Novel high-efficiency paper enhancer

A paper reinforcing agent and high-efficiency technology, which is applied in the preparation of new high-efficiency paper reinforcing agent, in the field of papermaking with high-efficiency reinforcing agent, can solve the problems of poor secondary fiber strength, increased papermaking cost, and poor paper machine white water system, etc. To achieve the effect of improving adsorption and improving paper strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

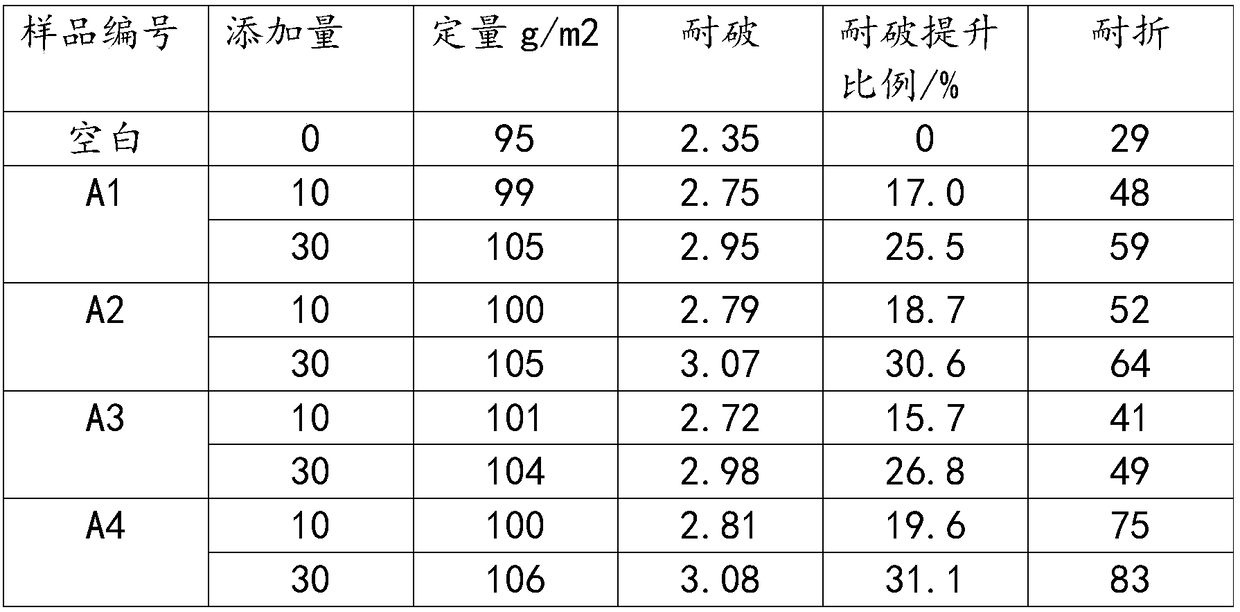

Examples

specific Embodiment example 1

[0025]In a 1L three-neck flask equipped with a stirrer, a thermometer, a reflux condenser, a constant pressure dropping funnel, and a nitrogen gas introduction tube, add 147 g of deionized water, and dissolve 200 g of acrylamide (30% aqueous solution) with 3 g of sulfuric acid (50% concentration). ), 28.5g (60% aqueous solution) methacryloxyethyltrimethylbenzyl ammonium chloride, 6.85g itaconic acid, 1.64g N-methylolacrylamide, 0.07g sodium hypophosphite, 3g polyvinylamine Adjust the pH of the mixed monomer (I) to 3, start stirring, feed nitrogen, and start to heat up. When the temperature reaches 80°C, add 0.7g ammonium persulfate. When the temperature reaches 88-90°C, start cooling and control the temperature Not exceeding 100°C, when the temperature is stable at 88-90°C, after reacting for 15 minutes, add 4g of sulfuric acid (50% content) dropwise to the reaction kettle to adjust PH=3.0, 60g of acrylamide (30% aqueous solution), 7g of deionized water , 16g (60% aqueous solu...

specific Embodiment example 2

[0027] In a 1L three-necked flask equipped with a stirrer, a thermometer, a reflux condenser, a constant pressure dropping funnel, and a nitrogen gas inlet tube, add 159 g of deionized water, and dissolve 200 g of acrylamide (30% aqueous solution) with 3 g of sulfuric acid (50% concentration). ), 28.5g (60% aqueous solution) methacryloxyethyltrimethylbenzyl ammonium chloride, 6.85g itaconic acid, 1.64g N-methylolacrylamide, 0.07g sodium hypophosphite, polyvinylamine 6.0 The pH of the mixed monomer (I) of g is adjusted to 3, and the stirring is started, nitrogen gas is introduced, and the temperature starts to rise. When the temperature reaches 80°C, add 0.7g of ammonium persulfate, and when the temperature reaches 88-90°C, start cooling and control The temperature does not exceed 100°C. When the temperature is stabilized at 88-90°C, after 15 minutes of reaction, add 4g of sulfuric acid (50% content) dropwise to the reactor to adjust 68g of acrylamide (30% aqueous solution) and ...

specific Embodiment example 3

[0029] In a 1L three-necked flask equipped with a stirrer, a thermometer, a reflux condenser, a constant pressure dropping funnel, and a nitrogen inlet tube, add 153 g of deionized water, and dissolve 254 g of acrylamide (30% aqueous solution) with 3 g of sulfuric acid (50% concentration). ), 9.5g (60% aqueous solution) methacryloyloxyethyltrimethylbenzyl ammonium chloride, 2.6g itaconic acid, 1.1g N-methylolacrylamide, 0.005g sodium hypophosphite, polyvinylamine 12.0 The pH of the mixed monomer (I) of g is adjusted to 3, and the stirring is started, nitrogen gas is introduced, and the temperature starts to rise. When the temperature reaches 80°C, add 0.7g of ammonium persulfate, and when the temperature reaches 88-90°C, start cooling and control The temperature does not exceed 100°C. When the temperature is stable at 88-90°C, after 15 minutes of reaction, add 4g of sulfuric acid (50% content) dropwise to the reaction kettle to adjust pH=3.0, 60g of acrylamide (30% aqueous solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com