Cooling system for power supply tank electrolyte prepared from molten anode aluminum foil of aluminum electrolytic capacitors and working method thereof

A technology of aluminum electrolytic capacitors and anode aluminum foil, which is applied in the direction of anodic oxidation, electrolytic process, electrolytic components, etc., can solve the problems of large occupied area of equipment, large operation noise pollution, high energy consumption of equipment, etc., to solve high energy consumption and High noise pollution, the effect of improving the secondary utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

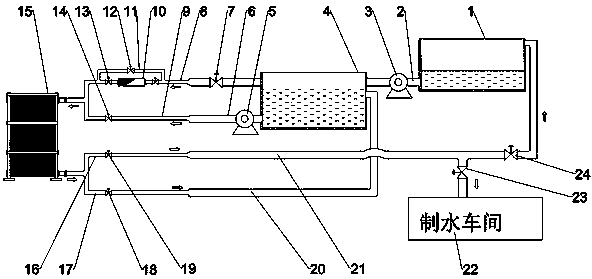

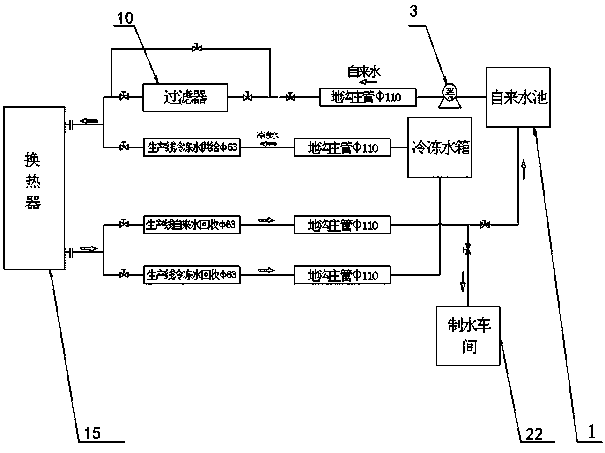

[0024] A cooling system for the electrolytic solution of a power supply tank formed by the anode aluminum foil of an aluminum electrolytic capacitor, comprising a tap water pool 1, a frozen water tank 4, and a heat exchanger 15; the bottom outlet of the tap water pool 1 is connected with a tap water outlet main pipe 2, and the tap water outlet The main pipe 2 is provided with a tap water pump 3 and a pneumatic valve I7. The tap water outlet pipe 2 is connected to the tap water supply pipe 8, and the tap water supply pipe 8 is connected to the inlet of the heat exchanger 15; The water outlet main pipe 6, the chilled water outlet main pipe 6 is provided with a chilled water pump 5, the chilled water outlet main pipe 6 is connected to one end of the chilled water supply pipe 9, and the other end of the chilled water supply pipe 9 is connected to the inlet of the heat exchanger 15 connected; said heat exchanger 15 bottom outlet is connected with tap water recovery pipe 16, and said...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com