Epoxy polyester orange-figure powder coating and preparation method thereof

A powder coating, epoxy polyester technology, applied in polyester coatings, epoxy resin coatings, coatings, etc., can solve the problems of inability to provide oil absorption, single, etc., to reduce the activation energy of cross-linking curing reaction, reduce drying The effect of baking temperature and increasing cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

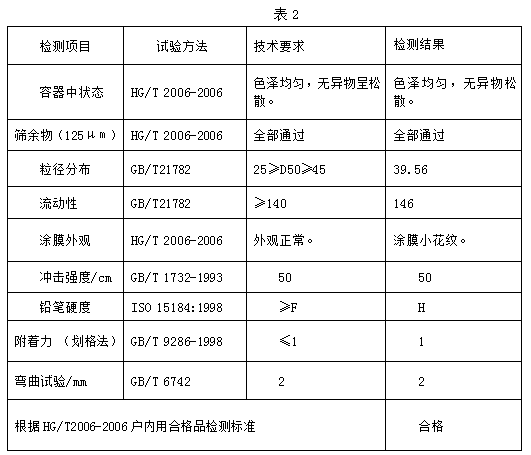

[0037] Example 1: Tianshui Great Wall Switch Co., Ltd. Light Gray Epoxy Polyester Orange Grain Powder Coating and Its Preparation

[0038] Prepare raw materials according to the following mass percentages: 20kg for epoxy resin E-12, 29kg for polyester resin 6041, 6kg for titanium dioxide R2196, 11kg for LB-160, 30kg for LG420, 1kg for 108-A booster, 1kg of 221 dry powder flow agent, 1kg of 701 wetting and dispersing agent, 0.5kg of benzoin, 0.1kg of A-601, 0.3kg of antioxidant 900 and 0.04kg of total pigment.

[0039] Preparation:

[0040] A. First turn on the power of the melting extruder, turn on the first zone and the second zone to heat up to 90°C in the first zone and 100°C in the second zone, and start the cooling cycle at the same time;

[0041] B. Accurately weigh the raw materials according to the above formula, pour them into a clean high-speed mixing and crushing tank with a rotation speed of 1000 rpm, and stir for three to five minutes;

[0042] C. The mixed raw ma...

Embodiment 2

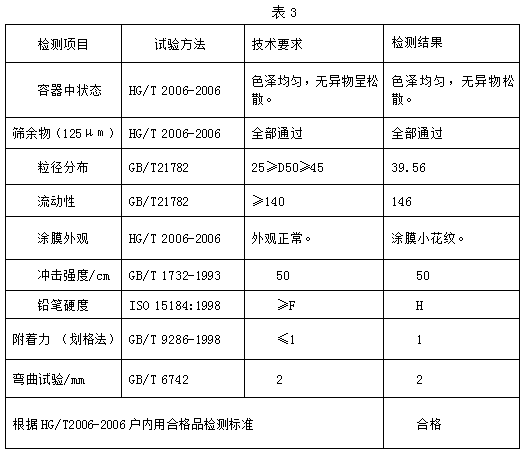

[0050] Example 2: Xinjiang Special Transformation Co., Ltd. European Gray Epoxy Polyester Orange Grain Powder Coating and Its Preparation

[0051] Prepare raw materials according to the following mass percentages: 22kg for epoxy resin E-12, 30kg for polyester resin 6041, 7kg for titanium dioxide R2196, 9kg for LB-160, 27kg for LG420, 1.2kg for 108-A booster , 1.2kg of 221 dry powder flow agent, 1.2kg of 701 wetting and dispersing agent, 0.8kg of benzoin, 0.2kg of A-601, 0.5kg of antioxidant 900 and 0.06kg of total pigment.

[0052] Preparation:

[0053] A. First turn on the power supply of the melting extruder, turn on the first zone and the second zone to heat up to the temperature of the first zone 100 ℃, the temperature of the second zone 110 ℃, and start the cooling cycle at the same time;

[0054] B. Accurately weigh the raw materials according to the above formula, pour them into a clean high-speed mixing and crushing tank with a rotation speed of 1500 rpm, and stir for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com