A non-ironing finishing method for pure cotton fabric

A pure cotton fabric, non-iron finishing technology, applied in the treatment of textile materials, spray/jet textile material treatment, plant fibers, etc. Breaking strength reduction and other problems, to achieve excellent anti-wrinkle effect, shorten the processing cycle, maintain the effect of color and luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

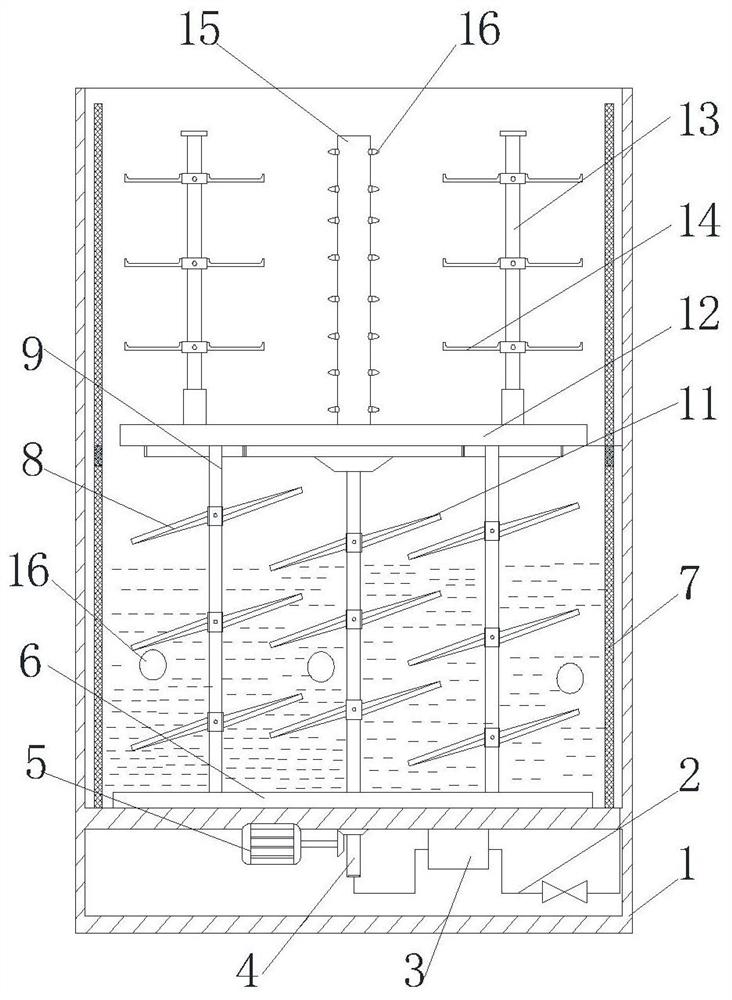

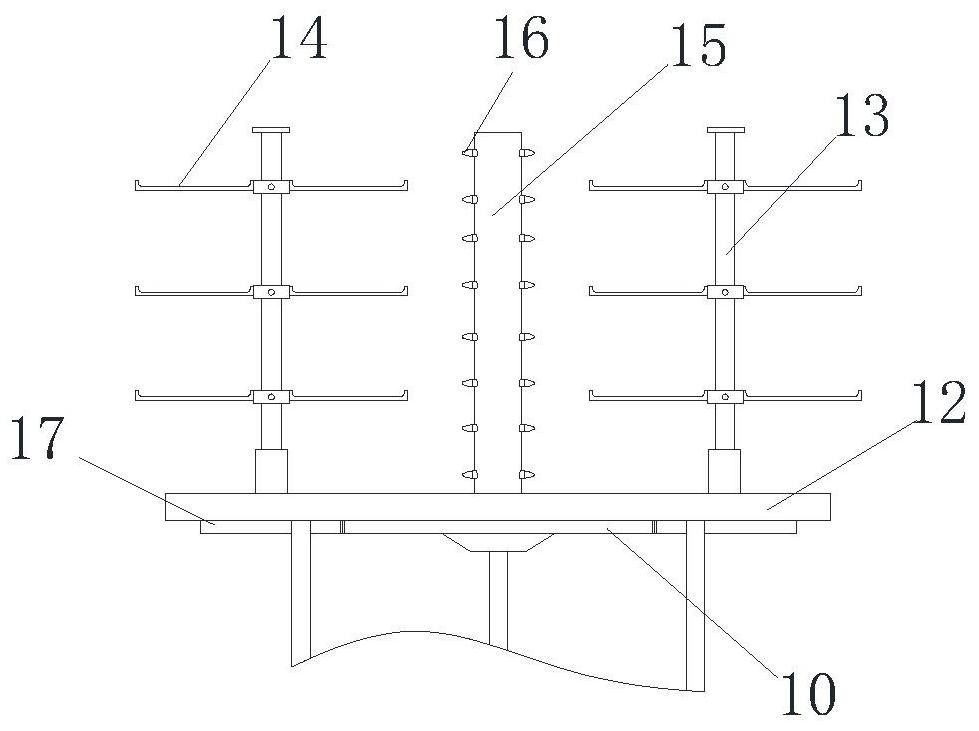

Image

Examples

Embodiment 1

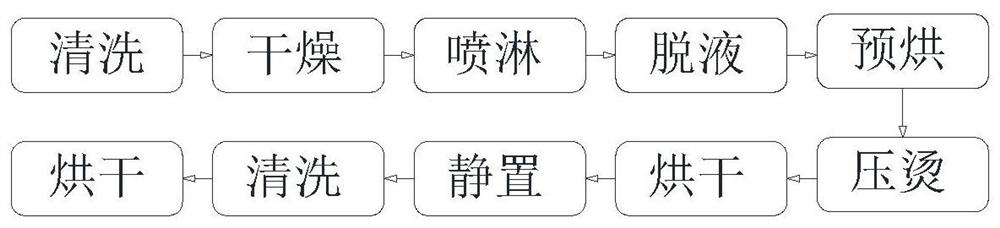

[0067] Taking the pure cotton fabric whose warp and weft yarns are 80-inch strands and has a warp and weft density of 130*90 strands / inch as an example, the non-ironing finishing method includes the following steps:

[0068] Step 1. Cleaning: wash the cotton fabric with water to remove organic and inorganic impurities on the surface of the cotton fabric;

[0069] Step 2, drying: dry the cotton fabric treated in step 1 at 40-55°C for 25-35 minutes;

[0070] Step 3, spraying: Spray the finishing solution on the cotton fabric treated in step 2 in the injection device, so that the surface of the cotton fabric is evenly liquid-treated. The finishing solution includes the following components and the mass concentrations of each component are respectively: Polyethylene emulsion 36g / L; Polyurethane 22g / L; Urea 7g / L; Amino acid oil 35 / L; Hydrophilic silicone softener 10g / L; Catalyst 15.5g / L; Penetrant 1g / L; Methyl urea resin 165g / L; the balance is water.

[0071] Step 4: deliquificat...

Embodiment 2

[0080] Taking a pure cotton fabric with a warp and weft count of 100 strands and a warp and weft density of 130*90 strands / inch as an example, the non-ironing finishing method includes the following steps:

