Method for recovering gold from flotation tailings

A technology for flotation tailings and gold recovery, applied in flotation, solid separation and other directions, can solve problems such as high recovery rate, and achieve the effects of high separation index, low cost, and easy management and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

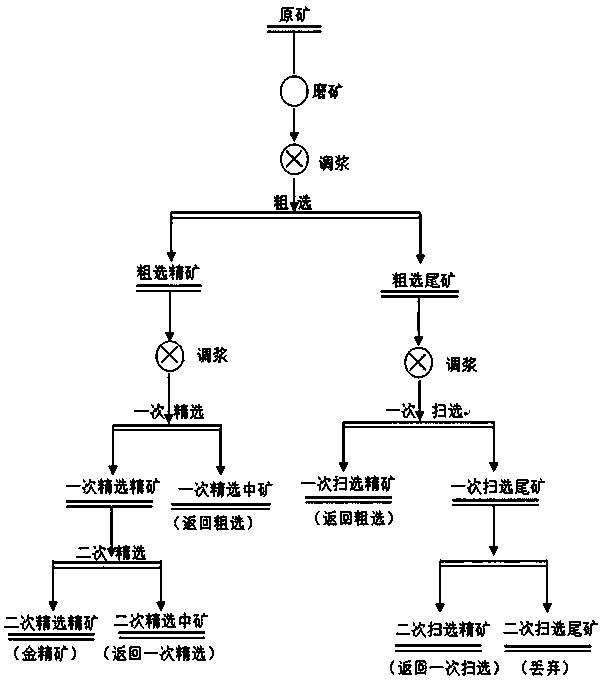

Method used

Image

Examples

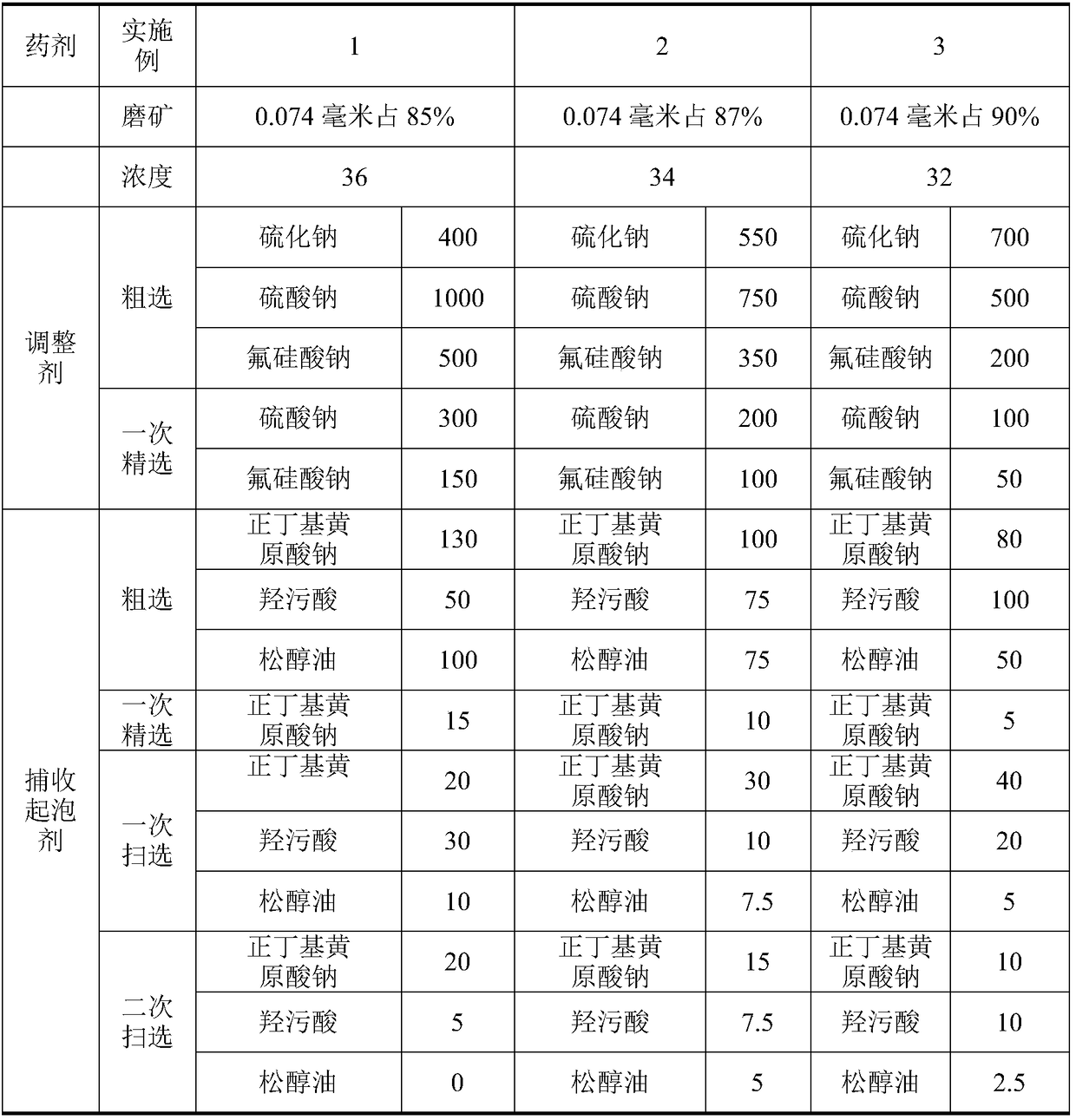

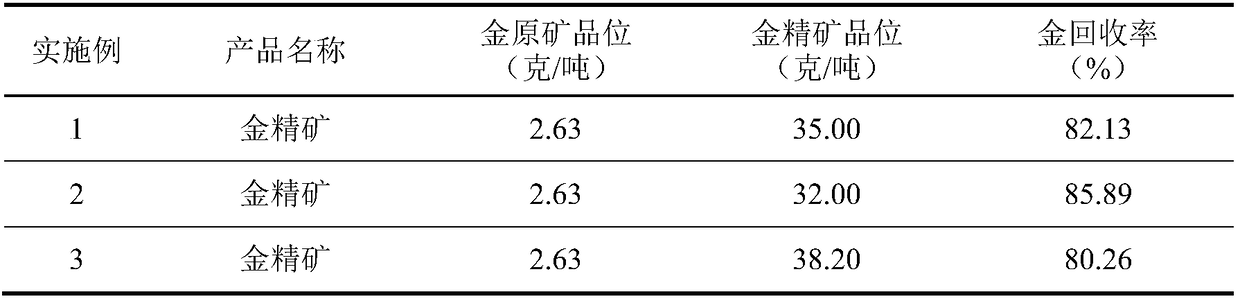

Embodiment 1

[0021] A flotation tailings was used as raw ore for flotation gold separation, and the gold grade of the flotation tailings was 2.63 g / t. The recyclable element is gold, and pyrite is the main carrier mineral of gold. The distribution of gold ore in the carrier mineral is uneven, some are distributed in groups, most of them are scattered, and they are mostly filled between pyrite and other sulfide particles. Thinner, more difficult to float. Wherein the beneficiation steps of gold minerals are:

[0022] 1) Grinding: Grinding gold minerals, that is, raw ore, to a fineness of 0.074 mm, accounting for 85%, adjusting the concentration of the slurry to 36%;

[0023] 2) Rough selection: add gold mineral regulator per ton of raw ore: sodium sulfide 400g / t, sodium sulfate 1000g / t, sodium fluorosilicate 500g / t; collecting foaming agent per ton of raw ore: n-butyl Sodium xanthate 130g / t, hydroxyacid 50g / t, pinitol oil 100g / t. The flotation tailings are used as a scavenging feed, and ...

Embodiment 2

[0030] Raw ore is with embodiment one, and the beneficiation step of gold mineral is:

[0031] 1) Grinding: Grinding gold minerals, that is, raw ore, to a fineness of 0.074 mm, accounting for 87%, adjusting the slurry concentration to 34%;

