Moringa seed micro-molecule polypeptide and preparation process thereof

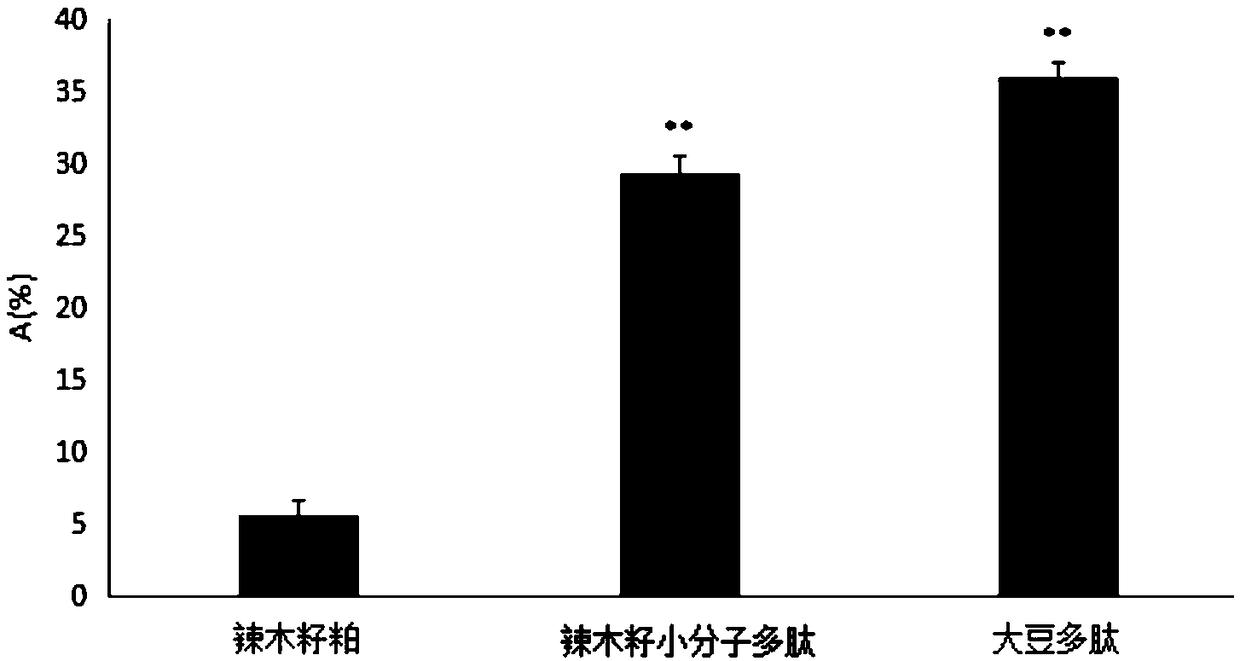

A technology of small molecular polypeptide and preparation process, which is applied in the field of small molecular polypeptide of Moringa seed and its preparation, and can solve the problems of poor absorption performance and low polypeptide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides a small molecule polypeptide of Moringa oleifera seed, which is prepared according to the following preparation process:

[0052] Step 1. Moringa oleifera seed meal and water are in a mass ratio of 1:15, heated to 100°C, and homogenized for 1 hour to obtain a slurry.

[0053] Step 2, the slurry is cooled to 55° C., and under natural pH conditions, neutral protease solid powder accounting for 3% of the quality of Moringa oleifera seed meal and alkaline protease solid powder accounting for 3% of the quality of Moringa oleifera seed meal are added to the slurry, Enzymolysis was performed for 6 hours to obtain an enzymolysis solution.

[0054] Step 3. Inactivate the enzyme solution at 100°C for 15 minutes, and filter to obtain a filtrate.

[0055] Step 4. Concentrate the filtrate in vacuum at a vacuum degree of 0.065.

[0056] Step 5, spray drying, control the process parameters as follows: air inlet temperature 185°C, air outlet temperature 87°C,...

Embodiment 2

[0059] This embodiment provides a small molecule polypeptide of Moringa oleifera seed, which is prepared according to the following preparation process:

[0060] Step 1. Mix Moringa oleifera seed meal with water at a mass ratio of 1:10, heat to 90°C, and homogenize for 2 hours to obtain a slurry.

[0061] Step 2, cooling the slurry to 50° C., under natural pH conditions, adding neutral protease solid powder accounting for 4% of the mass of Moringa oleifera seed meal and alkaline protease solid powder accounting for 1% of the mass of Moringa oleifera seed meal in the slurry, Enzymolysis was performed for 6 hours to obtain an enzymolysis solution.

[0062] Step 3. Inactivate the enzyme solution at 100°C for 10 minutes, and filter to obtain a filtrate.

[0063] Step 4. Concentrate the filtrate in vacuum at a vacuum degree of 0.06.

[0064] Step 5, spray drying, control the process parameters as follows: air inlet temperature 180°C, air outlet temperature 70°C, wind-introduced r...

Embodiment 3

[0067] This embodiment provides a small molecule polypeptide of Moringa oleifera seed, which is prepared according to the following preparation process:

[0068] Step 1. Moringa oleifera seed meal is mixed with water at a mass ratio of 1:20, heated to 100°C, and homogenized for 0.5 h to obtain a slurry.

[0069] Step 2, cooling the slurry to 60° C., under natural pH conditions, adding neutral protease solid powder accounting for 1% of the mass of Moringa oleifera seed meal and alkaline protease solid powder accounting for 4% of the mass of Moringa oleifera seed meal in the slurry, Enzymolysis was performed for 6 hours to obtain an enzymolysis solution.

[0070] Step 3. Inactivate the enzyme solution at 100°C for 10 minutes, and filter to obtain a filtrate.

[0071] Step 4. Concentrate the filtrate in vacuum at a vacuum degree of 0.08.

[0072] Step 5, spray drying, control the process parameters as follows: air inlet temperature 190°C, air outlet temperature 95°C, wind-intro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com