Method for rapidly non-crystallizing flash hot organic kaolin

An organic kaolin and amorphization technology, applied in chemical instruments and methods, inorganic chemistry, chemical industry, etc., can solve the problems of high energy consumption, many impurities, low efficiency of amorphous kaolin, etc., and achieve convenient operation, simple preparation process, The effect of heating product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

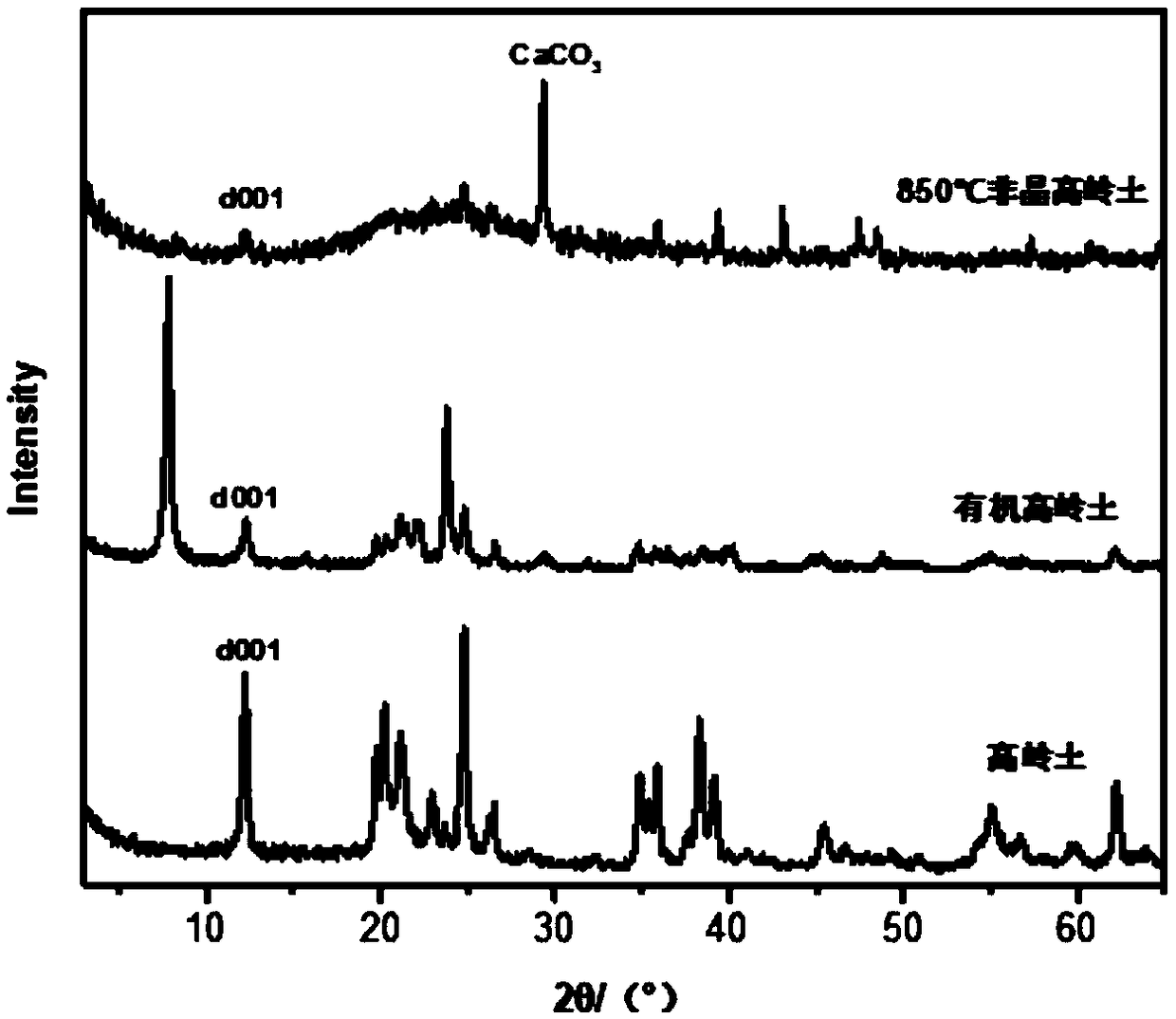

Embodiment 1

[0029] Crushing and grinding the raw kaolin into powder, passing through a 600-mesh sieve, controlling its average particle size to be less than 25 microns, and placing the sieved kaolin powder in a blast drying oven at 80°C for 24 hours. The organic kaolin was prepared by reacting the dried kaolin and dimethyl sulfoxide at a mass volume ratio of 1:6 g / ml at 50° C. for 72 hours, and the intercalation rate was over 85%. The product organic kaolin was ground in a mortar for 30 min, and then placed in a blast drying oven at 80 °C for 24 h. The treated organic kaolin sample was then placed in a powder spray gun, and the organic kaolin powder was sprayed into a 650°C vertical heating furnace. A feeding tube is placed in the heating furnace, and the length of the feeding tube is adjusted so that the distance from the hot zone is 30cm, and the residence time of the material in the hot zone is 0.1s. The material falls into the collector through the feeding pipe, and is stored in a dr...

Embodiment 2

[0031] Crushing and grinding the raw kaolin into powder, passing through an 800-mesh sieve, controlling its average particle size to be less than 18 microns, and placing the sieved kaolin powder in a blast drying oven at 60°C for 30 hours. The organic kaolin is prepared by reacting the dried kaolin and dimethyl sulfoxide at a mass volume ratio of 1:8 g / ml at 50° C. for 72 hours, and the intercalation rate is over 85%. The product organic kaolin was ground in a mortar for 30 min, and then placed in a blast drying oven at 60 °C for 30 h. The treated organic kaolin sample was then placed in a powder spray gun, and the organic kaolin powder was sprayed into a vertical heating furnace at 750°C. A feeding tube is placed in the heating furnace, and the length of the feeding tube is adjusted so that the distance from the hot zone is 30cm, and the residence time of the material in the hot zone is 0.1s. The material falls into the collector through the feeding pipe, and is stored in a ...

Embodiment 3

[0033] Crushing and grinding the raw kaolin into powder, passing through an 800-mesh sieve, controlling its average particle size to be less than 18 microns, and placing the sieved kaolin powder in a blast drying oven at 60°C for 30 hours. The organic kaolin is prepared by reacting the dried kaolin and dimethyl sulfoxide at a mass volume ratio of 1:10 g / ml at 50° C. for 72 hours, and the intercalation rate is over 85%. The product organic kaolin was ground in a mortar for 30 min, and then placed in a blast drying oven at 60 °C for 30 h. The treated organic kaolin sample was then placed in a powder spray gun, and the organic kaolin powder was sprayed into a vertical heating furnace at 850°C. A feeding tube is placed in the heating furnace, and the length of the feeding tube is adjusted so that the distance from the hot zone is 40cm, and the residence time of the material in the hot zone is 0.2s. The material falls into the collector through the feeding pipe, and is stored in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com