Novel water hose production method

A production method and water belt technology, applied in textile, application, coating and other directions, can solve the problems of easy knotting, reduced work efficiency, and the quality cannot be effectively improved, so as to improve the tensile strength and product quality. , the effect of high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

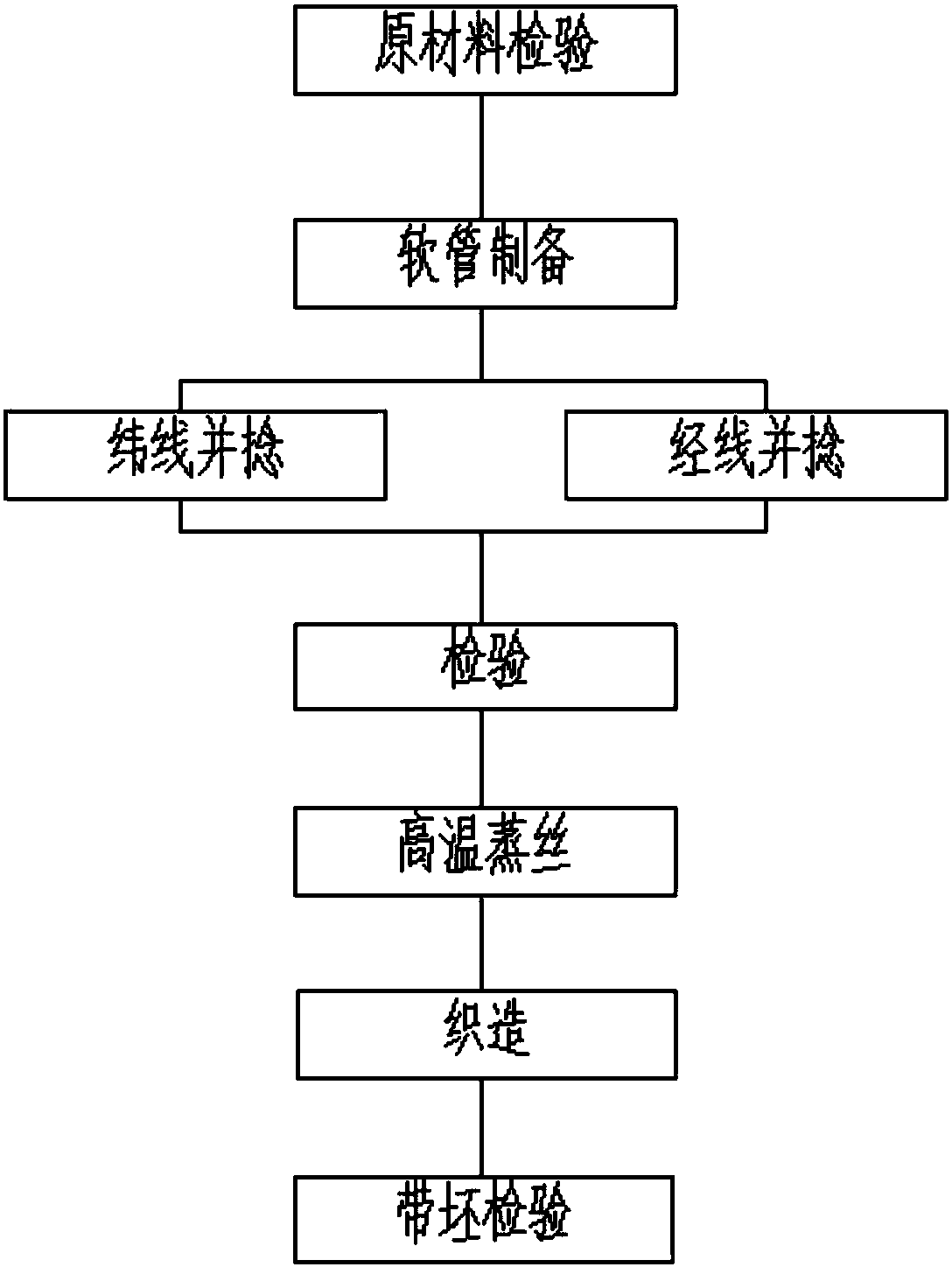

[0021] Embodiment 1: a kind of novel hose production method, concrete preparation method step is as follows:

[0022] Step 1: Use the equipment to inspect the raw materials of the lining hose and the braided fabric on the outer surface of the hose;

[0023] Step 2: The lining hose uses raw materials to directly extrude the hose with a cold-feed extruder;

[0024] Step 3: The warp and weft preparation process includes single yarn winding, splicing, twisting, and thread making. The staff uses the twisting machine to make polyester yarn through the twisting process into polyester yarn, and weaves warp and weft according to different materials as raw materials;

[0025] Step 4: Check the appearance and tensile elongation of the extruded hose of the cold feed extruder, and inspect the appearance and physical tensile strength of the warp and weft. The thickness of the extruded hose is uniform, the diameter is stable, and the glue The extrusion flow rate of the adhesive is stable, ...

Embodiment 2

[0034] Embodiment 2: a kind of novel hose production method, concrete preparation method step is as follows:

[0035] Step 1: Use the equipment to inspect the raw materials of the lining hose and the braided fabric on the outer surface of the hose;

[0036] Step 2: The lining hose uses raw materials to directly extrude the hose with a cold-feed extruder;

[0037] Step 3: The warp and weft preparation process includes single yarn winding, splicing, twisting, and thread making. The staff uses the twisting machine to make polyester yarn through the twisting process into polyester yarn, and weaves warp and weft according to different materials as raw materials;

[0038] Step 4: Check the appearance and tensile elongation of the extruded hose of the cold feed extruder, and inspect the appearance and physical tensile strength of the warp and weft. The thickness of the extruded hose is uniform, the diameter is stable, and the glue The extrusion flow rate of the adhesive is stable, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com