Preparation method of permeable concrete

A technology of permeable concrete and diatomite, applied in ceramic products, physical treatment, textiles and papermaking, etc., can solve the problems of low freeze-thaw resistance, poor workability of concrete, and inability to meet the requirements of drainage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

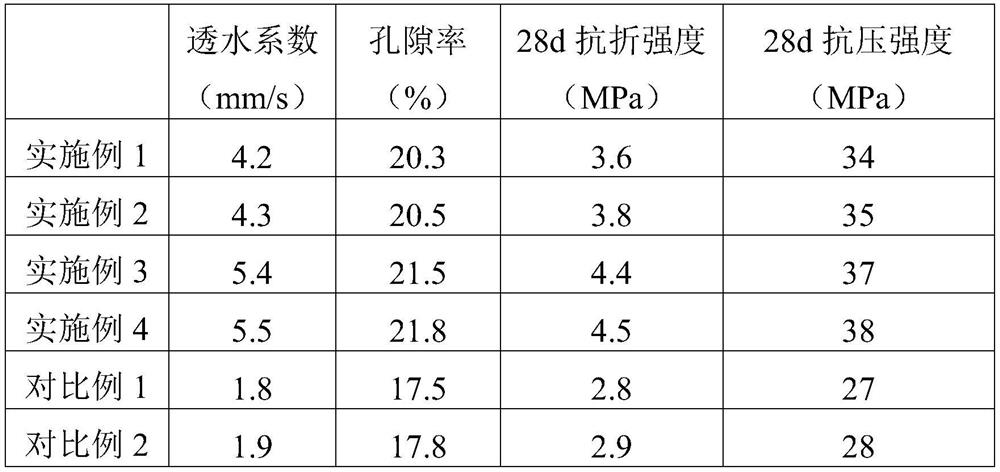

Examples

Embodiment 1

[0023] A preparation method of permeable concrete, comprising the following steps:

[0024] Step 1. Add 20 parts of nano-silica, 25 parts of hydroxypropyl methylcellulose, 20 parts of water reducer, 15 parts of dispersant, 12 parts of air-entraining agent, and 10 parts of early strength agent into the mixer in parts by weight. , 200 parts of water, stir and mix evenly;

[0025] Step 2. Send 1500 parts of gravel, 350 parts of cement, 80 parts of fly ash, 120 parts of polymer hollow reinforcing fiber, 50 parts of diatomaceous earth, and 10 parts of silica fume to the mixer, and stir at a stirring speed of 120r / min Mix evenly to obtain permeable concrete;

[0026] Wherein, the preparation method of the polymer hollow reinforcing fiber is as follows: preparing polymer solution I with a concentration of 6wt% and polymer solution II with a concentration of 8wt%; using polymer solution I as the core layer solution, and using polymer solution II as Shell solution, inject the core so...

Embodiment 2

[0032] A preparation method of permeable concrete, comprising the following steps:

[0033] Step 1. Add 15 parts of nano-silica, 20 parts of hydroxypropyl methylcellulose, 18 parts of water reducer, 12 parts of dispersant, 10 parts of air-entraining agent, and 8 parts of early-strength agent into the mixer in parts by weight. , 180 parts of water, stir and mix evenly;

[0034] Step 2. Send 1600 parts of gravel, 400 parts of cement, 75 parts of fly ash, 100 parts of polymer hollow reinforcing fiber, 45 parts of diatomaceous earth, and 10 parts of silica fume to the mixer, and stir at a stirring speed of 120r / min Mix evenly to obtain permeable concrete;

[0035]Wherein, the preparation method of the polymer hollow reinforcing fiber is: preparing a polymer solution I with a concentration of 5wt% and a polymer solution II with a concentration of 7wt%; using the polymer solution I as the core layer solution, and using the polymer solution II as the Shell solution, inject the core...

Embodiment 3

[0041] A preparation method of permeable concrete, comprising the following steps:

[0042] Step 1. Add 20 parts of nano-silica, 25 parts of hydroxypropyl methylcellulose, 20 parts of water reducer, 15 parts of dispersant, 12 parts of air-entraining agent, and 10 parts of early strength agent into the mixer in parts by weight. , 200 parts of water, stir and mix evenly;

[0043] Step 2. Send 1500 parts of gravel, 350 parts of cement, 80 parts of fly ash, 120 parts of polymer hollow reinforcing fiber, 50 parts of diatomite-loaded chitosan, and 10 parts of silica fume to the mixer at 120r / min Stir and mix evenly at a certain stirring speed to obtain permeable concrete;

[0044] Wherein, the preparation method of the polymer hollow reinforcing fiber is as follows: preparing polymer solution I with a concentration of 6wt% and polymer solution II with a concentration of 8wt%; using polymer solution I as the core layer solution, and using polymer solution II as Shell solution, inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com