Robot eyeball structure

A robot and eyeball technology, applied in the parts and electrical components of TVs and color TVs, etc., can solve the problems of blind spots of collection and limited application scenarios, and achieve the effect of simple structure and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

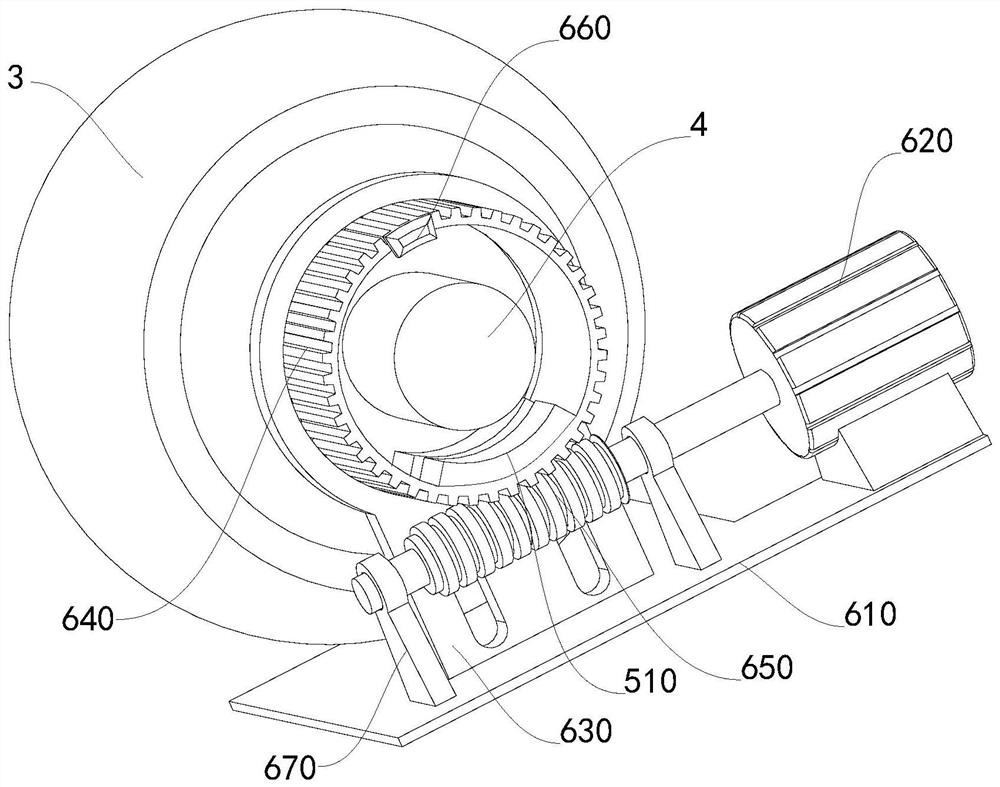

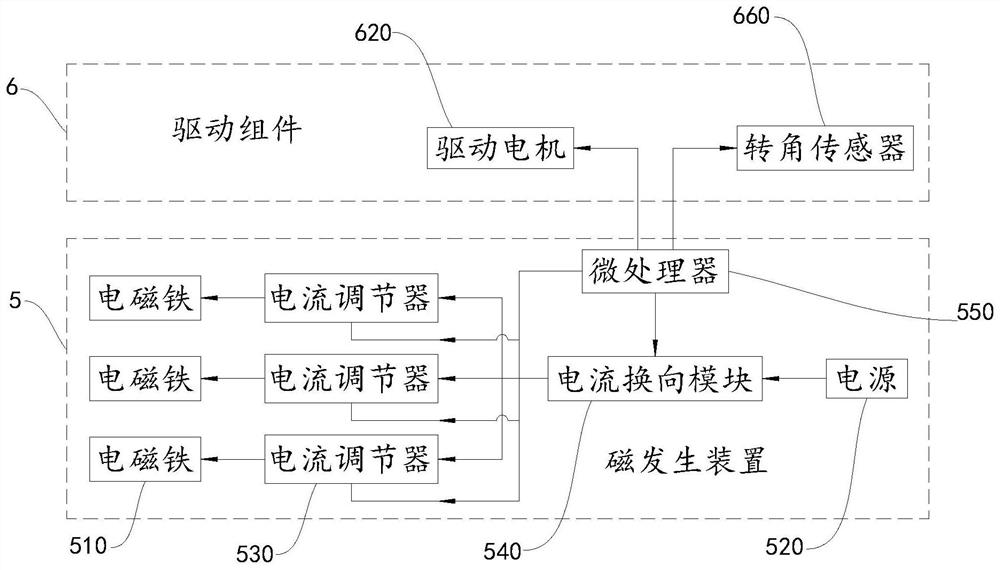

[0032] Such as Figure 1 ~ Figure 3 As shown, a robot eyeball structure includes an acquisition module 1, an eyeball 2, a ball socket 3, a magnetic column 4, a magnetic generating device 5, and a drive assembly 6. The eyeball 2 is movable in the ball socket 3, and the eyeball 2 and the ball socket 3 The cooperation is similar to that of a spherical hinge, the collection module 1 is arranged in the eyeball 2, and the collection module 1 is for video collection, image collection, etc., the type of the collection module 1 is not limited in the present invention, and it is enough to meet the use requirements according to actual needs; the magnetic column 4 is set at the tail end of the eyeball 2, and the axis line of the magnetic column 4 is in line with the axis line of the eyeball 2; the magnetic generating device 5 is set on the drive assembly 6, and driven by the drive assembly 6 to rotate around the magnetic column 4 .

Embodiment 2

[0034] Such as Figure 1 ~ Figure 3 As shown, the present embodiment is a further improvement on the basis of embodiment 1, specifically as follows:

[0035] Drive assembly 6 comprises base 610 and driving motor 620, and driving motor 620 is arranged on the base 610, and magnetic generator 5 is arranged on the output shaft of driving motor 620 eccentrically, and after driving motor 620 starts, will drive magnetic generator 5 to surround magnetic field. Column 4 rotates.

Embodiment 3

[0037] Such as Figure 1 ~ Figure 3 As shown, the present embodiment is a further improvement on the basis of embodiment 2, specifically as follows:

[0038] The driving assembly 6 also includes a fixed seat 630, a worm wheel 640 and a worm screw 650. The fixed seat 630 is arranged on the base 610. The worm wheel 640 is covered with the magnetic post 4. One end of the worm wheel 640 is rotationally connected with the fixed seat 630. Usually, the worm wheel 640 is connected to the fixed seat 630. Bearings are installed between the fixed seats 630 to ensure the accuracy and stability of the rotation through the bearings. The worm 650 is meshed with the worm wheel 640, and one end of the worm 650 is connected to the output shaft of the drive motor 620; the magnetic generator 5 is arranged on the worm wheel 640. In the inner circle, the distance between the magnetic column 4 and the magnetic generating device 5 is such that no matter which direction the magnetic column 4 deflects,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com