Sizing percentage online regulation and control method based on yarn form change

A technology of shape change and yarn, applied in the direction of image data processing, measuring devices, instruments, etc., can solve the problems of control lag, detection equipment error of restricted detection conditions, and difficulty in satisfying actual production, etc., to achieve stable diameter and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

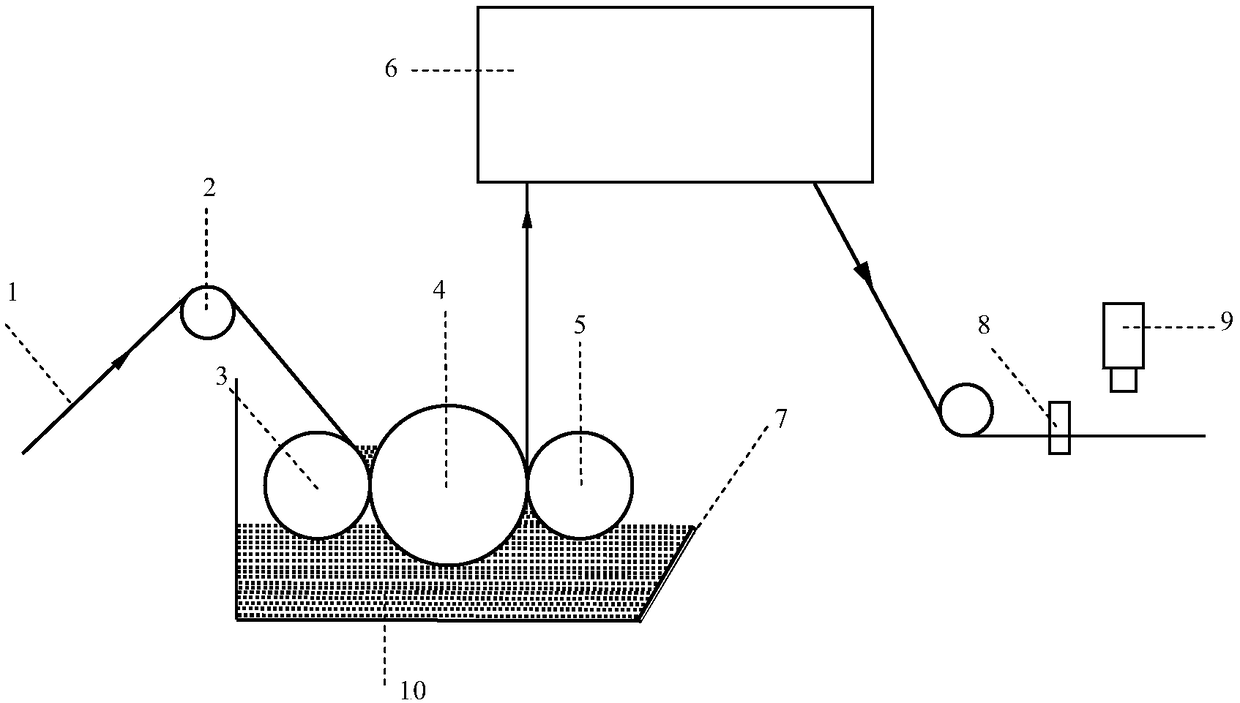

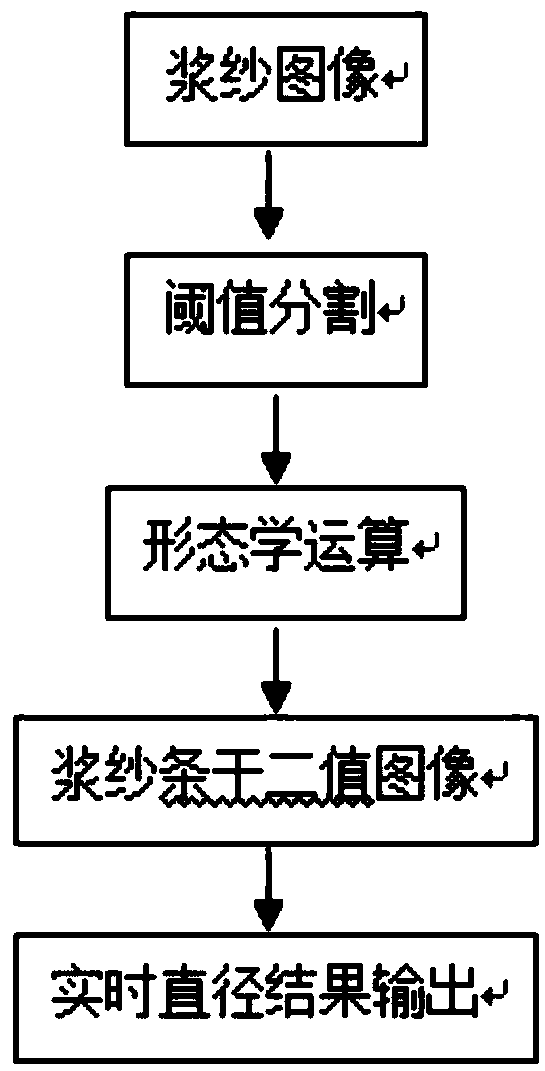

[0033] figure 1 It is the sizing process of the yarn 1. As shown in the figure, the yarn 1 is guided by the guide roller 2 and then enters the size solution 10 through the pre-press roller 3 and the sizing roller 4 for sizing, and then winds the sizing roller 4 to output the size solution 10, and passes through the high pressure The roller 5 removes excess size liquid 10 on the yarn 1, and then enters the drying room 6 for drying. After the drying is completed, it is drawn out and separated into single yarns through the reed, and the liquid blocking plate 7 is used to adjust the height of the size liquid 10. .

[0034] In this process, the online adjustment method of sizing rate based on the change of yarn shape is used to adjust the pressure force applied by the high pressure roller 5 on the sizing roller 4 online. The online adjustment method includes the following specific steps:

[0035] 1), such as figure 1 Shown, utilize camera 9 to collect the video image of the sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com