System and process for decomposing calcium sulfate and recovering sulfur and calcium oxide through carbon-sulfur cooperation

A technology of calcium sulfate and calcium oxide, which is applied in the system field of charcoal and sulfur synergistically decomposing calcium sulfate to recover sulfur and calcium oxide, can solve the problems of low-grade gypsum that is difficult to handle, reduce the dependence on external sulfur resources, etc., and achieve the realization of resources efficient utilization, saving resources, and alleviating the shortage of sulfur resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

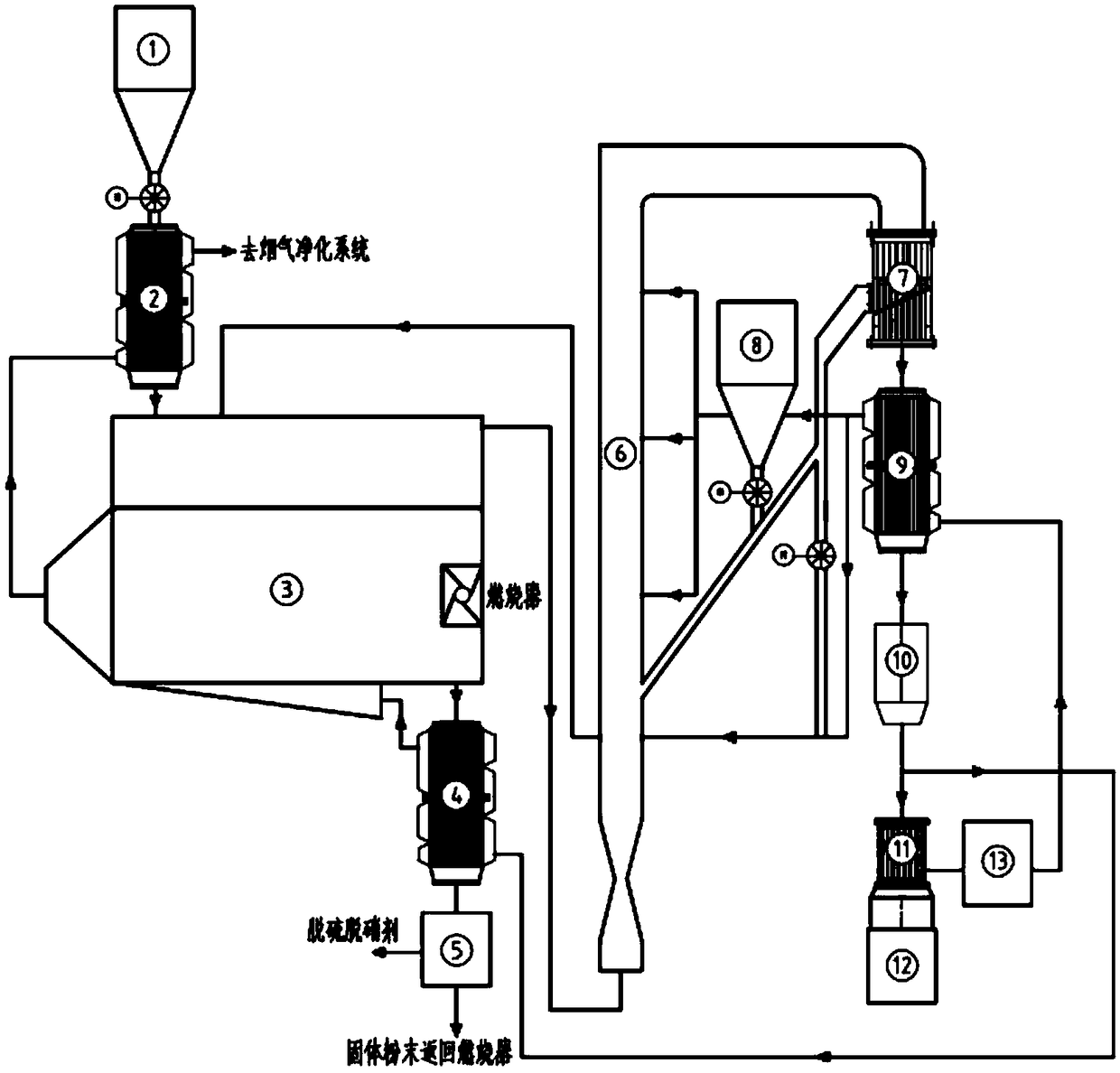

[0065] systems such as figure 1 As shown, it consists of calcium sulfate storage bin 1, calcium sulfate preheater 2, indirect heating decomposition furnace 3, roasted slag cooler 4, filter device 5, charcoal thermal reduction tower 6, high temperature separator 7, carbon material storage bin 8, Reheater 9, dedusting device 10, sulfur recovery device 11, sulfur storage tank 12, water vapor cooler 13.

