Method for preparing nicorandil tripolymer

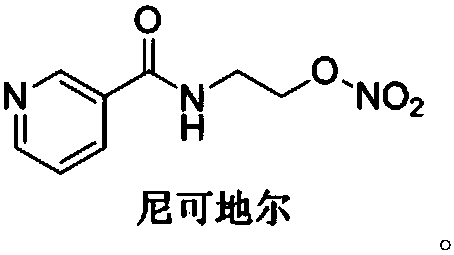

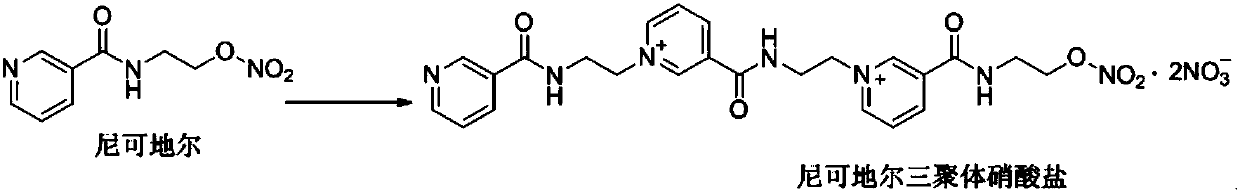

A nicorandil trimer, solid technology, which is applied in the field of preparation of nicorandil trimer, can solve the problem of low yield of nicorandil trimer, difficulty in obtaining, and limitation of nicorandil tripolymer. The research work of polymer impurities and other problems can achieve the effect of rapid acquisition, good purity and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Dissolve Nicorandil (1.0g) in DMA (2mL), stir in an oil bath at 100°C for 4.0h, slowly cool to room temperature, slowly add carbon tetrachloride dropwise, stir and crystallize, a large amount of solids precipitate, filter, The crude product was obtained by washing with tetrahydrofuran, and recrystallized from tetrahydrofuran to obtain 826.2 mg of nicorandil trimer nitrate as a white solid with a purity of 99.89%.

Embodiment 2

[0023] Dissolve Nicorandil (1.0g) in DMA (3mL), stir in an oil bath at 90°C for 5.0h, slowly cool to room temperature, slowly add chloroform dropwise, stir and crystallize, a large amount of solids precipitate out, filter and wash with acetonitrile to obtain The crude product was recrystallized from acetonitrile to obtain 837.4 mg of nicorandil trimer nitrate as a white solid with a purity of 99.91%.

Embodiment 3

[0025] Dissolve Nicorandil (1.0g) in DMF (3mL), stir in an oil bath at 80°C for 6.0h, slowly cool to room temperature, slowly add dichloromethane dropwise, stir and crystallize, a large amount of solid precipitates, filter, and The crude product was obtained by washing with nitrile, and recrystallized from propionitrile to obtain 855.9 mg of nicorandil trimer nitrate as a white solid with a purity of 99.93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com