[0081] Step 1. Cleaning: wash the cotton fabric with water to remove organic and inorganic impurities on the surface of the cotton fabric;

[0082] Step 2, drying: drying the cotton fabric treated in step 1 at 55°C for 25 minutes;

[0083] Step 3, spraying: Spray the finishing solution on the cotton fabric treated in step 2 in the injection device, so that the surface of the cotton fabric is evenly liquid-treated. The finishing solution includes the following components and the mass concentrations of each component are respectively: Polyethylene emulsion 40g / L; polyurethane 22g / L; urea 8g / L; amino acid oil 45 / L; hydrophilic silicone softener 10g / L; catalyst 15.5g / L; penetrant 1g / L; Methyl urea resin 160g / L; The balance is water;

[0084] Step 4: dehydration: deliquoring ...

Embodiment 3

[0093] Taking a pure cotton fabric with a warp and weft count of 120 strands and a warp and weft density of 130*90 strands / inch as an example, the non-ironing finishing method includes the following steps:

[0094] Step 1. Cleaning: wash the cotton fabric with water to remove organic and inorganic impurities on the surface of the cotton fabric;

[0095] Step 2, drying: drying the cotton fabric treated in step 1 at 47°C for 30 minutes;

[0096] Step 3, spraying: Spray the finishing solution on the cotton fabric treated in step 2 in the injection device, so that the surface of the cotton fabric is evenly liquid-treated. The finishing solution includes the following components and the mass concentrations of each component are respectively: Polyethylene emulsion 43g / L; Polyurethane 24g / L; Urea 8.5g / L; Amino acid oil 35 / L; Hydrophilic silicone softener 10g / L; Catalyst 15g / L; Penetrant 1g / L; Methyl urea resin 150g / L; The balance is water;

[0097] Step 4: Dehydration: deliquoring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com