Flexible self-supporting lithium ion battery negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as reduced battery life, reduced negative electrode conductivity, and increased internal resistance of batteries, so as to increase load capacity and improve Stability, the effect of reducing the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the lithium ion battery negative electrode material of the present embodiment comprises the following steps:

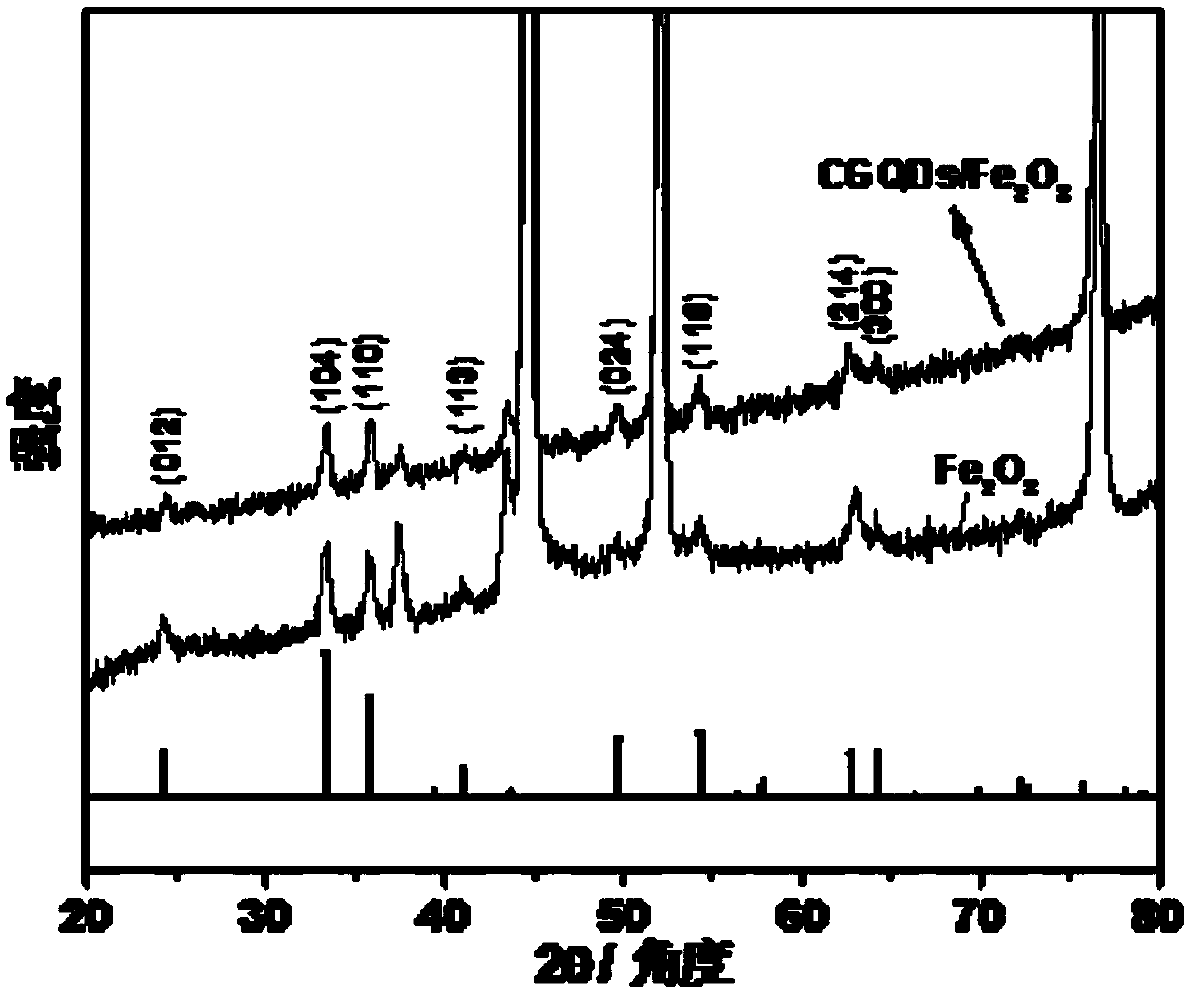

[0036] Step 1, 0.7g FeCl 3 ·6H 2 O and 0.45g (NH 4 ) 2 C 2 o 4 ·H 2 O was fully dissolved in 50mL by DMF and H 2 The iron precursor solution is obtained in the solution mixed with O, and the iron precursor solution is used as the electrolyte, the nickel foam is used as the working electrode, and the platinum sheet is used as the counter electrode at a current density of 7.8mA / cm 2 Under the conditions of constant current electrodeposition for 30min, the nickel foam after constant current electrodeposition was dried and placed in a tube furnace, and was calcined at 5°C / min to 500°C for 2h under the condition of air atmosphere to obtain Fe 2 o 3 Self-supporting substrate; DMF and H in the mixed solution 2 The volume ratio of O is 2:1;

[0037] Step 2: Add 100 mg of Taixi anthracite coal powder with a particle size of no more t...

Embodiment 2

[0044] The preparation method of the lithium ion battery negative electrode material of the present embodiment comprises the following steps:

[0045] Step 1, 0.7g FeCl 3 ·6H 2 O and 0.45g (NH 4 ) 2 C 2 o 4 ·H 2 O was fully dissolved in 50mL by DMF and H 2 The iron precursor solution is obtained in the solution mixed with O, and the iron precursor solution is used as the electrolyte, the nickel foam is used as the working electrode, and the platinum sheet is used as the counter electrode at a current density of 7.8mA / cm 2 Under the conditions of constant current electrodeposition for 30min, the nickel foam after constant current electrodeposition was dried and placed in a tube furnace, and was calcined at 5°C / min to 450°C for 2h under the condition of air atmosphere to obtain Fe 2 o 3 Self-supporting substrate; DMF and H in the mixed solution 2 The volume ratio of O is 1:1;

[0046] Step 2: Add 100mg of Taixi anthracite coal powder into a round bottom flask containi...

Embodiment 3

[0049] The preparation method of the lithium ion battery negative electrode material of the present embodiment comprises the following steps:

[0050] Step 1, 0.6g FeCl 3 ·6H 2 O and 0.45g (NH 4 ) 2 C 2 o 4 ·H 2 O was fully dissolved in 50mL by DMF and H 2 The iron precursor solution is obtained in the solution mixed with O, and the iron precursor solution is used as the electrolyte, the nickel foam is used as the working electrode, and the platinum sheet is used as the counter electrode at a current density of 9.1mA / cm 2 Under the conditions of constant current electrodeposition for 20min, the nickel foam after constant current electrodeposition was dried and placed in a tube furnace, and it was calcined at 3°C / min to 450°C for 2h under the condition of air atmosphere to obtain Fe 2 o 3 Self-supporting substrate; DMF and H in the mixed solution 2 The volume ratio of O is 3:1;

[0051] Step 2: Add 50mg of Taixi anthracite coal powder into a round-bottomed flask cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com