Metal product punching method, metal product, metal plastic combined product and terminal

A product, a metal technology, applied in the terminal field, can solve the problems of unsatisfactory quality, affecting the reliability of metal-plastic combination products, etc., and achieve the effect of reducing the probability of separation of rubber and iron, strong pulling force, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

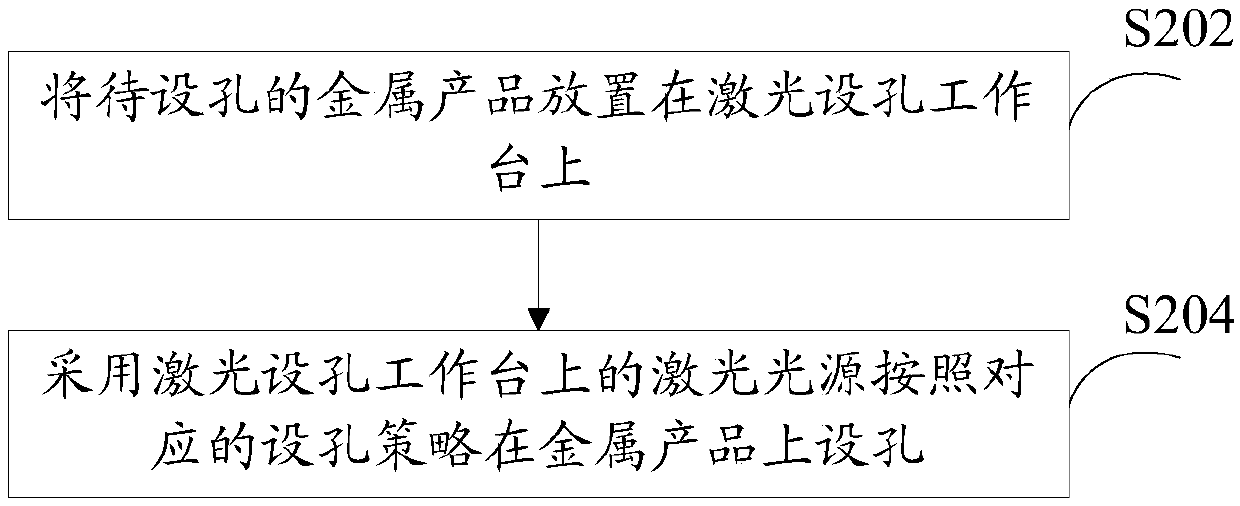

[0030] In related technologies, metal punching tools are usually used to set holes for rubber pulling on metal products. The metal punching tools use the principle of metal stamping to punch out holes on metal products. However, the holes set in this way have the following defect:

[0031] 1. The hole wall is smooth and the glue pulling force is not strong, which is prone to the problem of separation of plastic materials and metal products, which reduces the reliability of metal-plastic combined products;

[0032] 2. Since the holes are set by the metal punching tool, in order to ensure the strength of the metal punching tool, the metal punching tool should not be too thin, for example, the diameter of the metal punching tool should not be less than 0.5mm; this results in punched holes The diameter of the hole is greater than 0.5mm; in this case, if the diameter of the plastic injected into the hole is less than 0.5mm, after the metal-plastic combination product is applied to ...

Embodiment 2

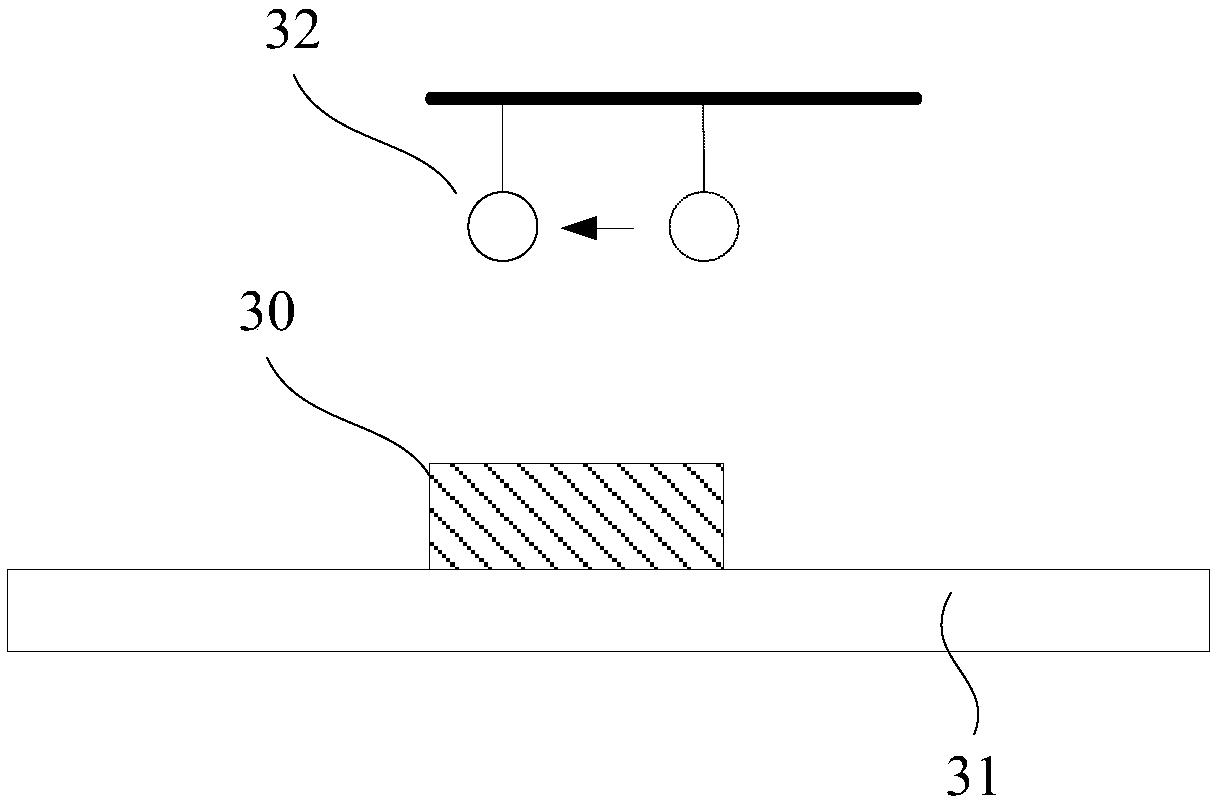

[0051] This embodiment provides a metal product. In some examples, the so-called metal product may be a hardware product. The "hardware product" in this embodiment refers to a product made of gold, silver, copper, iron, and tin alone or in combination. In this example, if Figure 5 and Figure 6 ( Figure 5 shows a top view of the metal product 50, while Figure 6 shown Figure 5 As shown in the schematic cross-sectional view of the metal product 50 along AA'), the metal product 50 includes at least one hole 51, which is used to accommodate the plastic material flowing into it during the injection molding stage, and the plastic material in the inflow hole is solidified Finally, the combination of the plastic material and the metal product is realized, that is, the hole is a hole for pulling glue. Therefore, the metal product is a raw material for manufacturing metal-plastic combined products.

[0052] In this embodiment, the hole 51 on the metal product 50 is set with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com