Flue gas treatment device for processing of ores

A technology of flue gas treatment and treatment equipment, which is applied in the field of ore processing, can solve problems such as ineffective treatment, and achieve the effects of avoiding work effects, improving service life, and reducing omissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

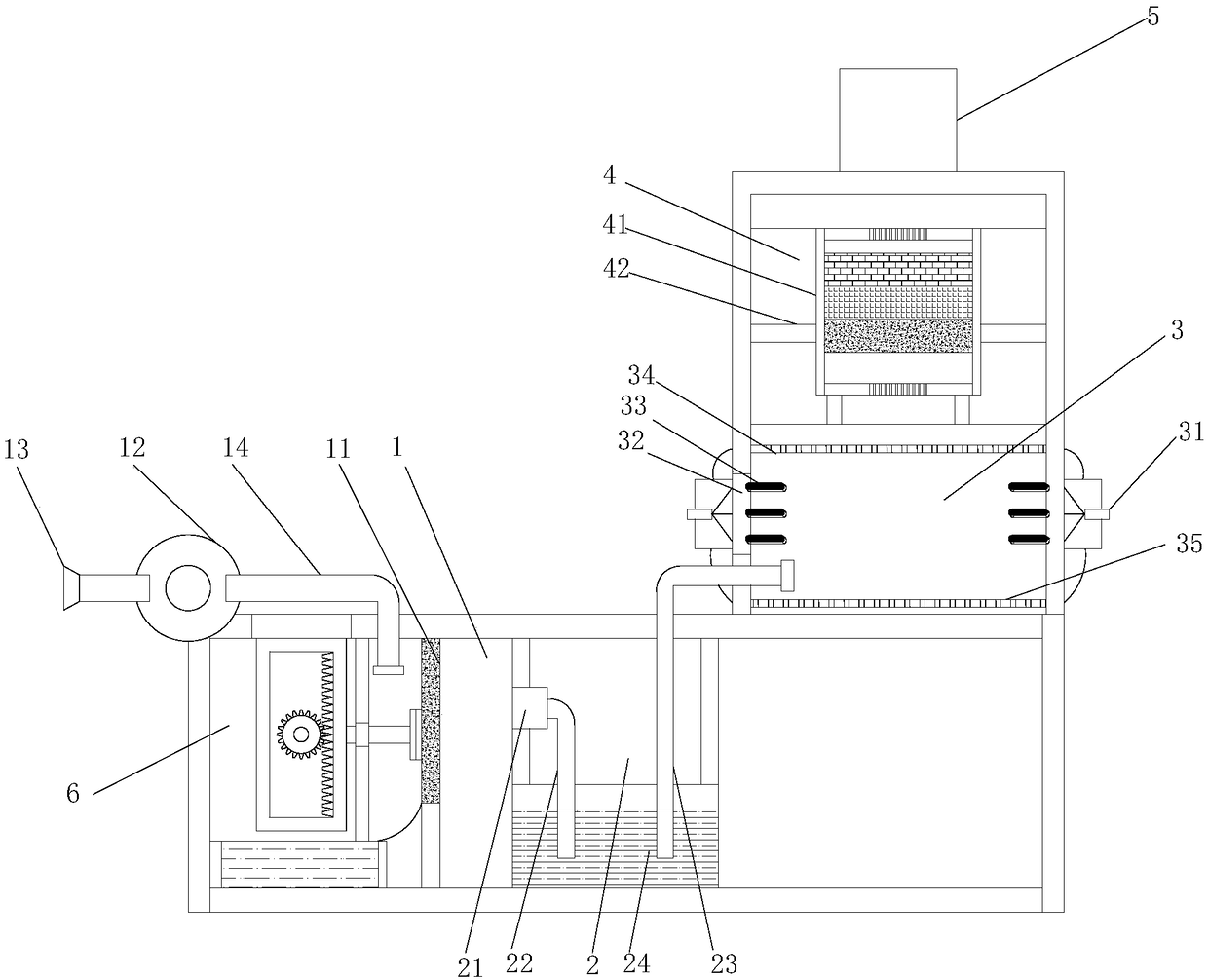

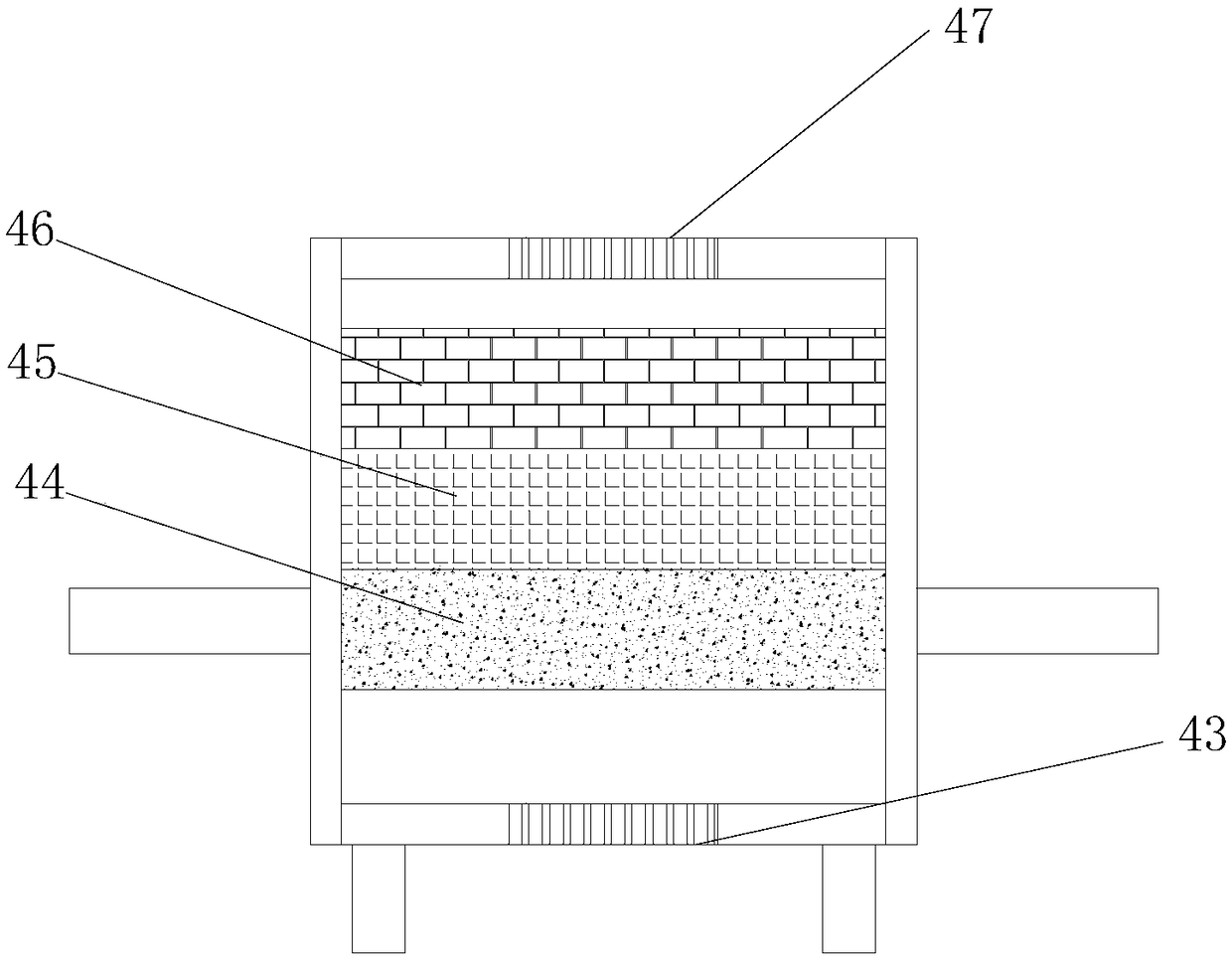

[0025] see figure 1 and figure 2 , a flue gas processing device for ore processing, the processing device is respectively provided with a filter chamber 1, a dedusting and desulfurization chamber 2, an electrostatic dedusting chamber 3, an adsorption processing chamber 4 and a chimney 5, the filter chamber 1 Filter sponge 11 is set, and described filter chamber 1 front end is provided with suction pump 12, and the air intake end of described suction pump 12 is equipped with suction funnel 13, and the air delivery end of suction pump 12 is equipped with air delivery pipe 14, so The bottom end of the air delivery pipe 14 extends into the front side of the filter sponge 11, and the filter sponge 11 performs preliminary filtering treatment on the smoke, and a large amount of dust in the smoke is intercepted and retained in the filter chamber 1.

[0026] The dust removal and desulfurization chamber 2 is located at the rear side of the filter chamber 1, and a drainage pump 21 is a...

