Method for removing biomass gasification pollutants by magnetically stabilized bed

A technology for magnetically stabilizing a bed and pollutants, which is applied in the field of biomass gasification pollutant treatment, can solve the problems of complex process, increase cost, etc., achieve high catalytic efficiency, improve service life, and inhibit the generation of bubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

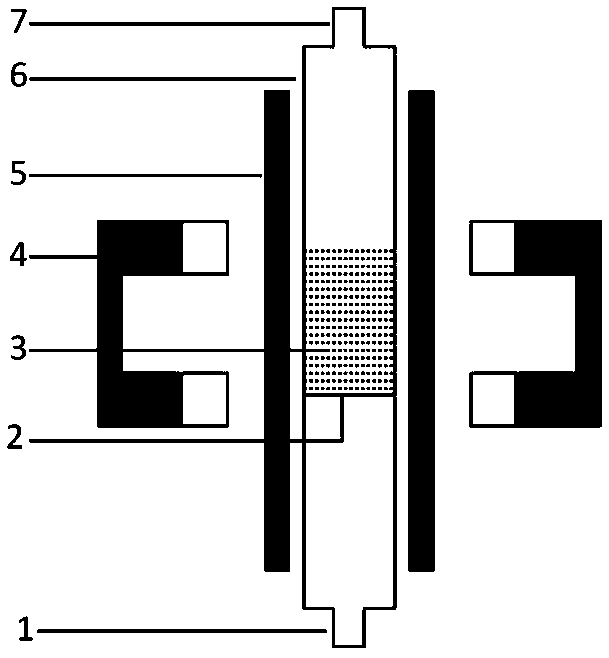

[0027] A method for removing biomass gasification pollutants by a magnetically stabilized bed of the present invention, comprising the steps of:

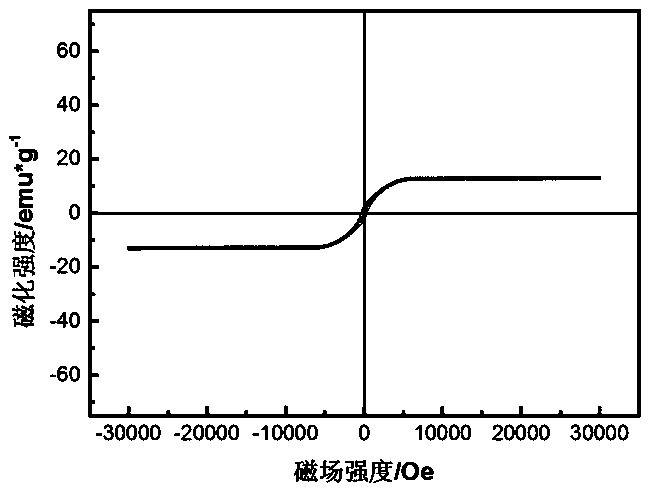

[0028] (1) Preparation of magnetic catalyst Co / γ-Al by impregnation method 2 o 3

[0029] Take 18g Co(NO 3 ) 2 •9H 2 O was adjusted to 20 mL with deionized water, and 3 mol / L Co(NO 3 ) 2 solution. Add about 20g of 0.63mm γ-Al 2 o 3 Immerse into it and let stand for 12h. Afterwards, the catalyst and the solution were separated into solid and liquid, and the solid was dried in an oven at 105 °C for 12 h. Finally, the dried catalyst was put into a muffle furnace from room temperature to 500°C at a rate of 10°C / min, and calcined at this temperature for 4 hours to obtain Co / γ-Al with a Co content of 15%wt. 2 o 3 Catalyst precursor, followed by hydrogen reduction to obtain Co / γ-Al 2 o 3 catalyst.

[0030] In the present invention, the particle size of the catalyst is controlled to be 0.6-0.65 mm, and studies have proved tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com