A method for on-site horizontal assembly of steel pipe arches

A steel tube arch, on-site technology, applied in construction, bridge construction, bridges, etc., can solve the problems of high-altitude alignment risk, inaccurate alignment, poor control accuracy, etc., to achieve fast adjustment speed, less space, and stress prevention. concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

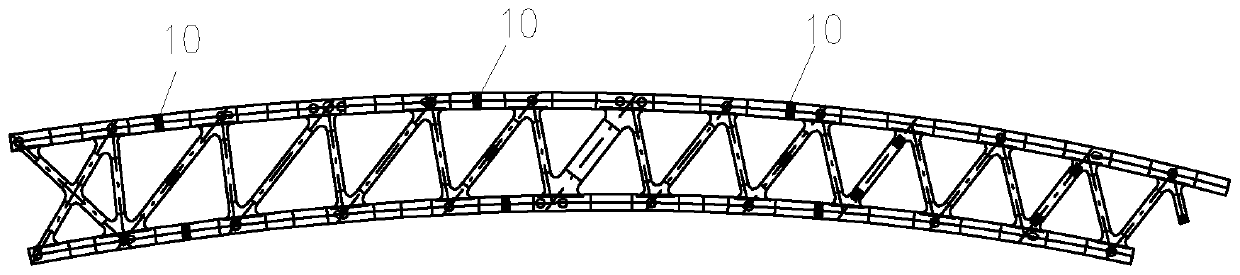

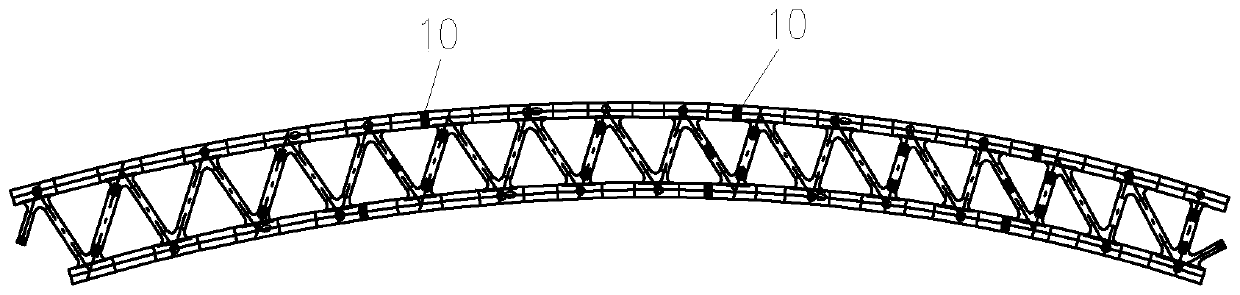

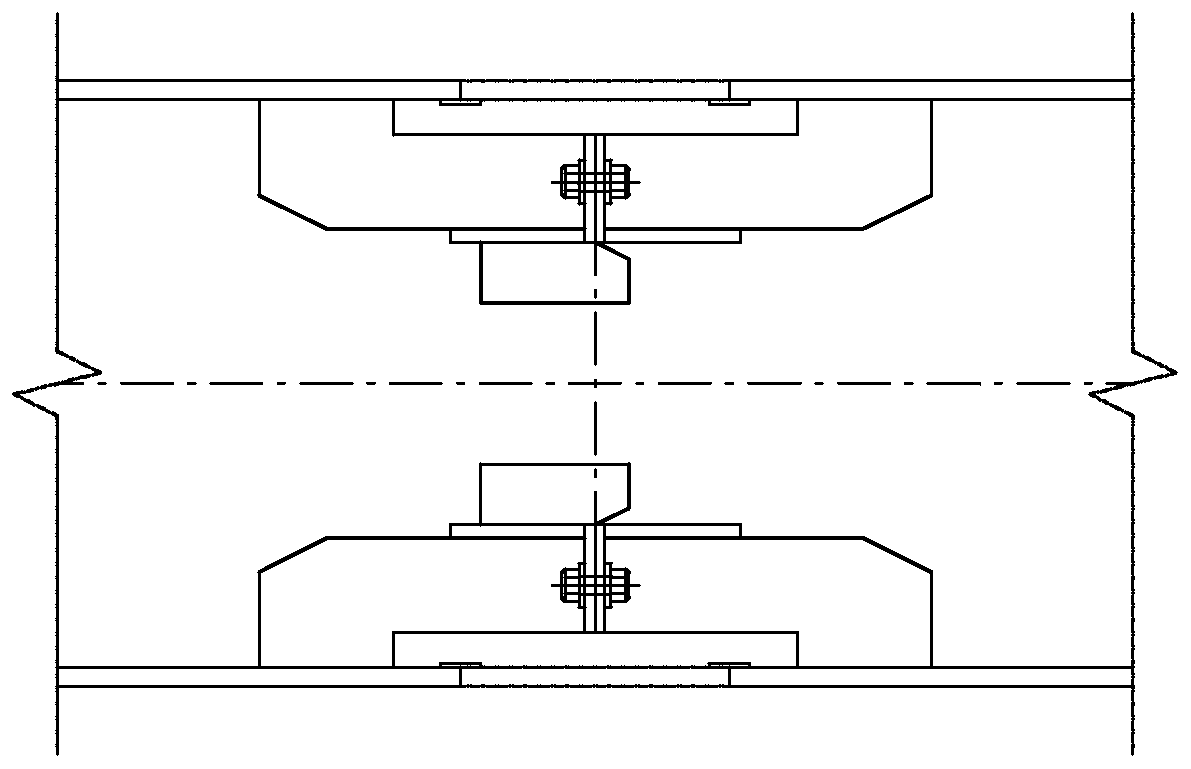

[0033] Please check Figure 1 to Figure 3 , a method for on-site horizontal assembly of steel pipe arches. In order to facilitate the management of steel components and consider the requirements of the construction site, component unit processing and group management are carried out in separate factories. The component units are processed and manufactured in the rear processing plant. Transport to the site for horizontal assembly and welding.

[0034] The component units transported to the site shall be checked and accepted item by item, compared, stacked and taken as required, and installed in strict accordance with the design.

[0035] The chord unit of the arch rib segment is connected by straight pipe, which is made by folding instead of bending. The length of the straight pipe is 1-3.6m. After passing the non-destructive test, it is rounded to ensure that the sagittal roundness of the pipe joint meets the requirements of the specification. The longitudinal butt welds bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com