Intelligent cyclic flowing type erosion corrosion testing system and testing method

A technique for scouring corrosion and test systems, which is applied in the direction of testing wear resistance, weather resistance/light resistance/corrosion resistance, measuring devices, etc. It can solve the problem that the concentration, flow rate and temperature of corrosive media cannot be accurately controlled, and the test results cannot truly reflect industrial Actual working conditions, lack of influence of pipe erosion and corrosion characteristics, etc., to achieve the effect of improving safety and efficiency, convenient adjustment in the later stage, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

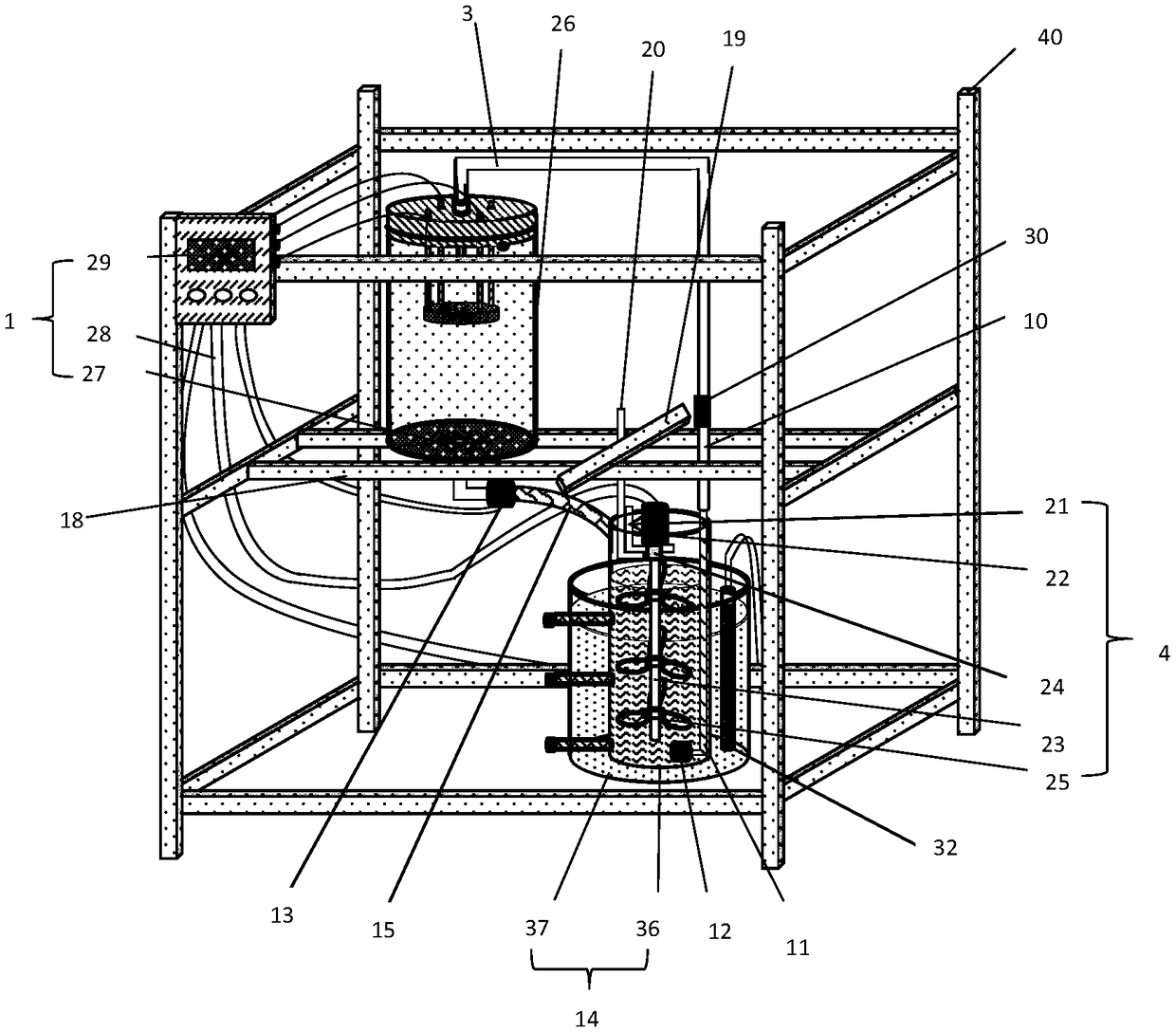

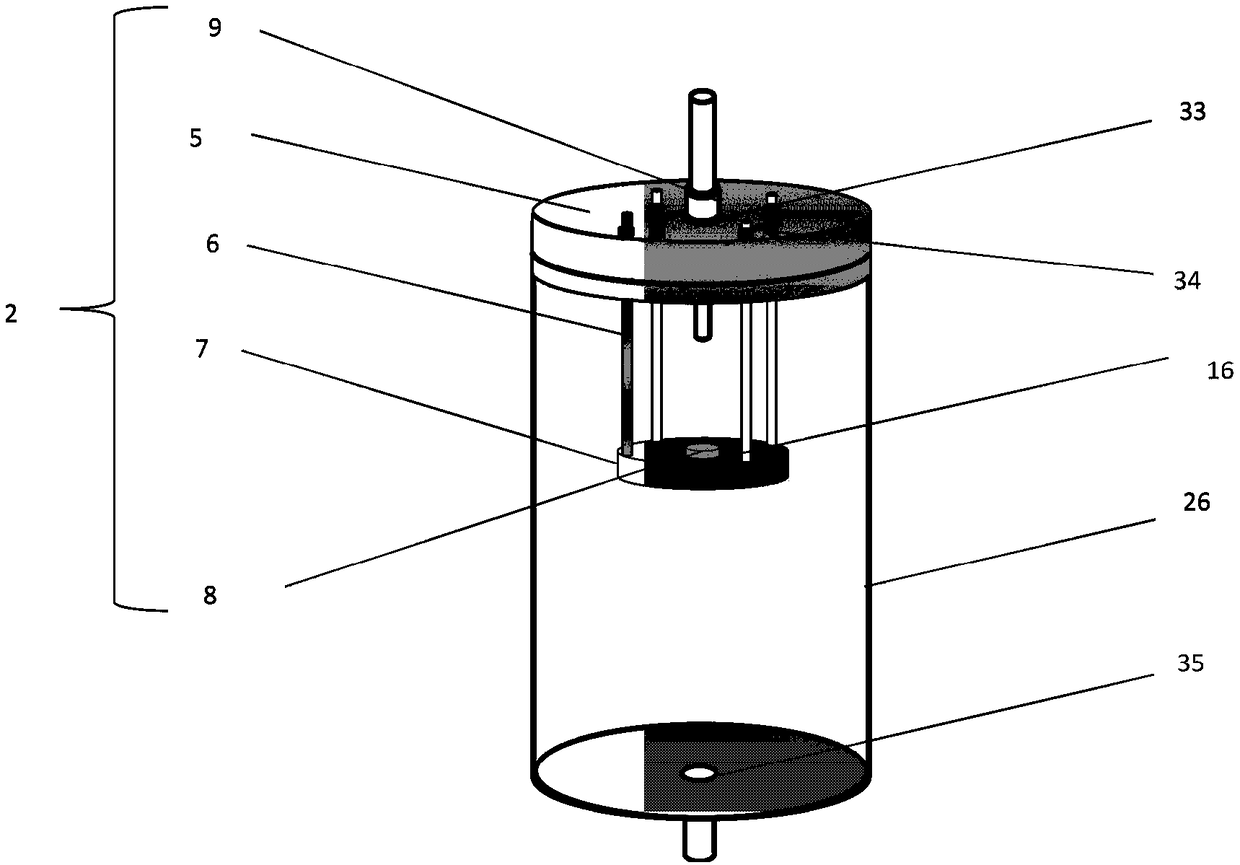

[0040] Such as figure 1 As shown, the present invention includes a frame 40, a temperature control system 1, a test piece erosion corrosion system 2, a test solution circulation system 3 and a test solution stirring system 4; the frame 40 is a cuboid structure, and the middle parts of both sides of the frame are fixed with and the two beams are located at the same height, two first guide rails 18 parallel to each other are slidably installed between the two beams, and the second guide rail 19 is slidably installed on the upper end surfaces of the two first guide rails 18 and perpendicular to the first guide rail 18, The third guide rail 20 is connected to the second guide rail 19 through a corner piece, and the third guide rail 20 is located between the two first guide rails 18 and arranged vertically to the ground.

[0041] The test solution stirring system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com