Surface manufacturing process of pulp molded product

A technology of surface processing and pulp molding, which is applied in the direction of textiles and papermaking, printing, printing machines, etc., can solve the problems of paper-plastic objects offset, affect the quality of ink printing, and large economic losses, and achieve sufficient drying and screen printing dots Clear, Penetrating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

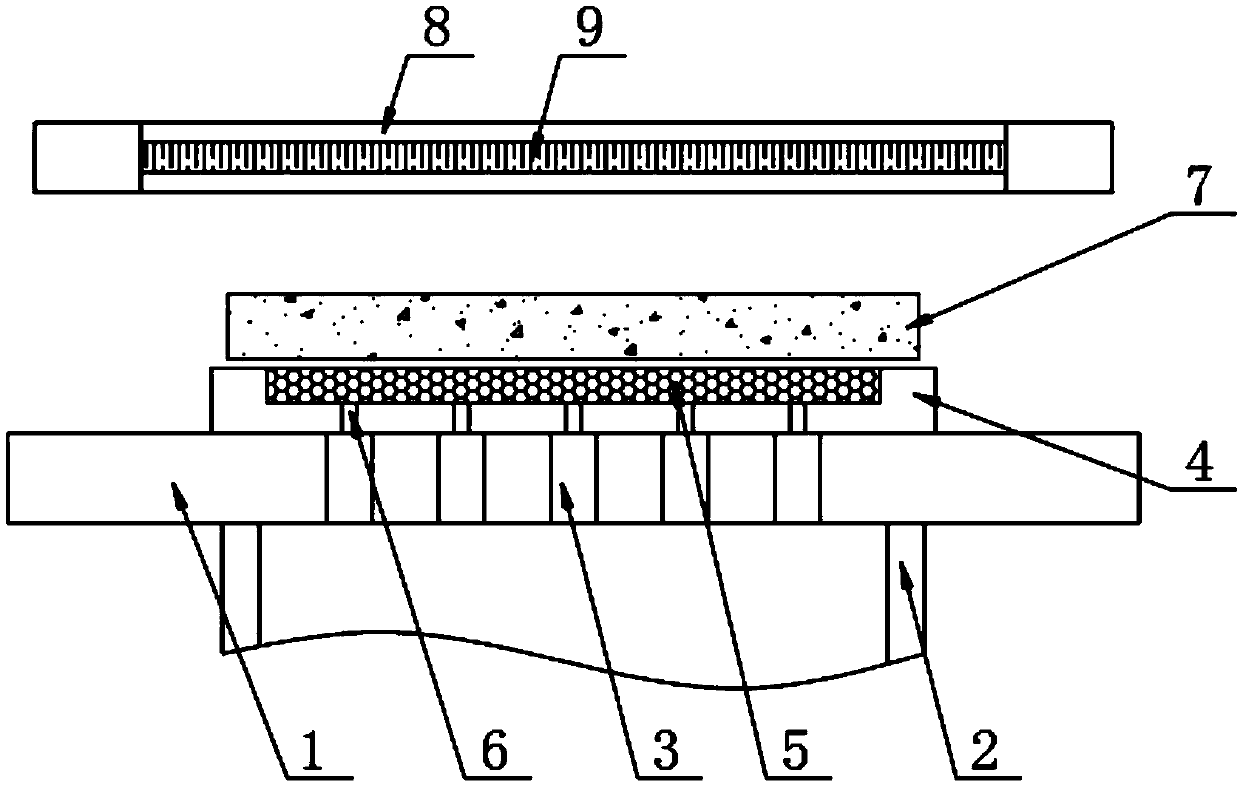

[0023] The present invention provides such figure 1 The surface processing device for pulp molded products includes a table top 1, the bottom of the table top 1 is provided with a connecting pipe 2, the surface of the table top 1 is provided with a first through hole 3, and the top surface of the table top 1 is provided with a place plate 4, the surface of the placing plate 4 is provided with a screen 5, the bottom of the screen 5 is provided with a second through hole 6, the top of the placing plate 4 is provided with a paper plastic 7, and the top of the paper plastic 7 is provided with a net Frame 8, the inner side of the screen frame 8 is provided with a silk screen 9, the screen frame 8 is set correspondingly to the paper plastic 7 through the silk screen 9, the paper plastic 7 is correspondingly set to the screen 5, and the screen 5 is connected to the first The two through holes 6 are connected.

[0024] The effect of the technical solution of this embodiment is: the s...

Embodiment 2

[0026] A surface processing technology for pulp molded products, comprising the following steps:

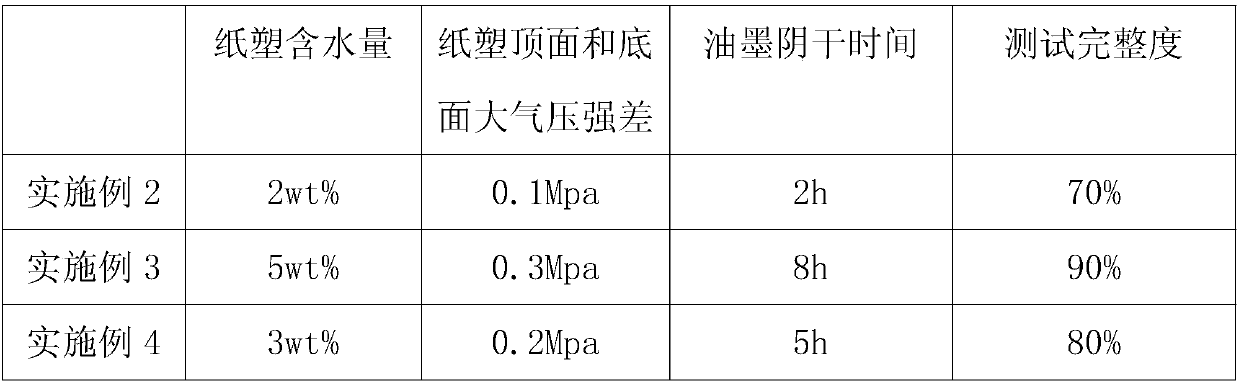

[0027] Step 1, mold selection: select the semi-finished paper plastic 7 with good surface forming effect, no damage and strong integrity, and after the molded and finalized paper plastic 7 is finally manufactured, the water content on the surface of the paper plastic 7 is 2 wt%.

[0028] Step 2, placing objects: place the semi-finished paper plastic 7 produced by molding on the screen 5 on the top surface of the placement plate 4 for positioning, manually adjust the limit of the screen frame 8 to the surface of the paper plastic 7, and perform the limit and adjustment The screen printing screen 9 position, the printing position is aligned with the area to be printed on the surface of the paper plastic 7, and the force of the scraper is manually operated to adjust the ink force and the thickness of the ink layer. The screen printing screen 9 is in parallel contact with the top surf...

Embodiment 3

[0033] A surface processing technology for pulp molded products, comprising the following steps:

[0034] Step 1, mold selection: select a semi-finished paper plastic 7 with good surface forming effect, no damage and strong integrity, and after the molded paper plastic 7 is finally manufactured, the water content on the surface of the paper plastic 7 is 5 wt%.

[0035] Step 2, placing objects: place the semi-finished paper plastic 7 produced by molding on the screen 5 on the top surface of the placement plate 4 for positioning, manually adjust the limit of the screen frame 8 to the surface of the paper plastic 7, and perform the limit and adjustment The screen printing screen 9 position, the printing position is aligned with the area to be printed on the surface of the paper plastic 7, and the force of the scraper is manually operated to adjust the ink force and the thickness of the ink layer. The screen printing screen 9 is in parallel contact with the top surface of the paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com