Waterborne anti-corrosion coating method for hot-galvanized U-shaped pre-buried channel and fitting

A technology of pre-embedded channels and coating methods, which is applied in the chemical field, can solve problems such as poor performance and serious environmental pollution by heavy metals, and achieve the effects of excellent impact resistance, no heavy metal pollution, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

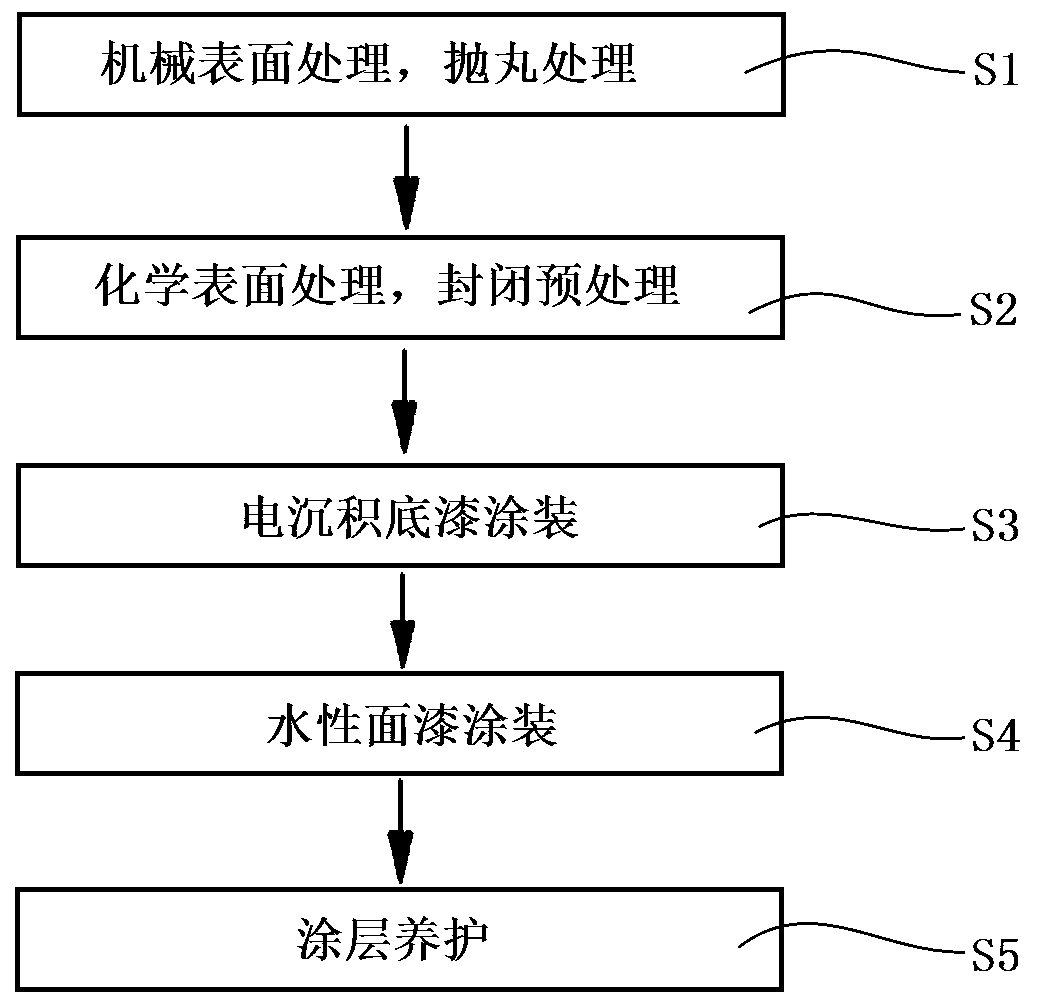

[0044] Apply water-based anti-corrosion coating to the hot-dip galvanized U-shaped embedded channel, the specific steps are as follows:

[0045] S1: Mechanical surface treatment, shot blasting treatment, select 150-mesh metal shot, enter the shot blasting machine by the method of passing through at 2000 speed, the shot blasting time is 0.1-15 minutes, remove all zinc slag, and make the surface The roughness reaches 10-25 microns;

[0046] S2: chemical surface treatment, use alkaline cleaning agent, spray for 1-3 minutes at 60-90 ℃, wash with water for 1-3 minutes, and then coat a layer of chromate-free passivation film, the coating temperature is 20-100 ℃, the coating time is 1-30 minutes, and the total film weight of the plated chromate-free passivation film is 0.2-10 grams per square meter;

[0047] S3: Electrodeposition primer coating, using epoxy cathodic electrodeposition coating, the composition is: resin 20%, resin includes epoxy, epoxy ester and polyurethane, pigment ...

Embodiment 2

[0051] Carry out water-based anti-corrosion coating on the pre-embedded channel support that has been hot-dip galvanized, and the specific steps are as follows:

[0052] S1: Mechanical surface treatment, shot blasting treatment, select 120-mesh metal shot material, adjust the speed by frequency conversion, let the shot material be thrown to the support at a speed of 30-60 m / s, and the shot blasting time is 0.1-15 minutes to remove all zinc slag Sag, make the surface roughness reach 10-25 microns;

[0053] S2: chemical surface treatment, use alkaline cleaning agent, spray for 1-3 minutes at 60-90 ℃, wash with water for 1-3 minutes, and then coat a layer of chromate-free passivation film, the coating temperature is 20-100 ℃, the coating time is 1-30 minutes, and the total film weight of the plated chromate-free passivation film is 0.2-10 grams per square meter;

[0054] S3: Electrodeposition primer coating, using epoxy cathodic electrodeposition coating, the composition is: res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com