[0032] 2) Rough selection: add gold mineral regulator per ton of raw ore: sodium sulfide 550g / t, sodium sulfate 750g / t, sodium fluorosilicate 350g / t; collecting foaming agent per ton of raw ore: n-butyl Sodium xanthate 100g / t, hydroxyacid 75g / t, terpineol oil 75g / t. The gold flotation tailings are used as a scavenging feed, and the flotation coarse concentrate is used as a beneficiation feed;

[0033] 3) One-time beneficiation: add gold mineral regulator to the rougher concentrate slurry, calculated per ton of raw ore: sodium sulfate 200g / t, sodium fluorosilicate 100g / t; collecting foaming agent per ton of raw ore: positive Sodium butyl xanthate 10g / t, the primary beneficiation concentrate is used as the ore for the secondary beneficiati...

Embodiment 3

[0039] Raw ore is with embodiment one, and the beneficiation step of gold mineral is:

[0040] 1) Grinding: Grinding gold minerals, that is, raw ore, to a fineness of 0.074 mm, accounting for 90%, adjusting the concentration of the slurry to 32%;

[0041] 2) Rough selection: add gold mineral regulator per ton of raw ore: sodium sulfide 700g / t, sodium sulfate 500g / t, sodium fluorosilicate 200g / t; collecting foaming agent per ton of raw ore: n-butyl Sodium xanthate 80g / t, hydroxyacid 100g / t, pinitol oil 50g / t. The gold flotation tailings are used as a scavenging feed, and the flotation coarse concentrate is used as a beneficiation feed;

[0042] 3) One-time beneficiation: adding gold mineral regulator to the rougher concentrate pulp: 100g / t sodium sulfate, 50g / t sodium fluorosilicate; Sodium butyl xanthate 5g / t, the primary beneficiation concentrate is used as the secondary beneficiation ore, and the primary beneficiation medium ore returns to the roughing step to form a close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com