Production process for hot-rolled acid-free acid pickling low-carbon steel plate

A low-carbon steel plate and production process technology, applied in the field of steel plate production technology, can solve the problems of pollution discharge, incoordination, harsh production environment, etc., and achieve the effect of simplifying the production line, facilitating control, and shortening the process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

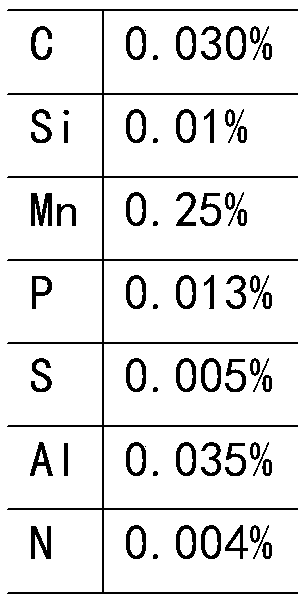

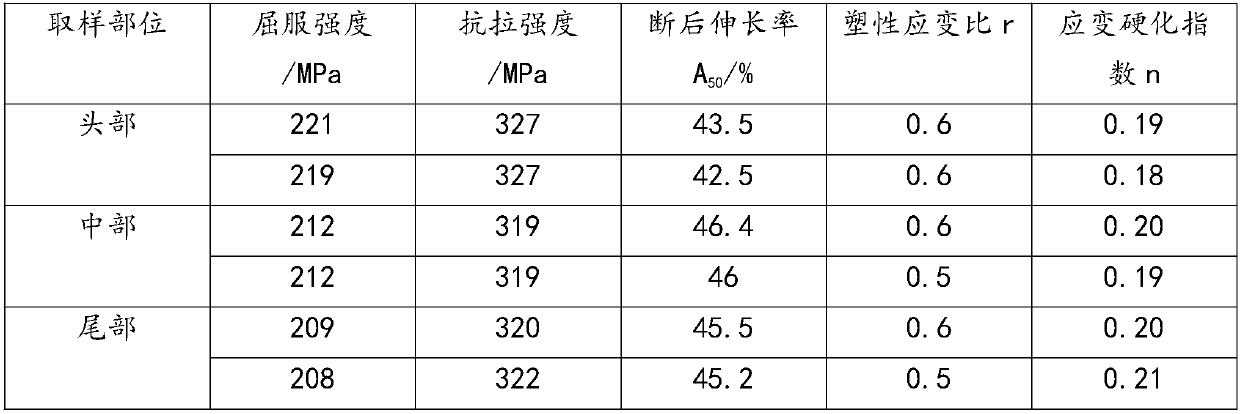

Embodiment 1

[0027] A production process of hot-rolled acid-free pickling low-carbon steel plate, including the production process of low-carbon steel plate and pickling process, specifically, the pickling process includes: decoiling the flattened steel plate, mechanical grinding pickling, mortar Pickling, crimping process.

[0028] The production process of the low-carbon steel plate includes molten iron pretreatment, converter smelting, out-of-furnace refining, slab continuous casting, walking heating furnace heating, rolling, laminar cooling water cooling, curling and leveling.

[0029] The mortar pickling includes the following steps: mixing water and gravel to form mortar, and projecting the mortar onto the surface of the low-carbon steel plate through a shot blaster, and the included angle between the projecting direction of the mortar and the low-carbon steel plate is 0-45°.

[0030] Preferably, the lateral width of the projection area of the mortar on the low carbon steel plate i...

Embodiment 2

[0054] A production process of hot-rolled acid-free pickling low-carbon steel plate, including the production process and pickling process of low-carbon steel plate, specifically,

[0055] The production process of the low-carbon steel plate includes molten iron pretreatment, converter smelting, out-of-furnace refining, slab continuous casting, walking heating furnace heating, rolling, laminar cooling water cooling, curling and leveling.

[0056] The pickling process includes: uncoiling the flattened steel plate, mechanical grinding pickling, mortar pickling, and curling processes. The mortar pickling includes the following steps: mixing water and gravel to form mortar, and projecting the mortar onto the surface of the low-carbon steel plate through a shot blaster, and the included angle between the projecting direction of the mortar and the low-carbon steel plate is 20°.

[0057] The lateral width of the projection area of the mortar on the low carbon steel plate is greater...

Embodiment 3

[0073] A production process of hot-rolled acid-free pickling low-carbon steel plate, including the production process of low-carbon steel plate and pickling process, specifically, the pickling process includes: decoiling the flattened steel plate, mechanical grinding pickling, mortar Pickling, crimping process.

[0074] The production process of the low-carbon steel plate includes molten iron pretreatment, converter smelting, out-of-furnace refining, slab continuous casting, walking heating furnace heating, rolling, laminar cooling water cooling, curling and leveling.

[0075] The mortar pickling includes the following steps: mixing water and gravel to form mortar, and projecting the mortar onto the surface of the low-carbon steel plate through a shot blaster, and the included angle between the projecting direction of the mortar and the low-carbon steel plate is 45°.

[0076] The lateral width of the projection area of the mortar on the low carbon steel plate is greater than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com