Cleaning agent for laser holographic mould pressing plate

A technology of laser holography and embossed plate, which is applied in the direction of detergent compounding agent, detergent composition, surface active detergent composition, etc., can solve the problems of nickel plate darkening, incomplete cleaning, and difficulty in clearing, and achieve cleaning The effect of high efficiency, cost saving and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of this cleaning agent is also provided in the present embodiment, including:

[0030] 1) According to the scope of the above-mentioned mass ratio, weigh all the raw materials according to the proportioning;

[0031] 2) Dissolve detergent builders, solubilizers, nonionic surfactants, and gemini surfactants in an appropriate amount of deionized water, preferably to form a uniform solution;

[0032] 3) dissolving the defoamer and sodium edetate in the remaining deionized water prepared in step 2);

[0033] 4) Add the dissolved detergent builder, solubilizer, nonionic surfactant, and gemini surfactant in sequence to deionized water containing defoamer and sodium edetate, and stir evenly to obtain the Laser holographic embossed plate cleaning agent.

[0034] The surfactant that adopts in the present embodiment is nonionic surfactant and gemini surfactant compound and forms, makes the overall performance of surfactant better, especially the adoption ...

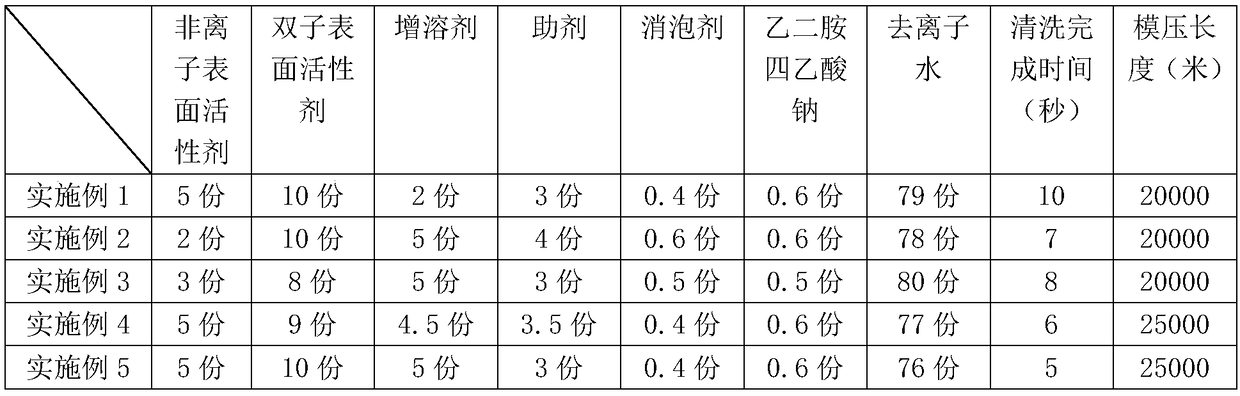

Embodiment 1

[0041] A cleaning agent for laser holographic stamping plates, using the following components in parts by weight: 5 parts of nonionic surfactants, 10 parts of gemini surfactants, 2 parts of solubilizers, 3 parts of auxiliary agents, 0.4 parts of defoamers, 0.6 part of sodium edetate, 79 parts of deionized water.

Embodiment 2

[0043] A cleaning agent for laser holographic stamping plates, using the following components in parts by weight: 2 parts of nonionic surfactants, 10 parts of gemini surfactants, 5 parts of solubilizers, 4 parts of auxiliary agents, 0.6 parts of defoamers, 0.4 part of sodium edetate, 78 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com