High-strength hydraulic-pressure-resistant polyethylene pipe and preparation method thereof

A polyethylene pipe, hydrostatic technology, applied in the direction of tubular objects, other household appliances, applications, etc., can solve the performance can not fully meet the actual use requirements of polyethylene pipes, the uneven cooling rate of the inner and outer walls of the pipe, the axial strength of the polymer pipe Advanced problems, to achieve the effect of easy to master control, improve hoop strength and hydrostatic resistance performance, high quality competitive advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

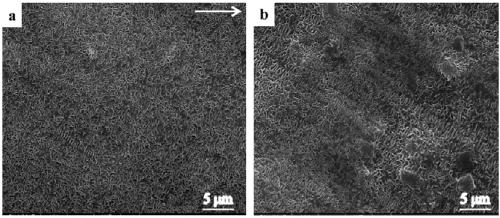

Image

Examples

Embodiment 1

[0043] First put 99.9 parts by weight of conventional polyethylene PE80 material (brand: HE3440, manufacturer: Borealis Chemicals) and 0.1 part by weight of micro-crosslinked polyethylene with a gel content of 1% into a high-mixer for 5 minutes, then place in the polymer In the tube rotary extrusion device, the mandrel and the die are rotated in reverse at the same time, at a speed of 1 rpm, the temperature of the melting section is 170°C, and the temperature of the die section is 180°C. Under the traction of the machine, the PE80 pipe with a pipe diameter of ¢110 is obtained by cooling and sizing.

[0044] The hoop strength of the obtained pipe under hydrostatic pressure at 20°C is 10.8MPa, and the hoop strength under hydrostatic pressure at 80°C is 5.52MPa, both of which are 120% of the standard failure pressure of PE80 pipe at this temperature; the corresponding failure times are respectively 105 hours and 170 hours, which are 105% and 103% of the standard failure time of P...

Embodiment 2

[0046] In this example, except that the conventional polyethylene is 93.0 parts by weight, the slightly cross-linked polyethylene is 7.0 parts by weight, the gel content is 30%, the rotating speed is 20 rpm, the temperature of the melting section is 270°C, and the temperature of the die section is 250°C. It is exactly the same as Example 1, so it is omitted.

[0047] The hoop strength of the obtained pipe under hydrostatic pressure at 20°C is 10.8MPa, and the hoop strength under hydrostatic pressure at 80°C is 5.52MPa, both of which are 120% of the standard failure pressure of PE80 pipes at corresponding temperatures; the corresponding failure times are respectively It is 107 hours and 168 hours, which are 107% and 102% of the standard destruction time of PE80 pipe at the corresponding temperature.

Embodiment 3

[0049] In this example, except that the conventional polyethylene is 95 parts by weight, the slightly cross-linked polyethylene is 5 parts by weight, the gel content is 4%, the rotating speed is 15 rpm, the temperature of the melting section is 205°C, and the temperature of the die section is 225°C, because the other It is exactly the same as Example 1, so it is omitted.

[0050] The hoop strength of the obtained pipe under hydrostatic pressure at 20°C is 11MPa, and the hoop strength under hydrostatic pressure at 80°C is 5.6MPa, both of which are 122% of the standard failure pressure of PE80 pipe at the corresponding temperature; the corresponding failure times are 118 hours and 194 hours are both 118% of the standard failure time of PE80 pipes at corresponding temperatures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hoop strength | aaaaa | aaaaa |

| Hoop strength | aaaaa | aaaaa |

| Hoop strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com