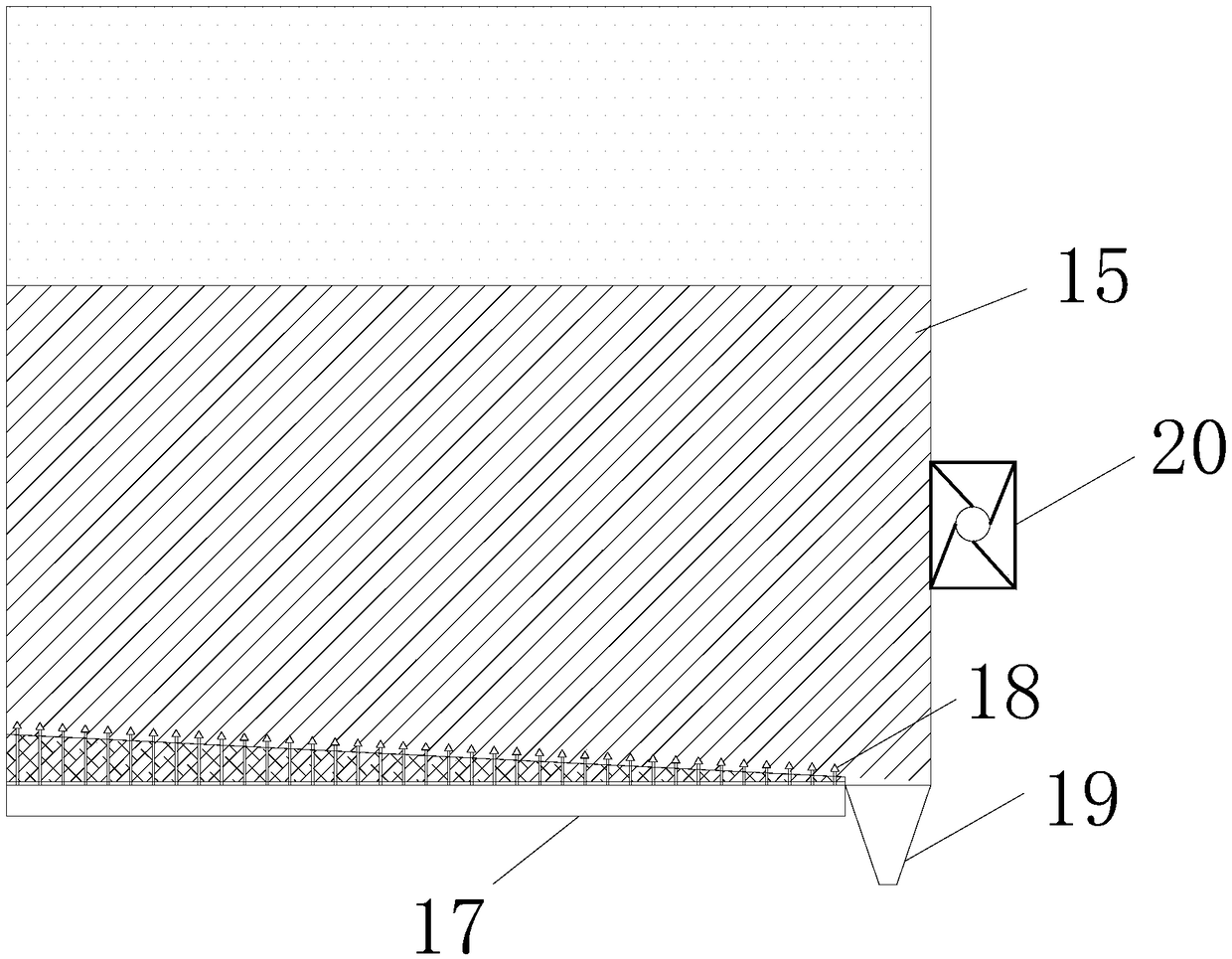

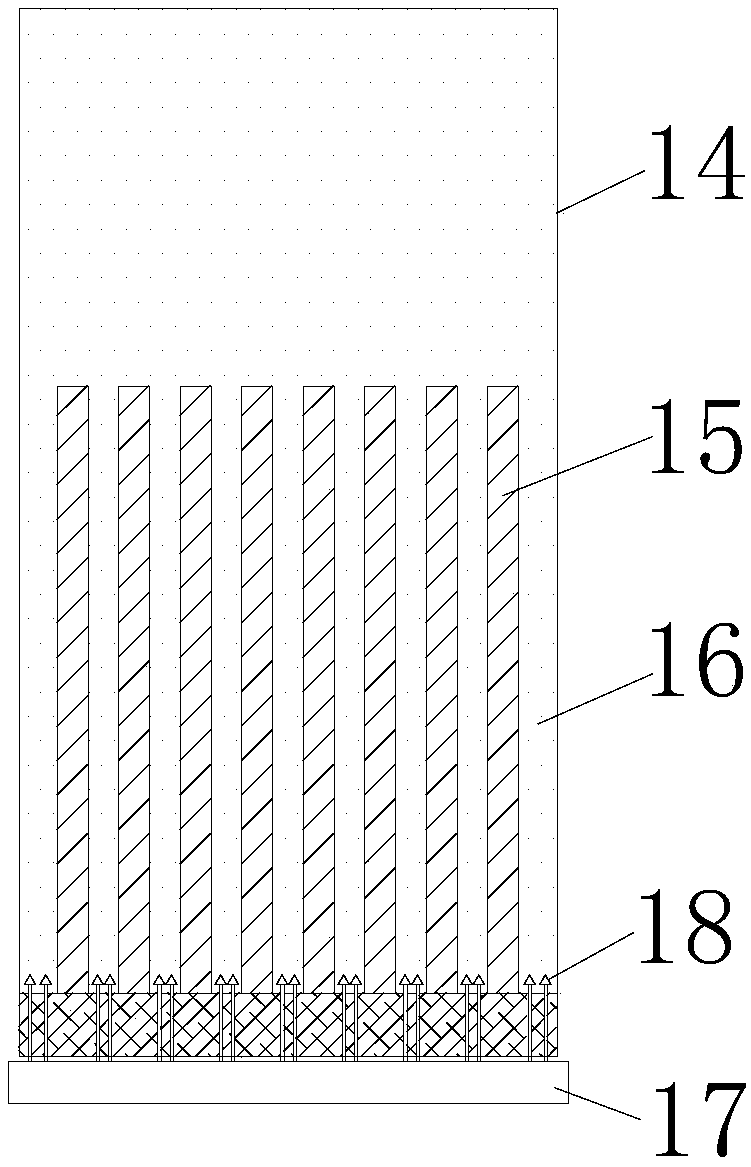

[0066] Among them, the indirect heating decomposition furnace, such as Figure 2~3 As shown, it consists of a housing 14, several flues 15 and a burner. The flue 15 is arranged in the housing 14, and the flue 15 extends from the housing 14 to the outside of the housing 14. The flue 15 and the housing 14 The space between them forms a forehearth 16, the inlet of the flue 15 is connected to the flue gas outlet of the burner, and the material of the flue is ceramic. The burner is arranged at one end of the housing 14, and the bottom of the housing 14 is provided with an air duct 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com