Low SFD magnetic recording material and preparation method thereof

A magnetic recording and oxide technology, applied in the field of magnetic information materials, can solve problems such as restricting applications, and achieve the effects of ensuring magnetic properties, refining particle size, and changing magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

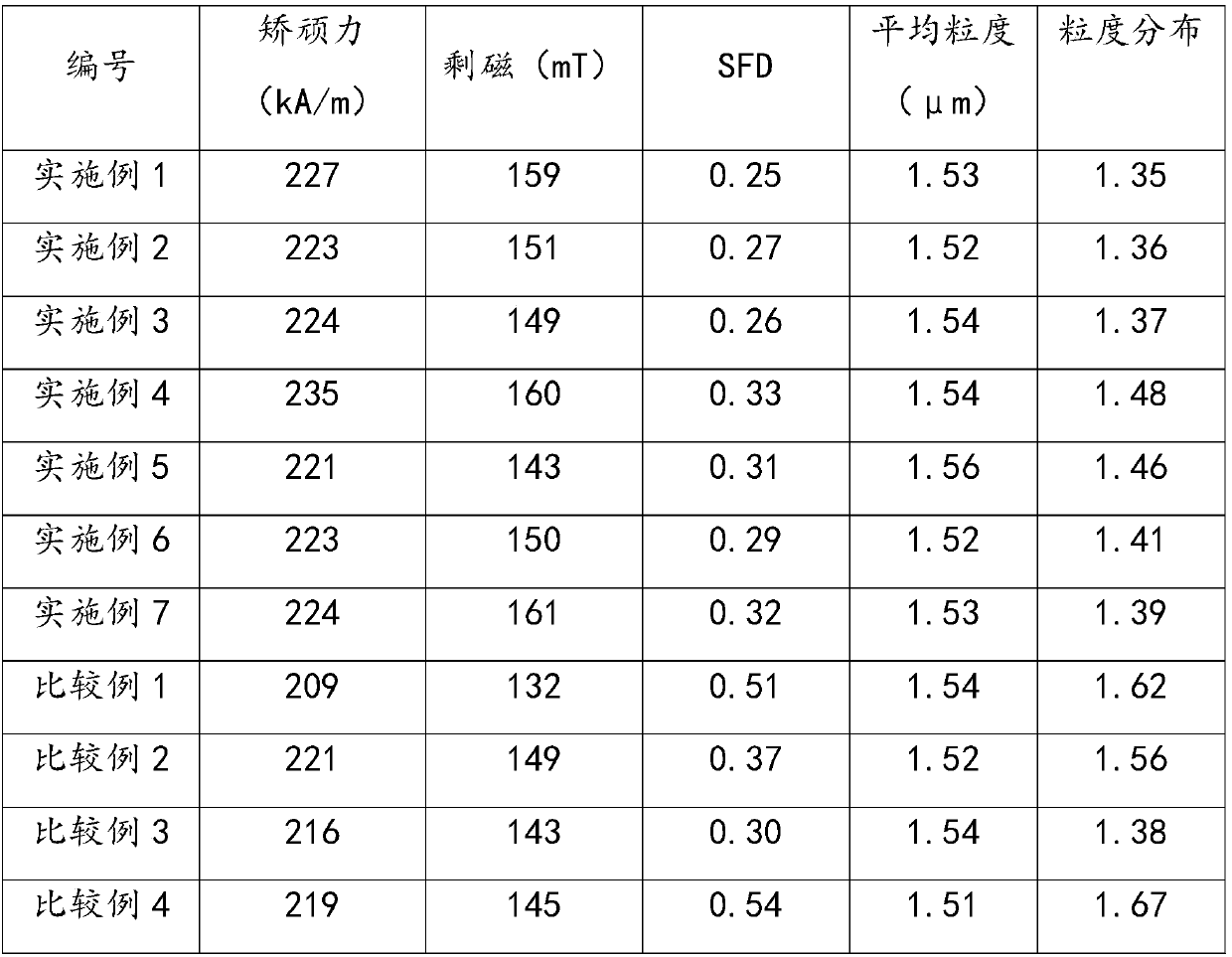

Examples

preparation example Construction

[0058] The present invention also provides a kind of preparation method of the magnetic recording material of described low SFD, comprises the steps:

[0059] The raw materials are mixed in proportion, densified, pre-fired at 1000-1200° C. for 1-4 hours, coarsely crushed and finely ground, and tempered at 920-1000° C. for 1-4 hours to obtain the magnetic recording material.

[0060] In a preferred embodiment of the present invention, the pre-calcination is carried out at 1000-1200° C. with gradient temperature increase for 1-4 hours. More preferably, pre-calcine at 1000-1050°C for 0.5-1h, raise the temperature to 1060-1100°C for 0.5-1h, and raise the temperature to 1150-1200°C for 0.5-2h.

[0061] In a preferred embodiment of the present invention, the densification treatment includes: using an ore mill for densification treatment for 30-90s.

[0062] In a preferred embodiment of the present invention, the size of the pelletized pellets is 50-500 μm.

[0063] In a preferred ...

Embodiment 1

[0067] The preparation method of the magnetic recording material described in the present embodiment, the steps are as follows:

[0068] (1) In parts by weight, weigh 135 parts of iron red (Tangshan Iron and Steel Group), 15 parts of strontium carbonate, 7 parts of barium carbonate, 1.5 parts of manganese oxide, 0.7 parts of niobium oxide, 1.2 parts of samarium oxide, and 1.2 parts of titanium oxide , 1.6 parts of cobalt oxide, 1.6 parts of zirconia, 1.6 parts of nickel oxide, and 2 parts of bismuth trioxide are mixed and placed in an ore mill. After densification treatment for 60 seconds, pellets are made with water, and the size of the pellets is 200 μm;

[0069] (2) Pre-burn the pellets obtained in step (1) at 1020°C for 0.5h, raise the temperature to 1080°C for 1h, and then raise the temperature to 1180°C for 1h; after the end, use a ball mill to perform coarse crushing to the average particle size 2.0 μm;

[0070] (3) placing the coarsely crushed material obtained in ste...

Embodiment 2

[0073] The present embodiment refers to the preparation method of Example 1, and the only difference is that the raw materials of this embodiment are 135 parts by weight of iron red (Tangshan Iron and Steel Group), 18 parts of strontium carbonate, 8 parts of barium carbonate, and 1.5 parts of manganese oxide. 0.7 parts of niobium oxide, 1.2 parts of samarium oxide, 1.2 parts of titanium oxide, 1.6 parts of cobalt oxide, 1.6 parts of zirconia, 1.6 parts of nickel oxide, and 2 parts of bismuth trioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com