Composite powder with heterogeneous core-shell structure and preparation method thereof

A technology of composite powder and core-shell structure, used in metal processing equipment, coating, transportation and packaging, etc. Complexity and other problems, to achieve the effects of cheap reaction raw materials, shortened production cycle, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

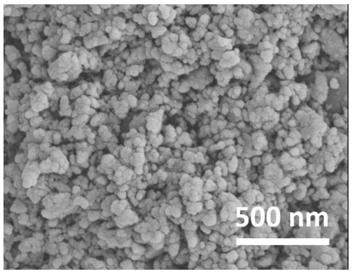

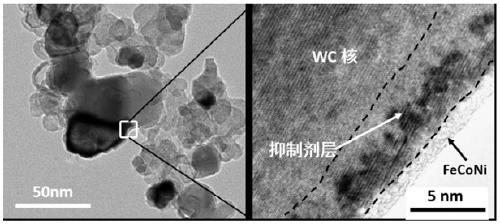

Image

Examples

Embodiment 1

[0026] A composite powder with a heterogeneous core-shell structure, with WC as the core, inhibitor VC as the inner shell, and FeCoNi alloy as the outer shell; the mass fraction of the inhibitor in the composite powder is 1.4wt.%, FeCoNi alloy The mass fraction in the composite powder is 10wt.%, and the mass ratio of Fe, Co, and Ni in the FeCoNi alloy is 1:2:1.

[0027] The preparation method of the above heterogeneous core-shell structure composite powder comprises the following steps:

[0028] (1) Weigh 50kg of ammonium paratungstate, 1kg of ammonium metavanadate, 4kg of cobalt oxalate, 2.3kg of ferric chloride, 2kg of nickel oxalate, glucose 41kg;

[0029] (2) Dissolve the ammonium paratungstate, ammonium metavanadate, cobalt oxalate, ferric chloride, nickel oxalate, and glucose in 250kg deionized water to prepare a solution, and carry out mixing treatment at 80°C for 10 minutes to obtain a mixed solution, and mix the mixed solution Transfer to a polytetrafluoroethylene-l...

Embodiment 2

[0032] A composite powder with heterogeneous core-shell structure, with WC as the core, inhibitors VC, Cr 3 C 2 is the inner shell layer, and the FeCoNi alloy is the outer shell layer; the mass fraction of the inhibitor in the composite powder is 1.8wt.%, and the mass fraction of the binder phase metal in the composite powder is 4.5wt.%. , The mass ratio of Fe, Co, and Ni in FeCoNi alloy is 1:1:2.

[0033] The preparation method of the above heterogeneous core-shell structure composite powder comprises the following steps:

[0034] (1) Weigh 53kg of ammonium metatungstate, 1kg of ammonium metavanadate, 0.5kg of ammonium dichromate, 2kg of iron oxalate, and acetic acid according to the composition of the heterogeneous core-shell composite powder. Cobalt 1.5kg, nickel acetate 3kg, sucrose 39.5kg;

[0035] (2) Dissolving the ammonium metatungstate, ammonium metavanadate, ammonium dichromate, ferric oxalate, cobalt acetate, nickel acetate, and sucrose in 300kg deionized water t...

Embodiment 3

[0038] A composite powder with heterogeneous core-shell structure, with WC as the core, inhibitors VC, Cr 3 C 2is the inner shell layer, FeCoNi alloy is the outer shell layer; the mass fraction of the inhibitor in the composite powder is 4wt.%, the mass fraction of the binder phase metal in the composite powder is 14wt.%, FeCoNi The mass ratio of Fe, Co and Ni in the alloy is 1:1:1.

[0039] The preparation method of the above heterogeneous core-shell structure composite powder comprises the following steps:

[0040] (1) Weigh 42kg of ammonium metatungstate, 3kg of ammonium molybdate, 8.3kg of iron oxalate, 5kg of cobalt oxalate, 5kg of nickel oxalate, 40kg of sucrose;

[0041] (2) The ammonium metatungstate, ammonium molybdate, iron oxalate, cobalt oxalate, nickel oxalate, and sucrose were dissolved in 250kg deionized water to prepare a solution, and mixed at 70°C for 20 minutes to obtain a mixed solution. The solution was transferred to a polytetrafluoroethylene-lined st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com