Cotton moulding topping-free agent and preparation method thereof

A technology of topping agent and cotton, applied in botanical equipment and methods, biocides, animal repellents, etc., can solve the problems of cotton fiber quality and yield threats, low peach setting rate, stimulation of normal functions, etc. The effect of improving the degree of mechanization, improving output and fiber quality, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

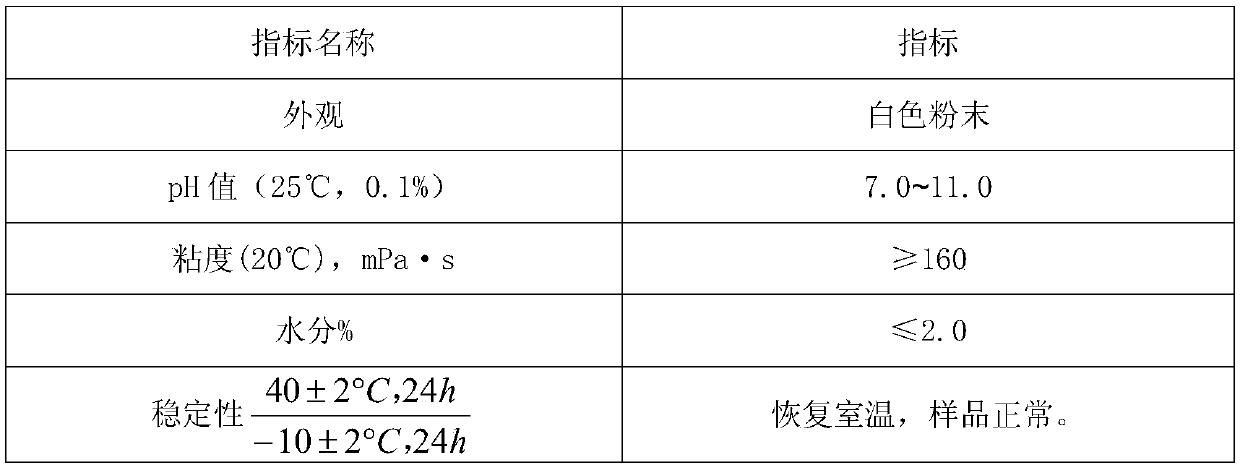

[0037] A kind of cotton molding free topping agent of the present invention and preparation method thereof are as follows:

[0038] (1) Take 430 grams of cool and dry cottonseed and crush it into 800-mesh fine powder, and then 500 grams of fresh and cool and dry

[0039] gram of cotton leaf is crushed into 1000 mesh fine powder, then mixed and stirred evenly to make A preparation;

[0040] (2) Add 5580 grams of warm water at 30-36 degrees to the preparation of item A, soak for 1.5 hours, stir well to make it

[0041] Suspend, 200 grams of material A crystallize out of the suspension, filter, then store in the dark at room temperature, repeat steps (1) and (2) until 930 grams of material A are stored;

[0042] (3) 930 grams of material A and 70 grams of gossypol formic acid are mixed to form 1000 grams of wettable powder.

[0043] The empty container can be placed inside for 30 hours, and then the finished product can be packaged.

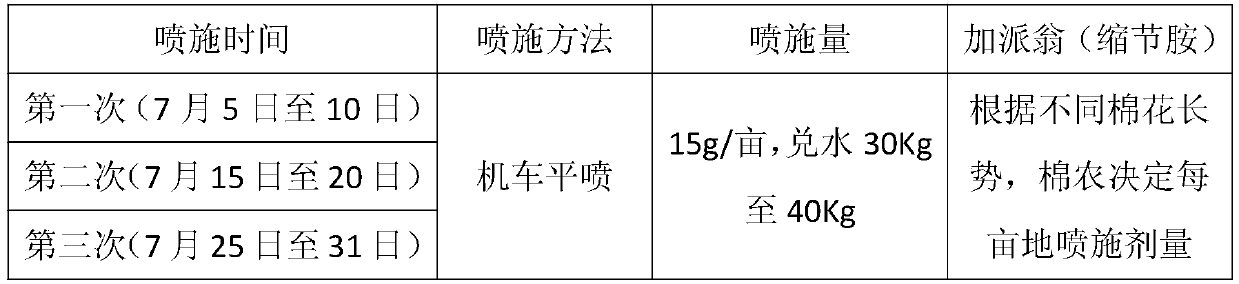

[0044] Instructions;

[0045] Configurati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com