Bainitic steel for frog core rail and manufacturing method thereof

A bainitic steel and frog technology is applied in the field of bainitic steel for frog core rail and its manufacturing, which can solve the problems of uneven structure, peeling off blocks, unstable performance, etc., and achieve stable structure and performance, Optimized composition, avoids the effect of uneven tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 A kind of bainitic steel for frog core rail and its preparation method

[0037] The chemical composition (wt%) of the bainite steel for the frog rail in this embodiment is: C 0.30, Mn 1.79, Si 1.61, Cr 0.98, Ni 0.36, Mo 0.41, Cu 0.01, Al 0.007, V 0.10 , Ti 0.005, and the rest are iron and unavoidable impurities.

[0038] The bainite steel for the frog core rail of this embodiment is prepared through the following steps:

[0039] ①Bloom continuous casting: according to the conventional process of rail bloom continuous casting, the raw materials are smelted in a converter-refining-vacuum treatment-bloom continuous casting to obtain a steel billet with a size of 380×280mm;

[0040] ②Rolling process: the heating rate of the billet is ≤120°C / h, heated to 1250°C, the starting rolling temperature is 1150°C, and the final rolling temperature is 850°C, and the billet obtained in step ① is rolled into a rectangular billet of 185×125mm;

[0041] ③Forging process: the ...

Embodiment 2

[0045] Example 2 A kind of bainitic steel for frog core rail and its preparation method

[0046] The chemical composition (wt%) of the bainite steel for the frog rail in this embodiment is: C 0.30, Mn 1.79, Si 1.61, Cr 0.98, Ni 0.36, Mo 0.41, Cu 0.01, Al 0.007, V 0.10 , Ti 0.005, and the rest are iron and unavoidable impurities.

[0047] The bainite steel for the frog core rail of this embodiment is prepared through the following steps:

[0048] ① Bloom continuous casting: according to the conventional process of rail bloom continuous casting, the raw materials are smelted in a converter-refining-vacuum treatment-bloom continuous casting to obtain a billet with a size of 380*280mm;

[0049] ②Rolling process: the heating rate of the billet is ≤120°C / h, heated to 1250°C, the starting rolling temperature is 1150°C, and the final rolling temperature is 850°C, and the billet obtained in step ① is rolled into a rectangular billet of 185×125mm;

[0050] ③Forging process: the heat...

Embodiment 3

[0054] Example 3 A kind of bainitic steel for frog core rail and its preparation method

[0055] The bainite steel for frog core rail in this embodiment has the following chemical composition (wt%): C 0.29, Mn 1.78, Si1.60, Cr: 0.98, Ni: 0.35, Mo: 0.41, Cu: 0.01, Al : 0.007, V: 0.10, Ti: 0.005, and the rest are iron elements and unavoidable impurities.

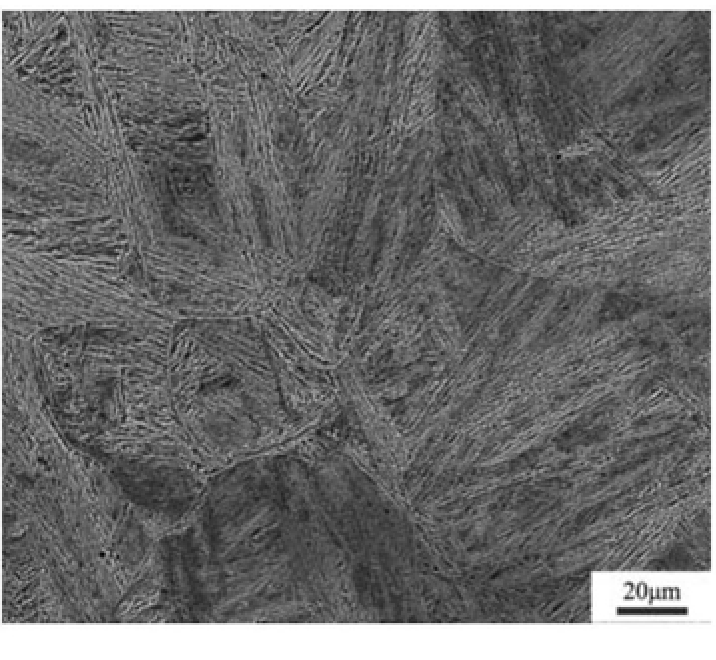

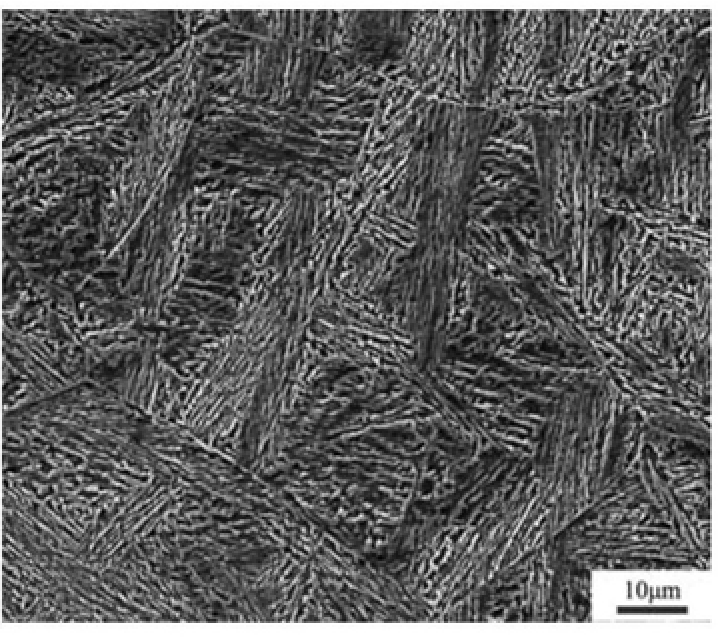

[0056] According to the same preparation method as Example 1, the bainite steel for frog rail of this embodiment was prepared. The mechanical properties of its service state are: R m =1353MPa, R p0.2 =1057Mpa, A=17%, Z=52%, A KU2 =85J, HRC=42.

[0057] The 500-fold and 1000-fold magnification microstructure images of the bainitic steel for frog core rails obtained in this example also show that the bainitic ferrite laths are evenly arranged (micrographs omitted).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com