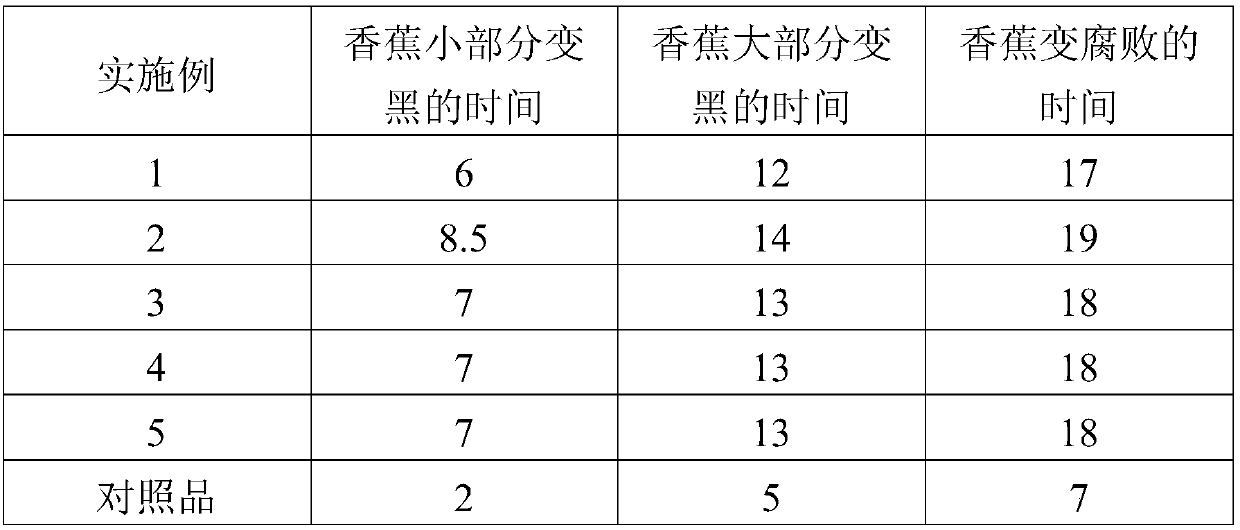

Examples

Embodiment 1

[0035] This embodiment provides a 1-methylcyclopropene slow-release adhesive and a preparation method thereof.

[0036] (1) dissolving gelatin in 100ml deionized water to obtain a gelatin solution with a mass fraction of 3wt.%, cooling in an ice bath, controlling the temperature of the solution to be 1 to 4°C, adding 1-methylcyclocycline equivalent to 20% by weight of gelatin Propylene was stirred at 800rpm for 0.5h to form a homogeneous suspension, ground, stood still for 6h, filtered with suction to obtain a precipitate, washed with water to obtain 1-methylcyclopropene clathrate, and stored at 4°C for later use.

[0037] (2) Dissolve 6g sodium carboxymethylcellulose, 5g chitosan quaternary ammonium salt and 12g starch in 65ml deionized water, add 1-methylcyclopropene clathrate and 7g propylene glycol prepared by 5g step (1) successively , stirred at 1000rpm for 1.5h to obtain a uniform viscous jelly, which is the 1-methylcyclopropene slow-release adhesive, and stored at 4°C....

Embodiment 2

[0039] This embodiment provides a 1-methylcyclopropene slow-release adhesive and a preparation method thereof.

[0040] (1) Dissolve β-cyclodextrin in 100ml of deionized water to obtain a β-cyclodextrin solution with a mass fraction of 8wt.%, cool in an ice bath, control the temperature of the solution at 1-4°C, and add the equivalent of β-cyclodextrin 1-methylcyclopropene with 30% weight of cyclodextrin, stirred at 800rpm for 0.5h to form a uniform suspension, ground, stood still for 12h, filtered with suction to obtain precipitate, washed with water to obtain 1-methylcyclopropene clathrate were stored at 4°C for later use.

[0041] (2) 12g sodium carboxymethylcellulose, 10g chitosan quaternary ammonium salt and 12g carboxymethylcellulose are dissolved in 25ml deionized water, and 1-methylcyclopropene prepared by 15g step (1) is added successively for clathrate material and 14g of aloe vera juice, stirred at 1000rpm for 1.5h to obtain a uniform viscous jelly, which is the 1-...

Embodiment 3

[0043] This embodiment provides a 1-methylcyclopropene slow-release adhesive and a preparation method thereof.

[0044] (1) Dissolve polyacrylamide in 100ml deionized water to obtain a polyacrylamide solution with a mass fraction of 5wt.%, cool in an ice bath, control the temperature of the solution at 1-4°C, and add 25% polyacrylamide equivalent to the weight of polyacrylamide 1-methylcyclopropene, stirred at 800rpm for 0.5h to form a uniform suspension, ground, stood still for 9h, filtered with suction to obtain a precipitate, washed with water to obtain 1-methylcyclopropene clathrate, at 4°C Save for later.

[0045] (2) Dissolve 9g sodium carboxymethylcellulose, 7.5g chitosan quaternary ammonium salt, 8g rosin and 10g peach gum in 45ml deionized water, and add 10g of 1-methylcyclopropene package prepared in step (1) successively Compound and 10.5g glycerol, stirred at 1000rpm for 1.5h to obtain a uniform viscous jelly, which is the 1-methylcyclopropene slow-release adhesiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com