Glycopeptide or glycoprotein enrichment material, preparation thereof and application of material

A glycoprotein enrichment technology, applied in the application field of glycoproteomics, can solve the problems of inapplicable O-type glycosylation site identification, lack of glycosidase, etc., and achieve mild reaction conditions and good particle dispersion , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of mercaptopolymer spheres: In a 5mL centrifuge tube, add 2mL of phosphate buffer solution PB (50mM, pH8), add 30μg of polystyrene particles with a particle size of 10μm and aldehyde groups on the surface, ultrasonically disperse evenly, Add 200mg of CD (2,2'-dithiodiethylamine), 10mg of sodium cyanoborohydride, react with a constant temperature oscillator at 30°C for 24h, and stop the reaction. Centrifuge at a speed of 3000 rad / min in a high-speed centrifuge, remove the supernatant, wash with water and Tris-HCl buffer solution with pH 8 in turn for 4 times, dry in a vacuum oven at 50°C for 24 hours, and redisperse in phosphate buffer solution Add 0.1mg of tris(2-carboxyethyl)phosphine (TCEP) to PB (50mM, pH 8), shake and react at 40°C for 1h, centrifuge at a speed of 3000rad / min in a high-speed centrifuge, remove the supernatant, and then use Wash 3 times with water and dry in a vacuum oven to constant weight. Polymer particles modified with mercapto group...

Embodiment 2

[0023] Preparation of mercaptosilica spheres: In a 150mL round bottom flask, add 50mL of toluene, add 2.5g of silica gel particles with a particle size of 5μm, and 1ml of 3-mercaptopropyltriethoxysilane, and disperse evenly by ultrasonication for 2 minutes. A condenser was connected to the flask, and mechanically stirred at a speed of 300 rad / min. The reaction device was placed in an oil bath, heated to reflux at 110°C for 15 hours, the reaction was stopped, and cooled to room temperature. Centrifuge at a speed of 3000 rad / min in a high-speed centrifuge, remove the supernatant, use toluene, acetone, methanol, and acetone to filter and wash successively, repeat the suction and filter washing for 3 times, and dry in a vacuum oven at 50°C for 16 hours to obtain Silica gel particles modified with mercapto groups.

Embodiment 3

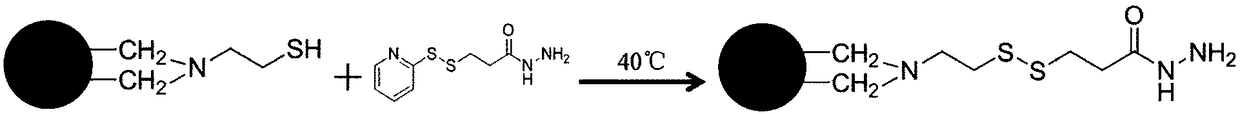

[0025] Preparation of hydrazide microspheres: Disperse 25 mg of the mercapto microsphere particles obtained in Example 1 in a PB buffer solution of pH 7.8, and disperse evenly by ultrasonication, add 10 mg of PDPH (3-(2-pyridyldithio)propionyl hydrazide), and disperse by ultrasonication , shake and react at 30°C for 16 hours; then use a high-speed centrifuge to centrifuge at a speed of 3500rad / min for 5min, remove the supernatant, wash the microspheres with reaction solvent, water, and 50mM sodium acetate in sequence, repeat the washing 3 times, and dry in vacuum In the box to constant weight, the sugar chain-releasable glycosylated peptide / protein enrichment material is obtained. The preparation process is as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com