Embodiment 2

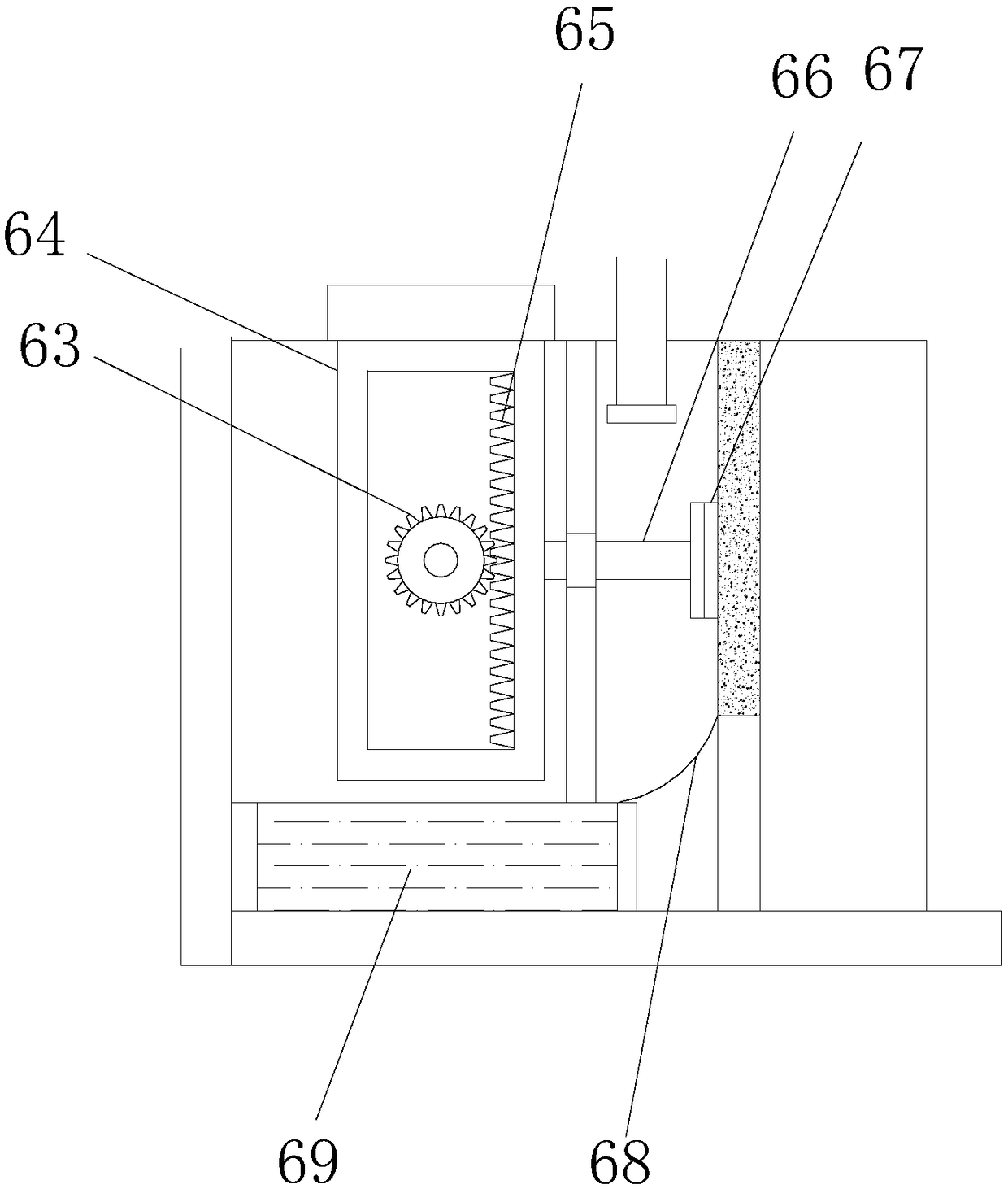

[0033] see image 3 and Figure 4, this embodiment is a further optimization of Embodiment 1. On the basis of it, a dust removal chamber 6 is provided on the front side of the inner chamber of the filter chamber 1, and a movable frame 64 is arranged in the dust removal chamber 6. The dust removal chamber 6 Transmission motor 61 is installed on the side wall of the transmission motor 61, and transmission gear 63 is installed on the driving end of the transmission motor 61 through the driving shaft 62. A rack 65 is provided, the transmission gear 63 is meshed with the rack 65, the rear end of the movable frame 64 is equipped with a fixed rod 66, and a dust wipe 67 is installed on the fixed rod 66, and the dust wipe 67 is connected to the fixed rod 66. The surfaces of the filter sponge 11 are attached to each other, and a diversion slope 68 is arranged under the filter sponge 11 , and a water tank 69 is installed at the end of the diversion slope 68 . A pulley is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com