Self-luminous epoxy resin mortar paint and preparation method thereof

A light epoxy resin, epoxy resin technology, applied in epoxy resin coatings, luminescent coatings, coatings and other directions, can solve the problems of high performance requirements of the mixture, difficult to achieve the use effect, affecting the warning effect, etc. Anti-scratch performance, wide range of use, good warning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

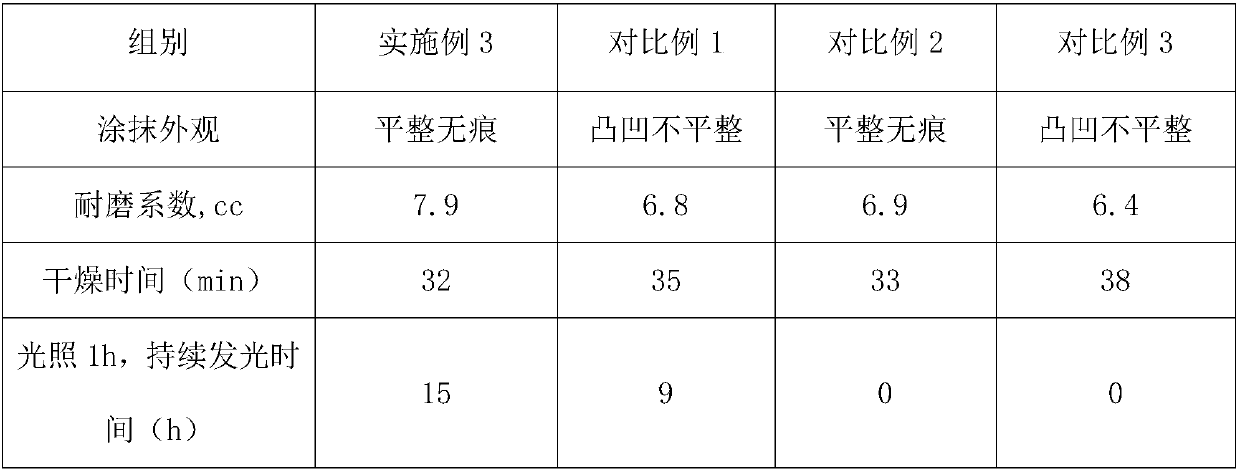

Examples

Embodiment 1

[0026] A self-luminous epoxy resin mortar paint, comprising the following raw materials in parts by weight: 40 parts of talcum powder, 100 parts of epoxy resin, 25 parts of polyurethane, 6 parts of absolute ethanol, 12 parts of mica powder, and 11 parts of luminous powder , 8 parts of dispersant, 7 parts of defoamer, 8 parts of accelerator, and 5 parts of coupling agent.

[0027] Further, the dispersant is a xylene solution of methyl silicone oil, and the mass concentration of methyl silicone oil is 3%.

[0028] Further, the defoamer is emulsified silicone oil.

[0029] Further, the accelerator is an organic urea accelerator.

[0030] Further, the coupling agent is a silane coupling agent, and the silane coupling agent is vinyltrimethoxysilane.

[0031] Based on the preparation method of the self-luminous epoxy resin mortar paint, the steps are as follows:

[0032] 1) Prepare mixed powder:

[0033] a. Preparation of luminous powder: Take luminous powder and add it to absol...

Embodiment 2

[0041] A self-luminous epoxy resin mortar paint, comprising the following raw materials in parts by weight: 55 parts of talcum powder, 120 parts of epoxy resin, 41 parts of polyurethane, 13 parts of absolute ethanol, 27 parts of mica powder, and 25 parts of luminous powder , 17 parts of dispersant, 15 parts of defoamer, 16 parts of accelerator, and 19 parts of coupling agent.

[0042] Further, the dispersant is a xylene solution of methyl silicone oil, and the mass concentration of methyl silicone oil is 3%.

[0043] Further, the defoamer is a polyether defoamer.

[0044] Further, the accelerator is an organic urea accelerator.

[0045] Further, the coupling agent is a silane coupling agent, and the silane coupling agent is vinyltriethoxysilane.

[0046] Based on the preparation method of the self-luminous epoxy resin mortar paint, the steps are as follows:

[0047] 1) Prepare mixed powder:

[0048] a. Preparation of luminous powder: Take luminous powder and add it to abso...

Embodiment 3

[0056] A self-luminous epoxy resin mortar paint, comprising the following raw materials in parts by weight: 48 parts of talcum powder, 110 parts of epoxy resin, 33 parts of polyurethane, 9 parts of absolute ethanol, 20 parts of mica powder, and 18 parts of luminous powder , 12 parts of dispersant, 11 parts of defoamer, 11 parts of accelerator, 11 parts of coupling agent.

[0057] Further, the dispersant is a xylene solution of methyl silicone oil, and the mass concentration of methyl silicone oil is 3%.

[0058] Further, the defoamer is emulsified silicone oil.

[0059] Further, the accelerator is an organic urea accelerator.

[0060] Further, the coupling agent is a silane coupling agent, and the silane coupling agent is vinyltrimethoxysilane.

[0061] Based on the preparation method of the self-luminous epoxy resin mortar paint, the steps are as follows:

[0062] 1) Prepare mixed powder:

[0063] a. Preparation of luminous powder: Take luminous powder and add it to absol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com